High-pressure by-pass valve

A technology of bypass valve and bypass channel, which is applied to multi-way valves, valve devices, engine components, etc., can solve problems such as poor stability, high noise, and large vibration, and achieve reduced vibration, safe and reliable work, and stable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

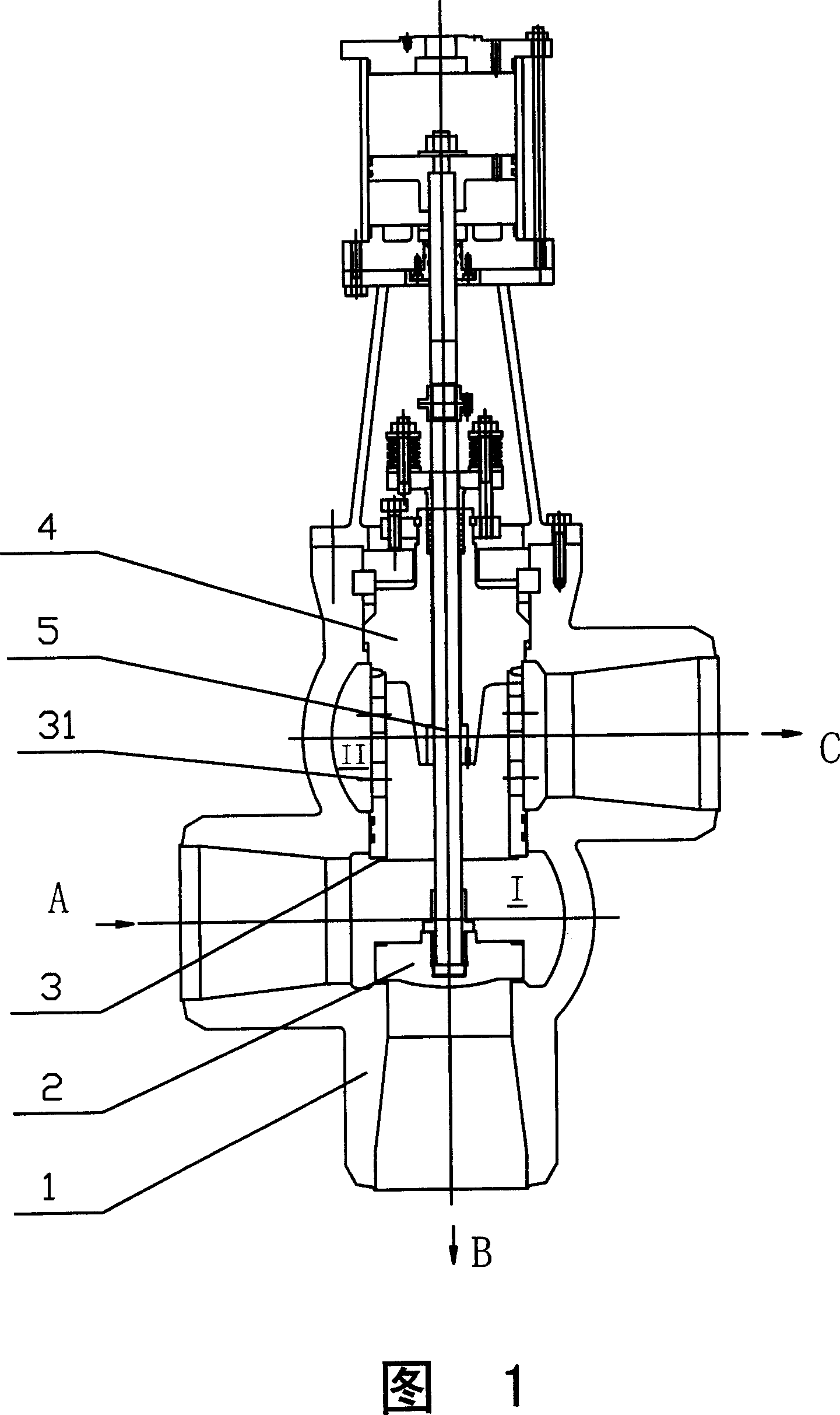

[0014] As shown in Fig. 1, the figure is a cross-sectional view of the high pressure bypass valve of the present invention. The valve includes a valve body 1, on which two connected chambers are formed, wherein the chamber I is the main channel chamber, and the chamber includes an inlet A and an outlet B, which are used as high-pressure bypass inlets When the valve is used, the inlet A is connected to the water inlet pipe, and the outlet B is connected to the inlet of the high pressure heater. A passageway chamber, which communicates with the main passageway chamber, and has a bypass port C, which is connected with a bypass passageway.

[0015] A disc 2 can move up and down in the longitudinal direction of the valve body 1, and when it is in the highest position, it will separate the bypass passage chamber from the main passage chamber and open the main passage; when it is in the lowest position, it will open the main passage. closed, the chamber of the bypass channel communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com