Adhesivetape box-sealing machine core

A sealing machine and adhesive tape technology, applied in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problem of affecting the cutting effect and efficiency of the tape sealing machine, the blade has no effective and practical protection, and the blade is vulnerable damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

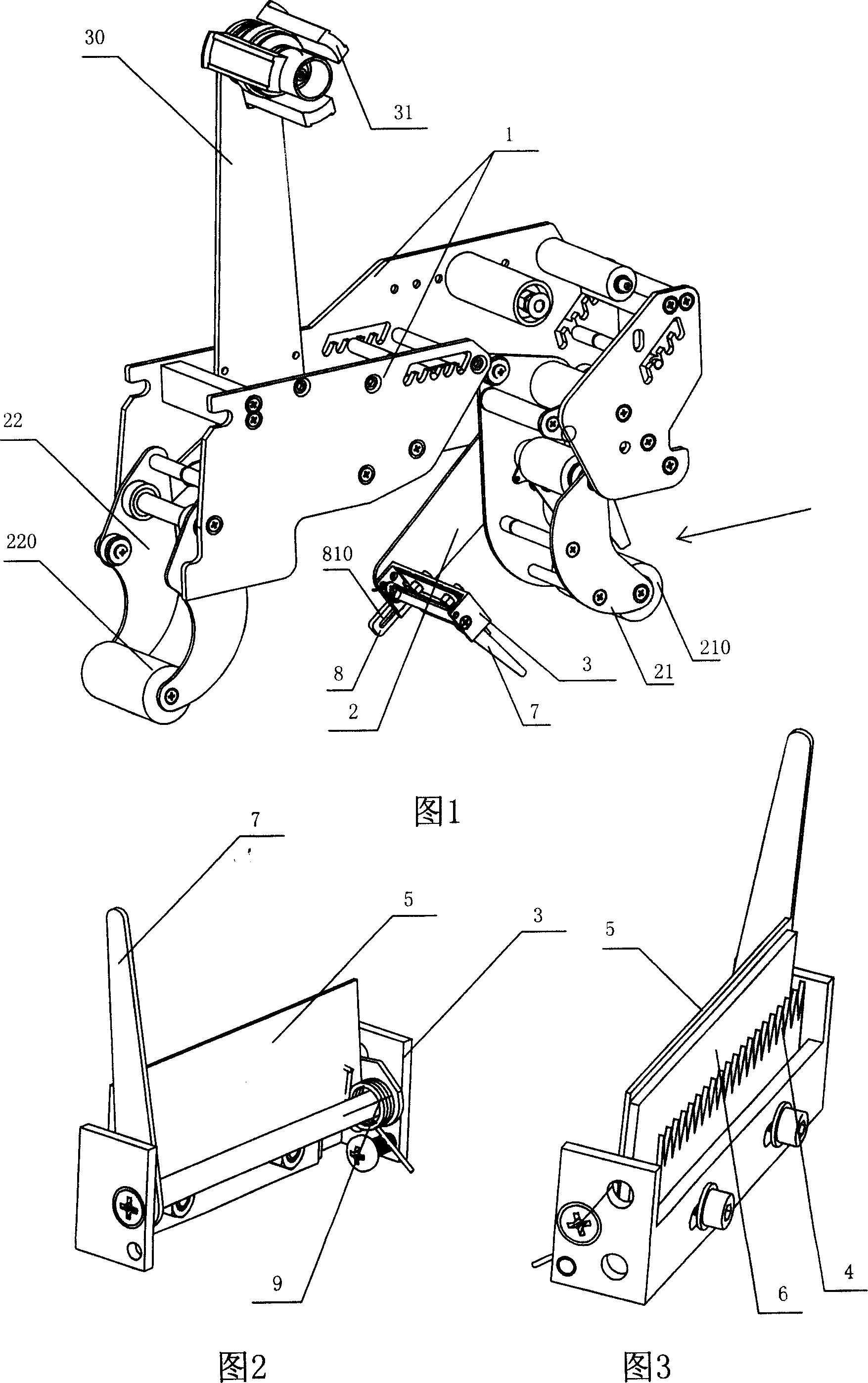

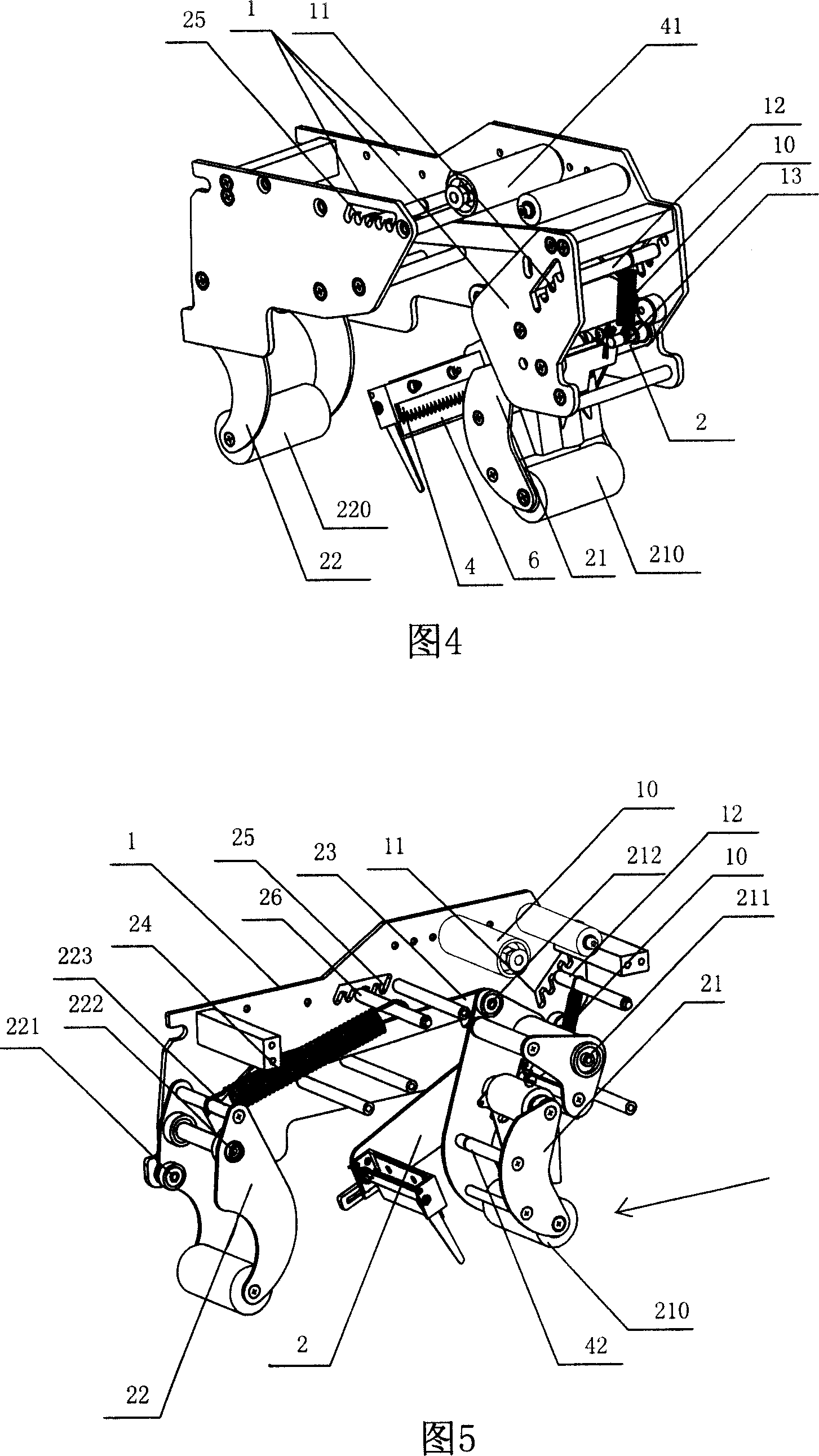

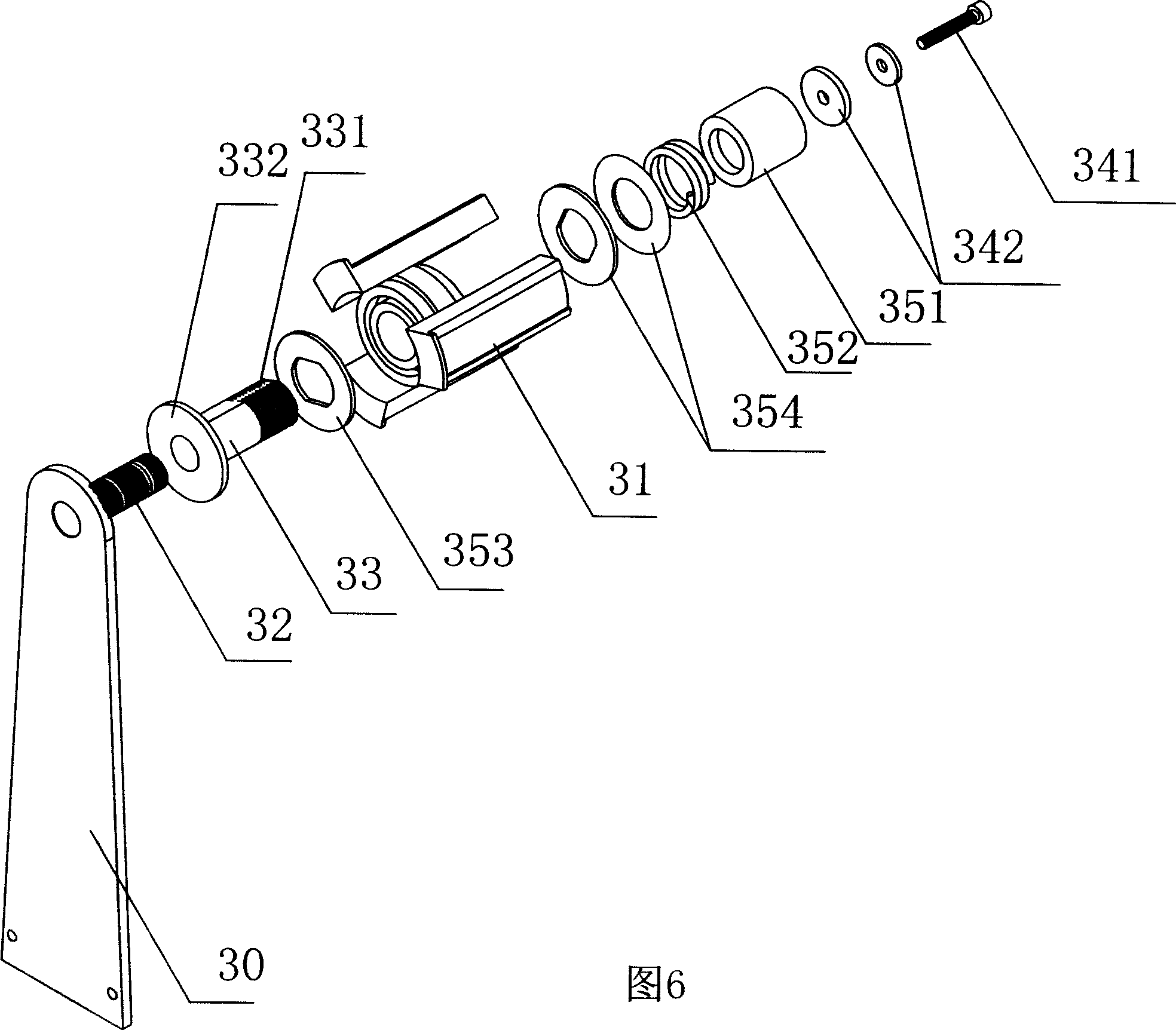

[0018] Refer to attached picture. The present invention comprises movement side plate 1, adhesive tape mounting device, pressure wheel device, tape cutting device, and described tape cutting device comprises rotatable knife rest 2, and one end of knife rest is connected with blade mounting frame 3, and blade mounting frame is installed with The blade 4, the blade mount is provided with a rotatable blade guard 5, the blade guard is at the back of the blade, and a blade pad 6 made of an oil-absorbing material is also provided between the blade guard and the blade. The blade guard is provided with a control lever 7 that delays the rotation and reset of the blade guard.

[0019] The material of blade pad can adopt the rubber with oil-absorbing property.

[0020] One end of the knife rest installation blade mount is provided with the adjustment bar 8 that regulates the tail length of the sealing tape.

[0021] Reference numeral 9 is the rotation return spring of the blade guard 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com