Motor

A motor and hollow core technology, applied in the field of motors, can solve the problems of uneven pressure, breakage, uneven pressure of the winding end 105b, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, an example of a motor to which the present invention is applied will be described with reference to the drawings.

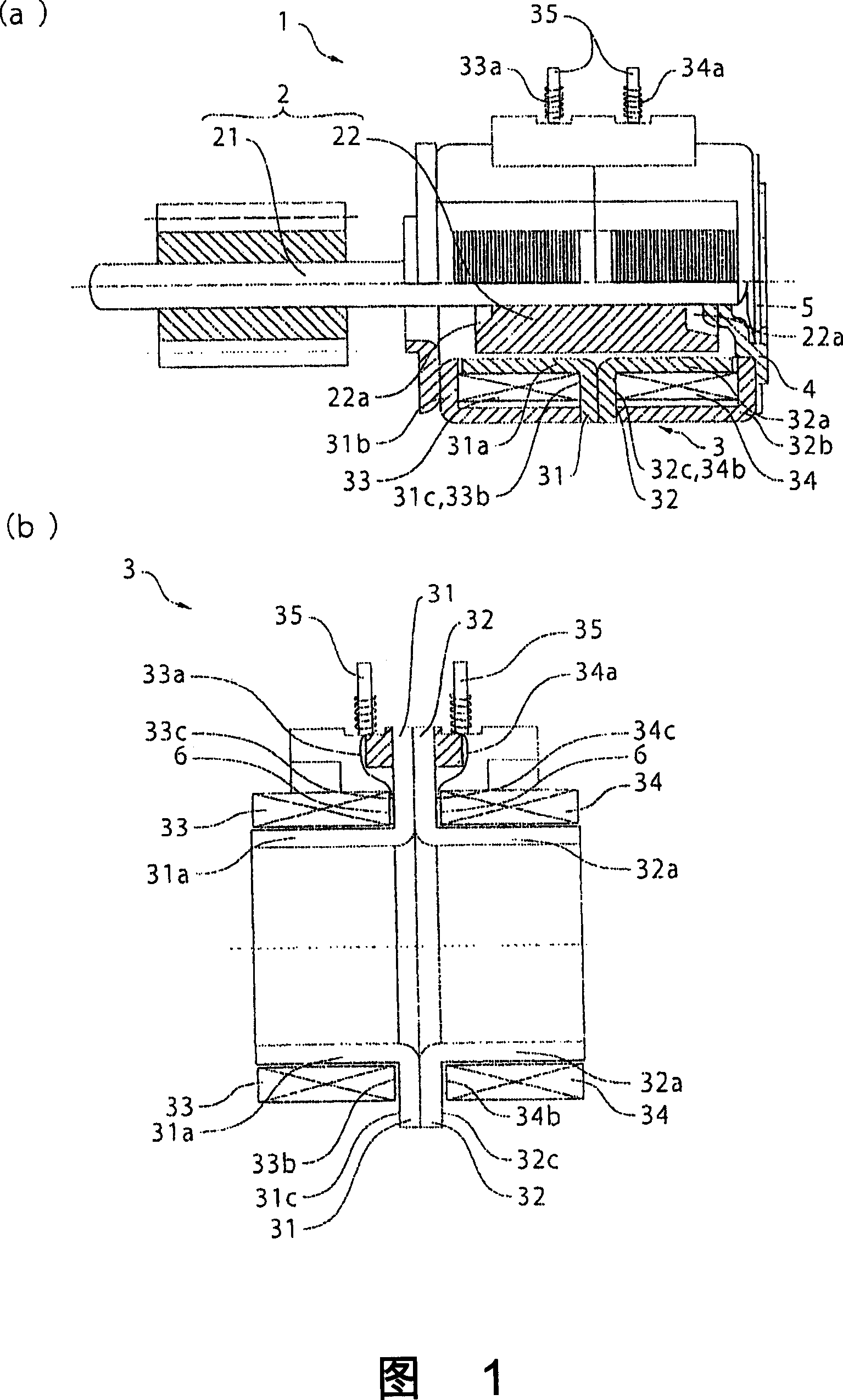

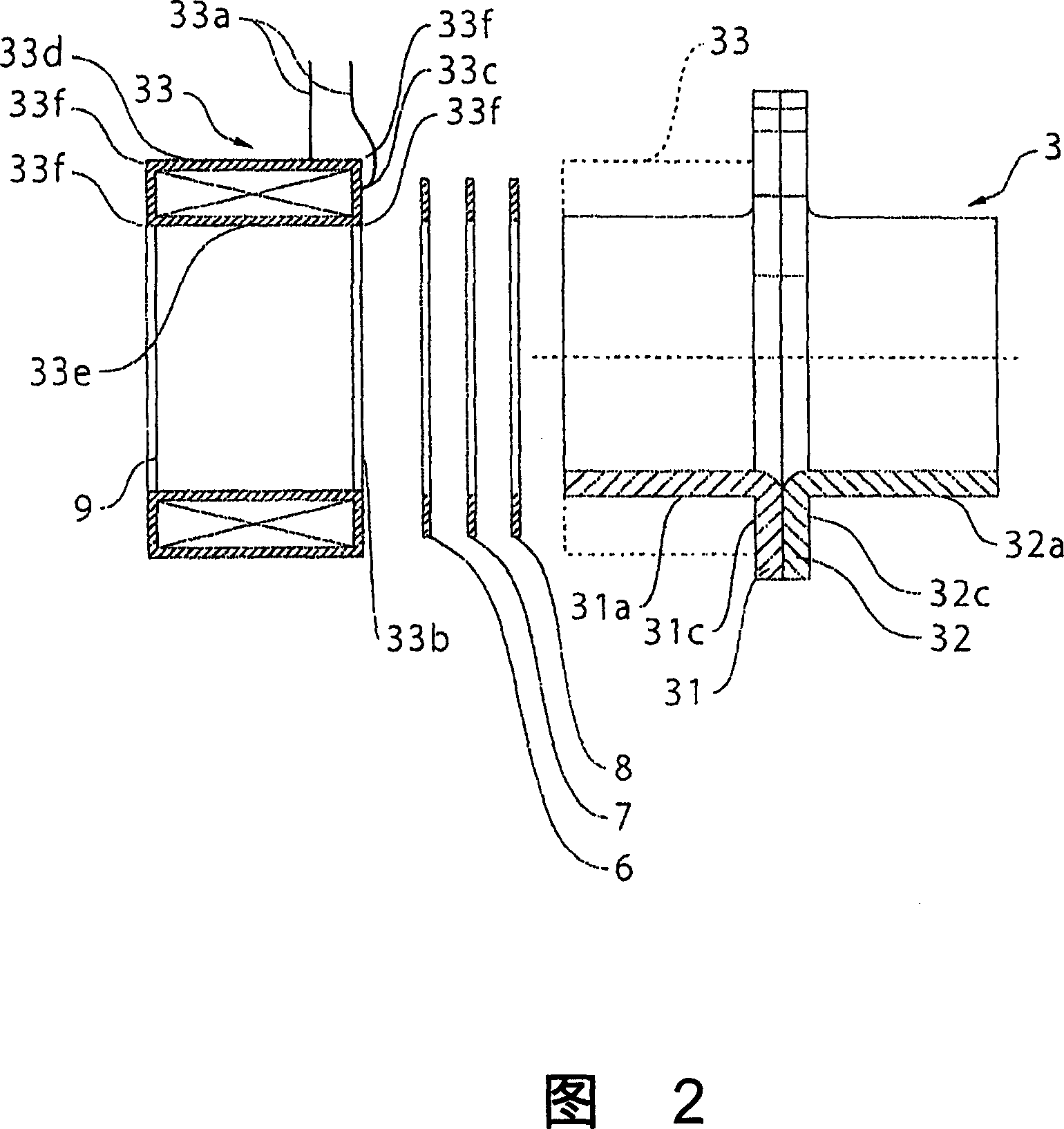

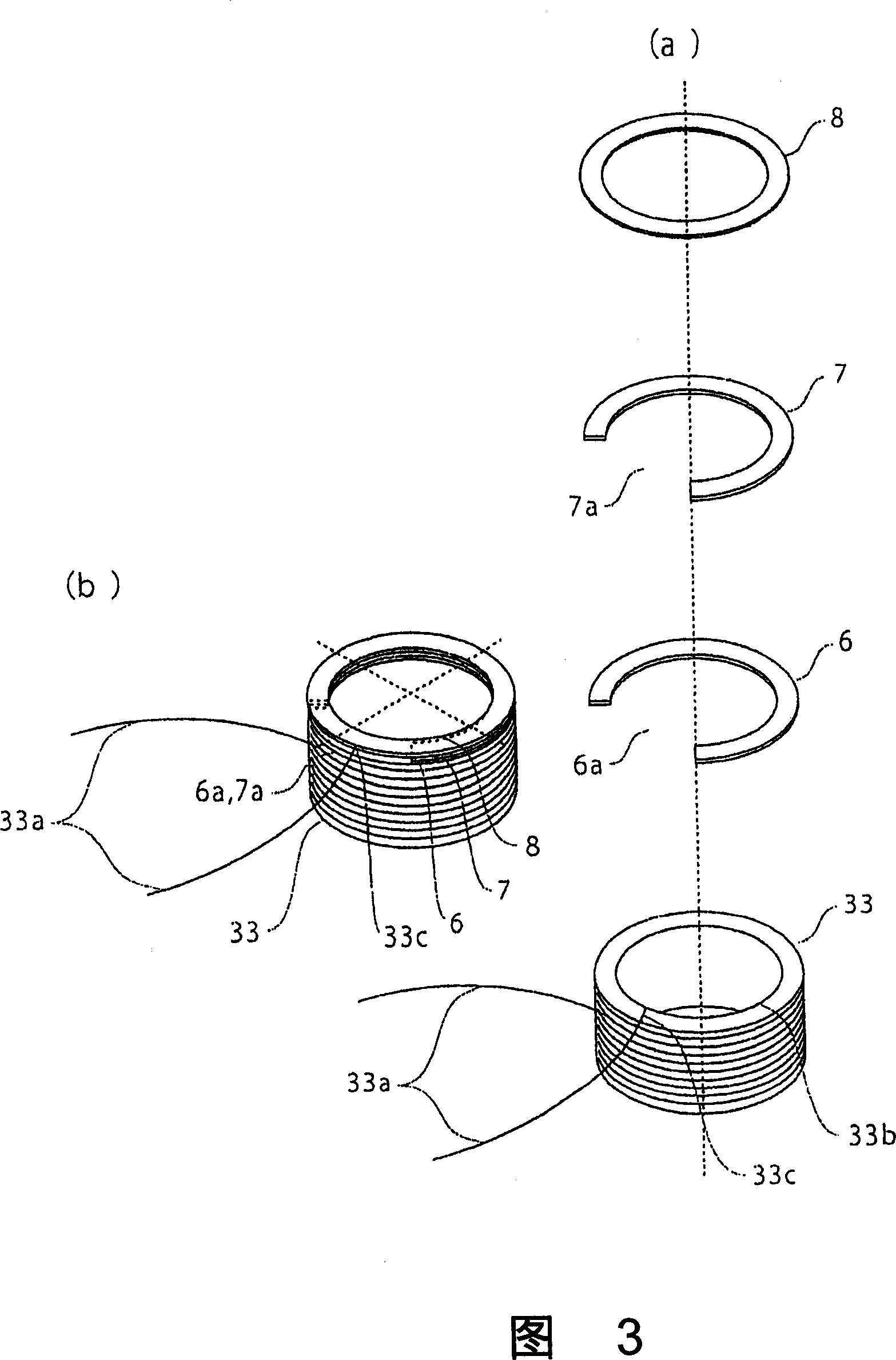

[0063] Fig. 1(a) is a sectional view of a main part of a motor to which the present invention is applied. FIG. 1( b ) is a cross-sectional view showing the structure of a part of the stator of the motor shown in FIG. 1( a ). FIG. 2 is an exploded explanatory diagram illustrating the disassembled structure of the stator of the motor shown in FIG. 1( a ) and FIG. 1( b ). Fig. 3(a) is an exploded perspective view viewed obliquely from above after decomposing the air-core coil, disconnection preventing member, adhesive layer, and insulating sheet in the structure of the stator shown in Fig. 2 . Fig. 3(b) is an assembled view after integrally assembling the air-core coil shown in Fig. 3(a), the disconnection preventing member, the adhesive layer, and the insulating sheet.

[0064] (the overall structure of the motor)

[0065] As shown in Fig. 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com