Combustor for stove

A technology for burners and stoves, which is applied in the direction of burners, gas fuel burners, and combustion methods. It can solve the problems of easy adhesion of soup to the flame hole, cumbersome maintenance of burners, etc., and achieve good maintainability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

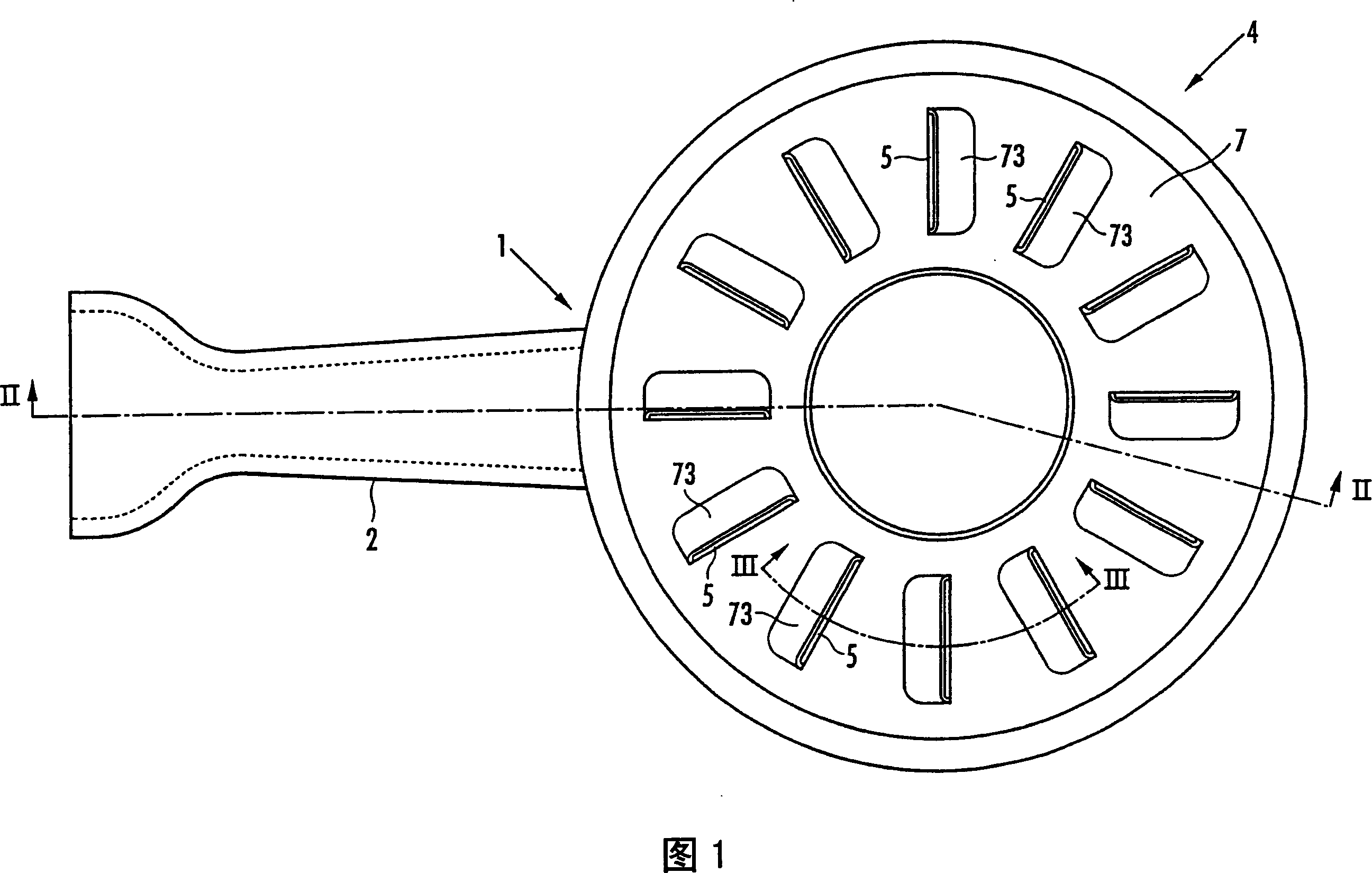

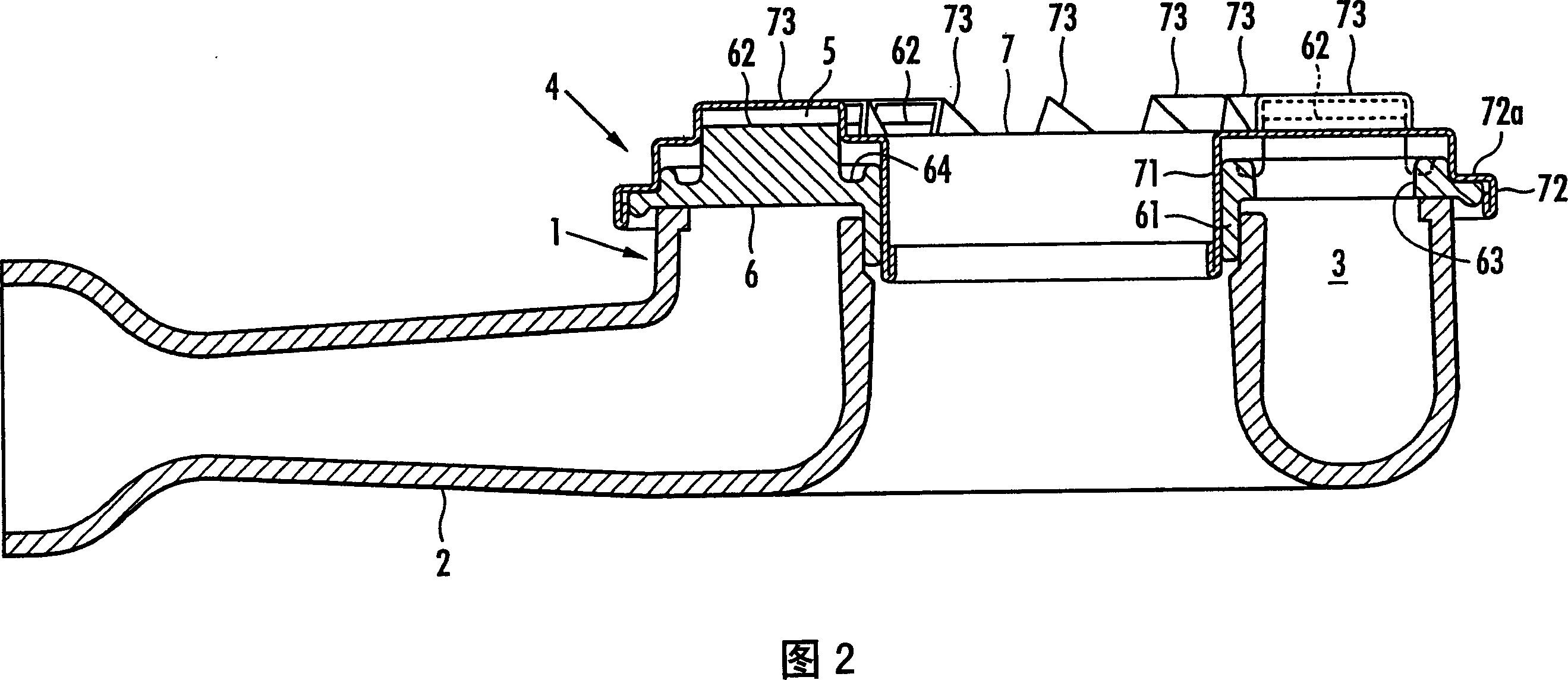

[0014] Referring to Fig. 1 and Fig. 2, 1 is a burner body of a burner for a stove. A mixing tube 2 is integrally formed on the burner body 1 . At the portion of the burner body 1 at the front end of the mixing tube 2, an annular gas distribution chamber 3 with an upward opening is formed. Furthermore, a burner roof 4 covering the gas distribution chamber 3 from above is provided. On the upper surface of the burner top cover 4, a plurality of radial flame holes 5 are arranged at intervals in the circumferential direction. The gas is caused to be ejected from each flame hole 5 with a motion component directed in one direction (counterclockwise in FIG. 1 ) in the circumferential direction.

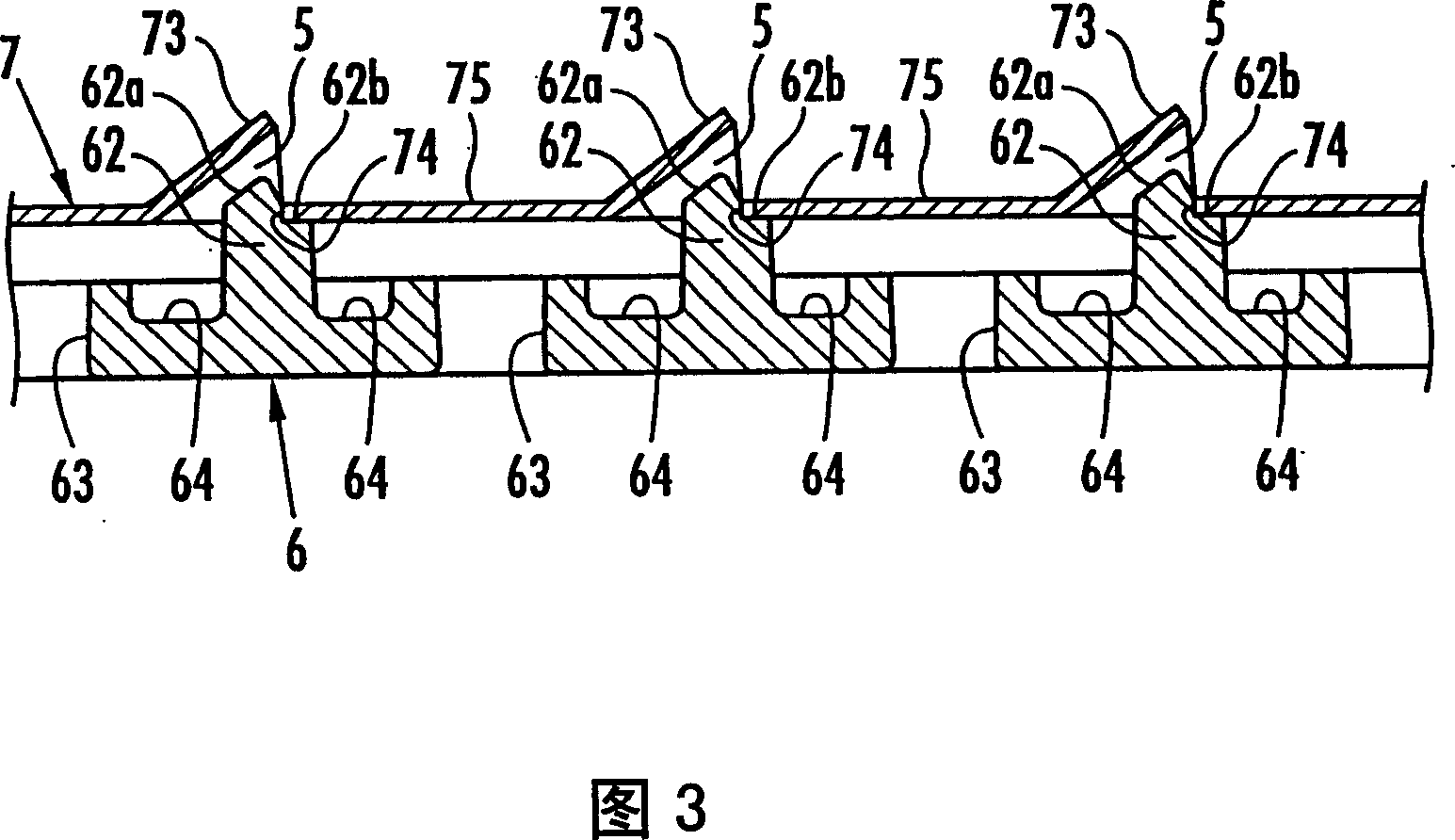

[0015] The burner ceiling 4 is composed of an annular lower plate member 6 placed on the burner body 1 , and an annular upper plate member 7 placed on the lower plate member 6 . The lower plate member 6 is a cast product, and a cylindrical portion 61 is vertically provided on the inner per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com