Hot pipe

A heat pipe and cavity technology, applied in the field of heat transfer, can solve problems such as limiting the heat transfer efficiency of the heat pipe, and achieve the effect of improving the heat transfer efficiency and the heat transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

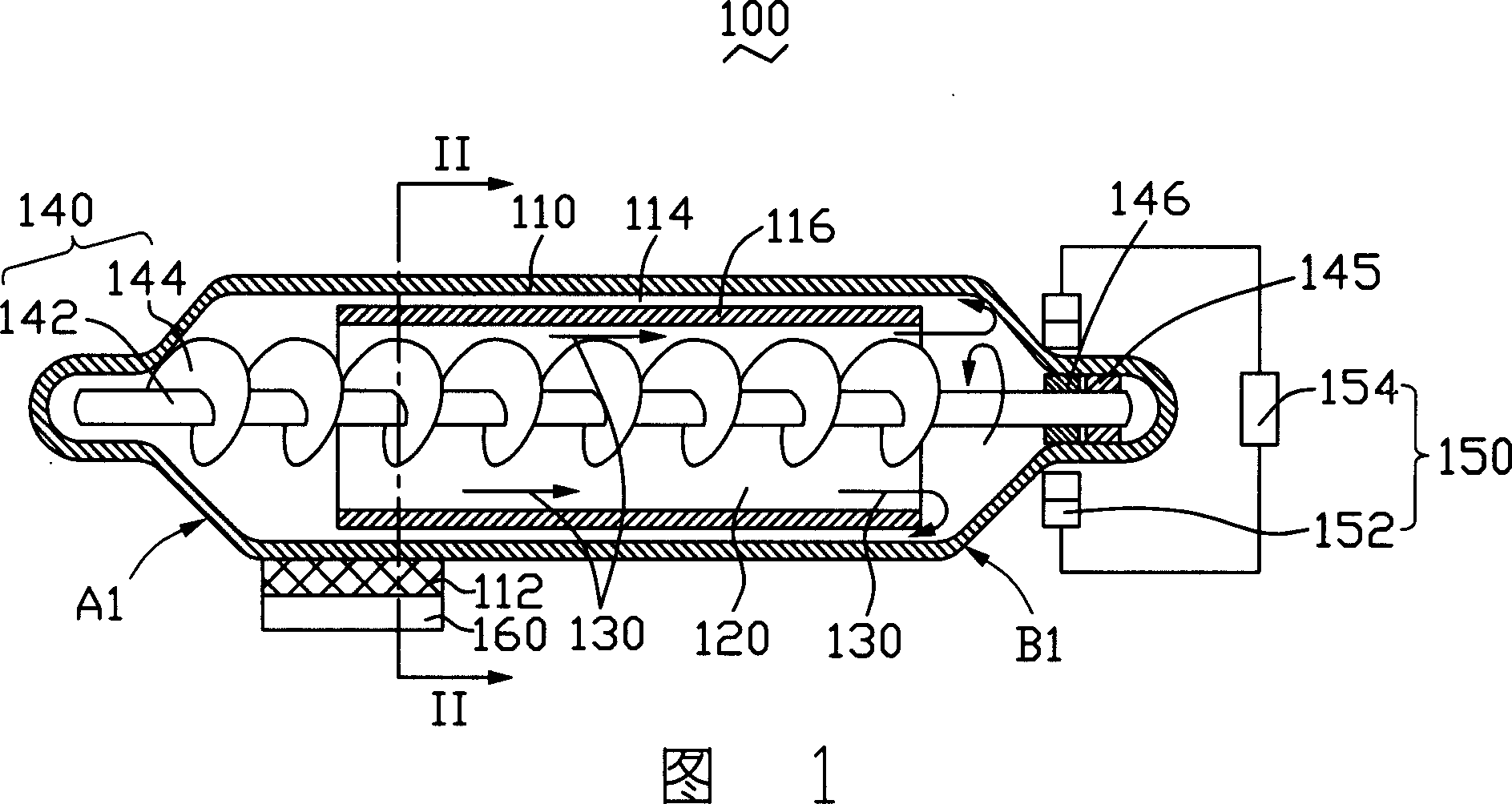

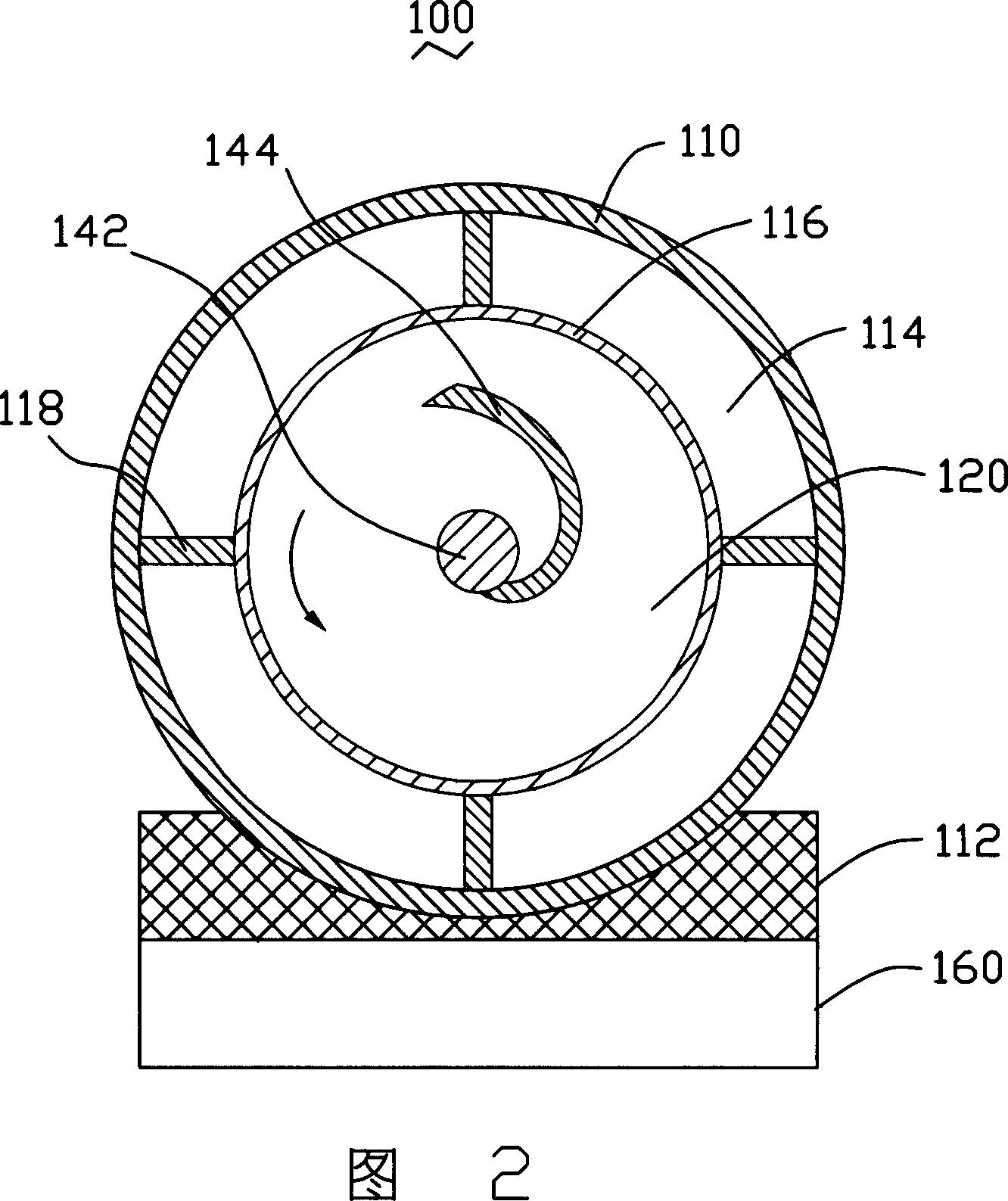

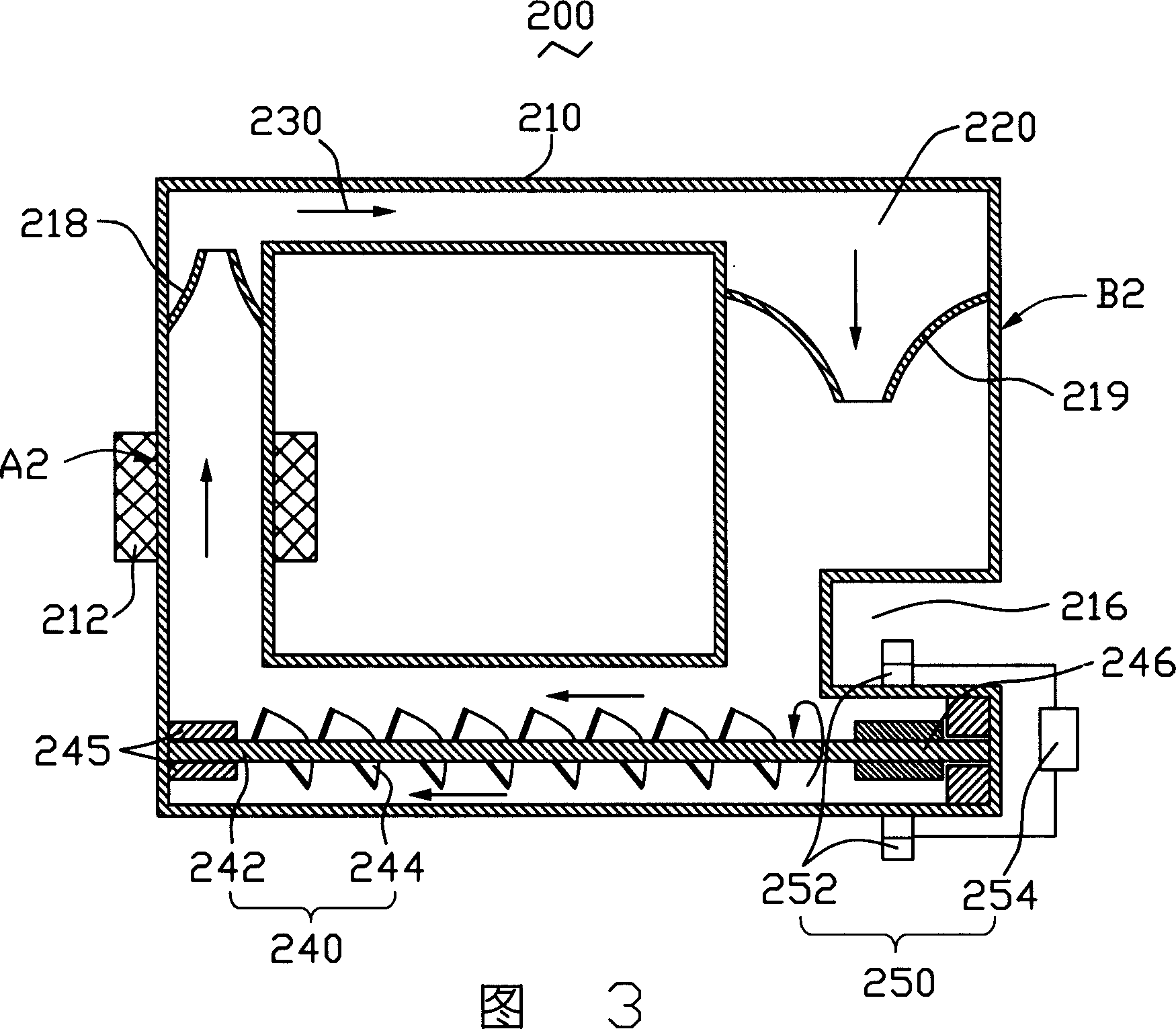

[0017] Please refer to Fig. 1 and Fig. 2 together, it is the first embodiment of the heat pipe of the present invention, and this heat pipe is a single pipe type heat pipe 100, comprises a hollow airtight casing 110, has a cavity 120 therein; The working fluid 130 in the heat pipe 110 ; a rotating device 140 arranged axially along the cavity 120 to accelerate the flow of the working fluid 130 in the heat pipe 100 ; and a driving device 150 arranged at one end of the casing 110 .

[0018] Wherein, the hollow airtight casing 110 usually includes an evaporating end A1 and a condensing end B1, the evaporating end A1 is in contact with a heat source 160, in order to increase the contact area between them, a heat dissipation patch 112 can be arranged at the evaporating end A1, When the heat pipe 100 is in use, the heat dissipation patch 112 is closely attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com