Press-mounting mechanism for shaft sleeve of rear shock absorber

A shock absorber shaft, press-fitting technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of accumulation and press-fitting of intermediate rubber bodies, affecting product performance and appearance, and deformation, etc., to solve the problems of compression and convenience. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

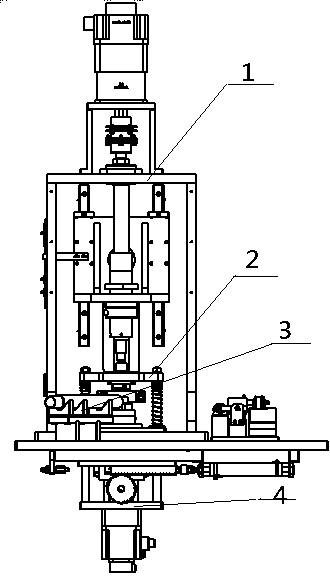

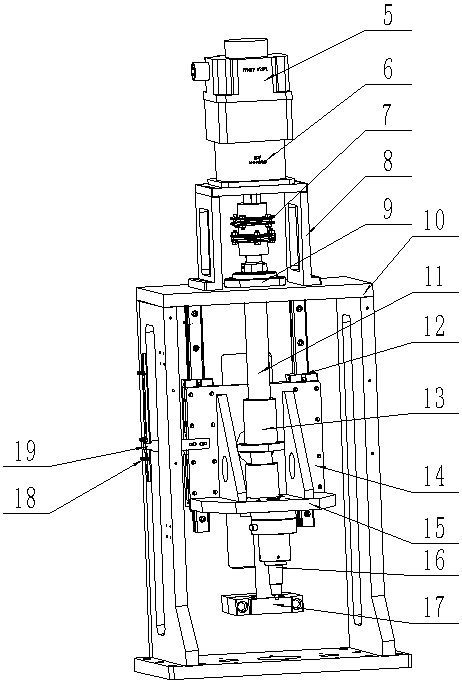

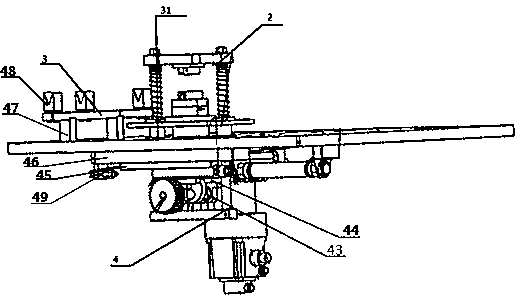

[0023] A rear shock absorber shaft sleeve press-fitting mechanism is characterized in that it includes a servo down-pressing screw mechanism 1, a down-pressing positioning mechanism 2, a lower tooling positioning device 3, a servo back-up screw mechanism 4 and a bottom plate 31. The servo down-pressing screw mechanism 1 includes a down-pressing servo motor 5, a down-pressing reducer 6, a servo motor mounting frame 8, a press-fit mechanism support frame 10, a ball screw 11, a screw nut A13, a pressure head connecting plate 15, Pressing head 16 and screw rod support seat 17, described pressing down servo motor 5 is placed on the upper side of pressing down reducer 6, and described pressing down reducing machine 6 is placed on servo motor mounting frame 8, and described servo motor mounting frame 8 Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com