Processing method for carving hollow applique/embroider in textile

A processing method and fabric technology, applied to the mechanism of embroidery machines, embroidery machines, textile decoration, etc., can solve the problems of complex varieties, fabric waste, low efficiency, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

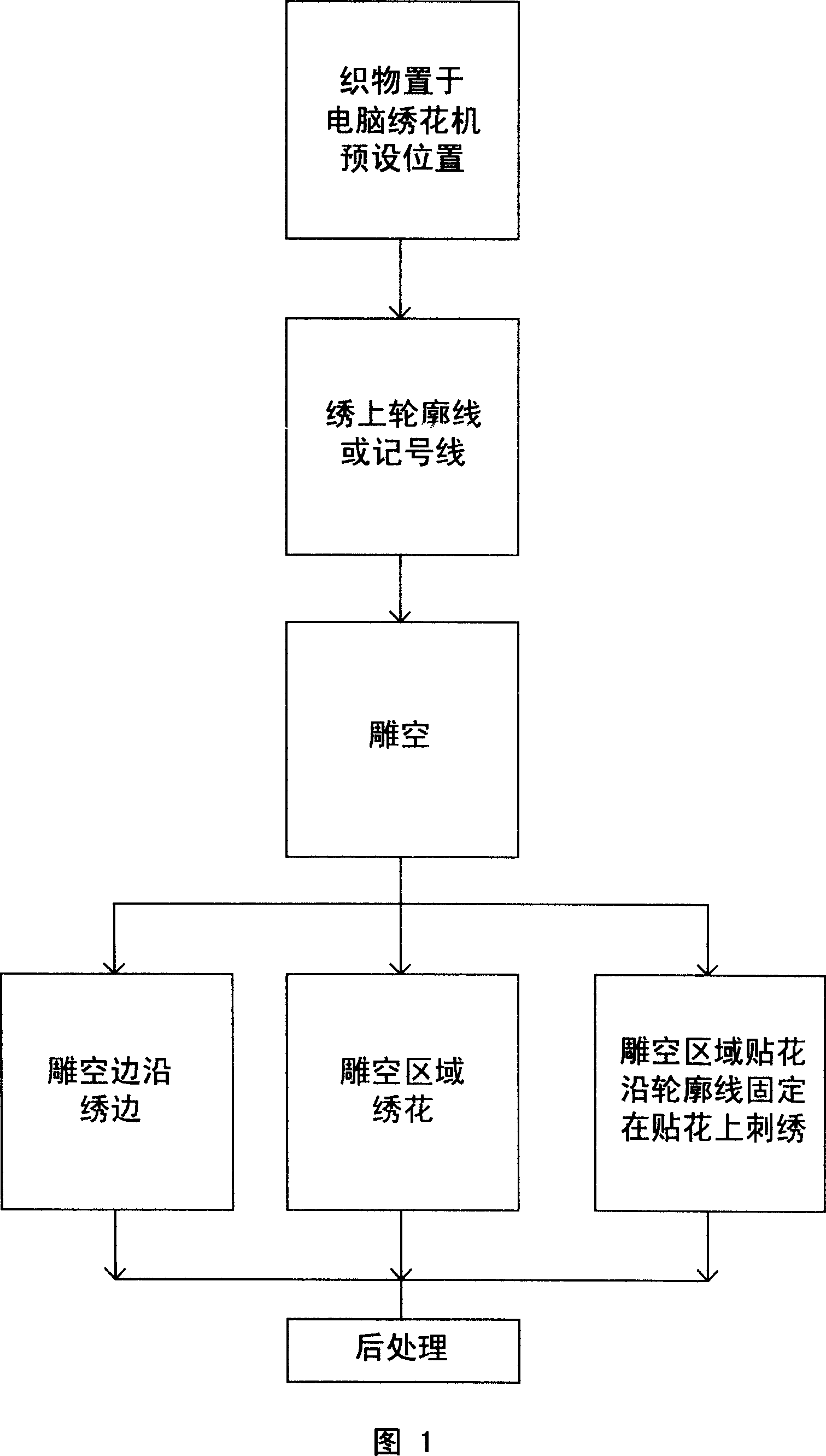

[0022] As shown in Figure 1, a processing method for carving empty appliques\embroideries on fabrics, adopts the following steps:

[0023] a) Place the fabric (cloth, mesh, ribbon) at the preset position of the computerized embroidery machine, and lay water-soluble paper or hot glue on the bottom of the fabric to prevent the fabric from moving;

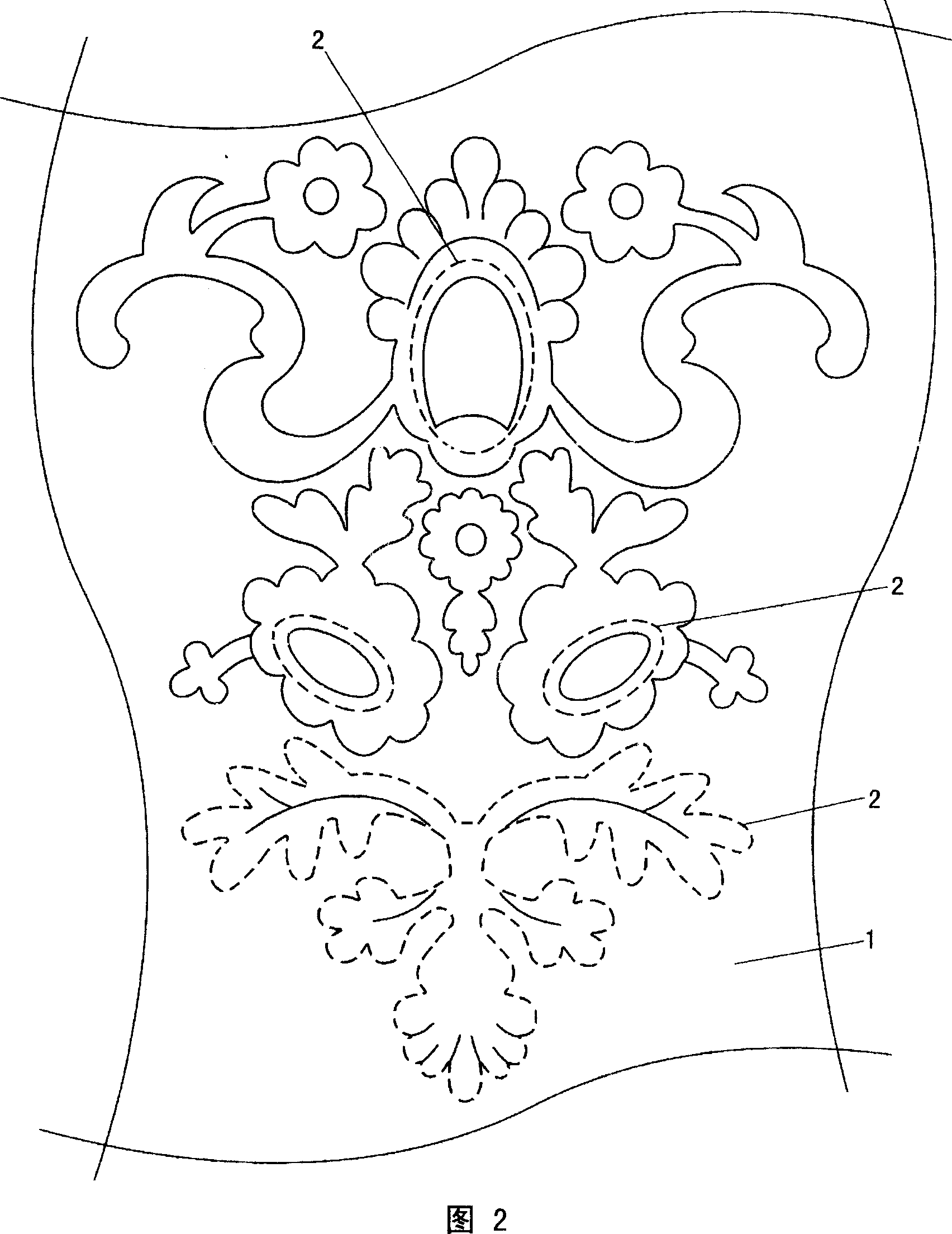

[0024] b) Embroider contour lines or marking lines on the positions where the fabric needs to be carved or appliquéd;

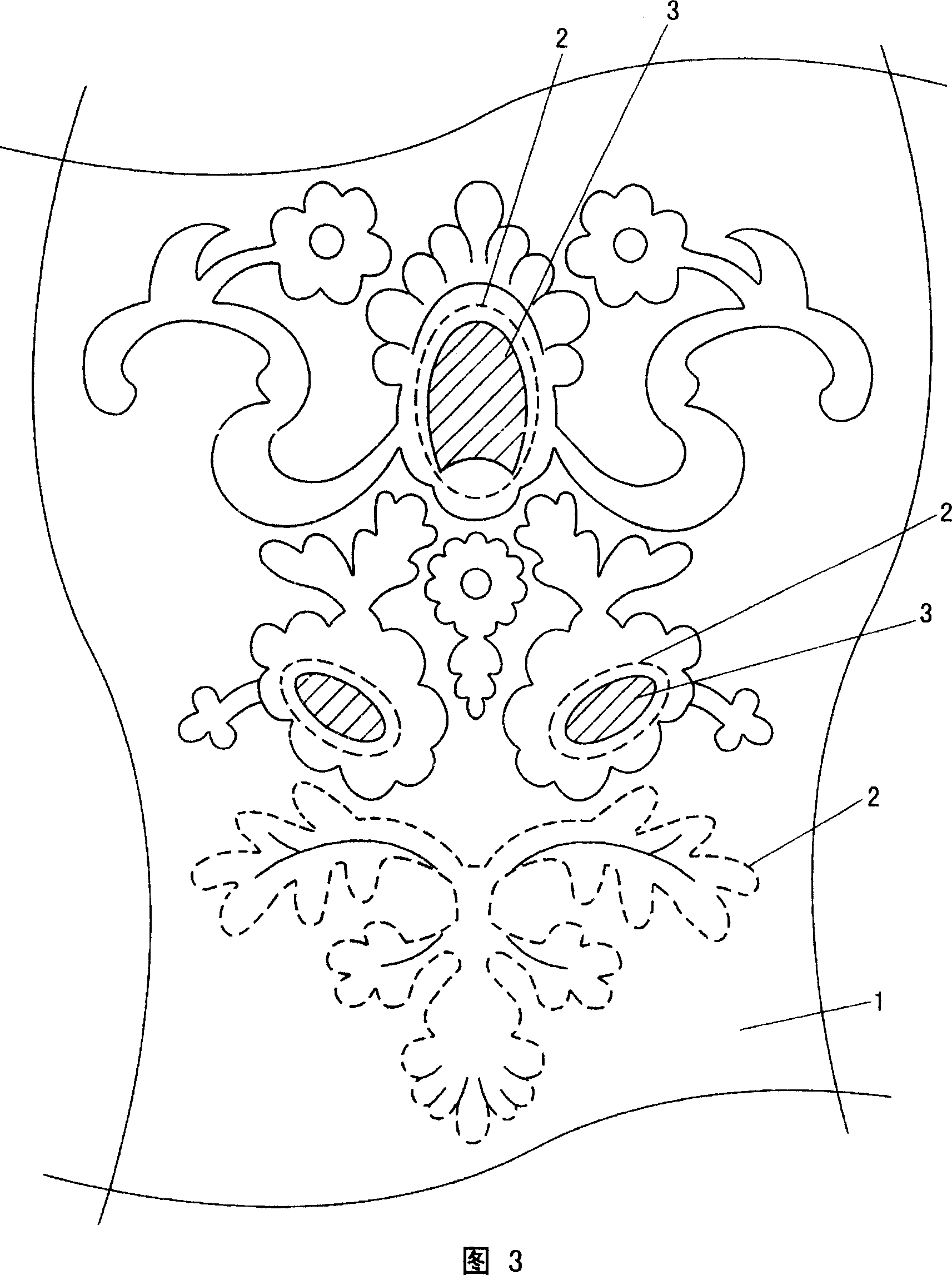

[0025] c) Carve out the fabric in the contour line or mark line area with a sharp tool such as a blade;

[0026] d) The embroidery machine directly embroiders along the outline or marking line according to the computer setting program;

[0027] Or the embroidery machine can directly embroider in the area inside the contour line or mark line according to the pattern input by the computer;

[0028] Or place the patch cut into appliqué pattern on the empty position of the fabric, and then the embroidery machine will l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com