Protecting component of electronic circuit

A technology for protecting components and electronic circuits, applied in the direction of electrical components, including printed electrical components, printed circuit components, etc., can solve the problems of increasing manufacturing costs and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

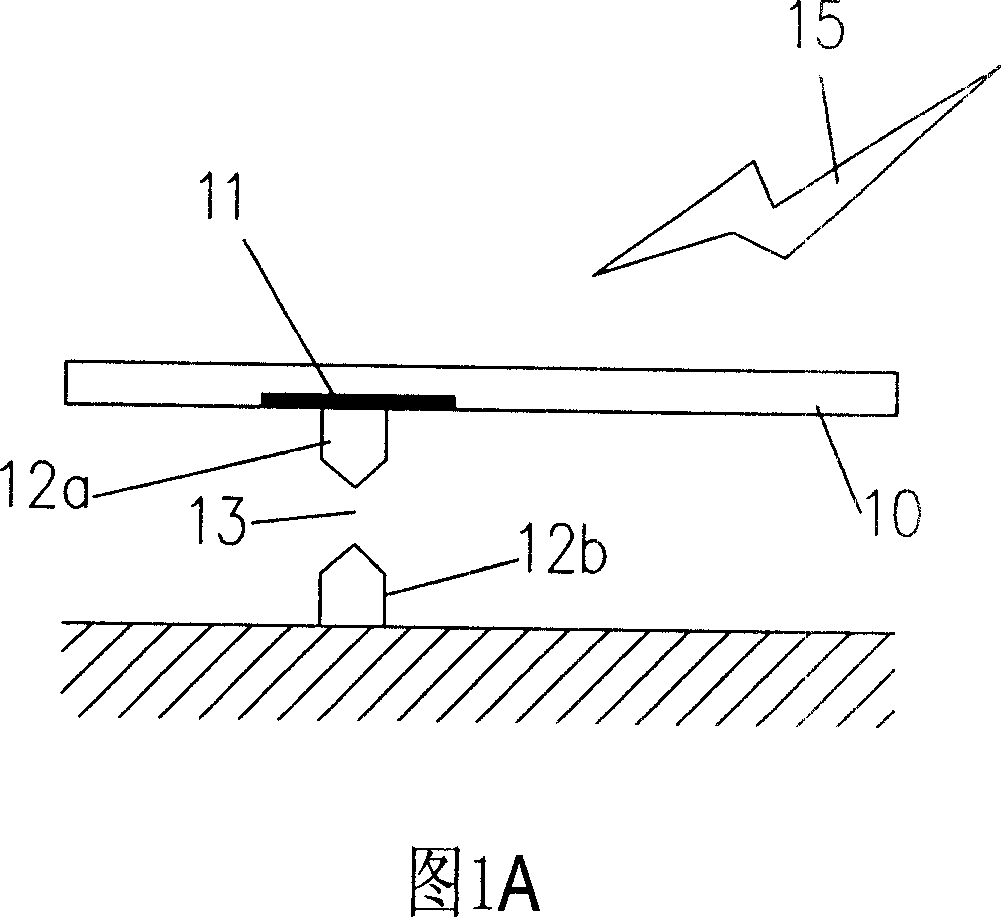

[0029] The detailed composition of the present invention, manufacturing method step, and its effect, function, can obtain further understanding with reference to the explanation that following accompanying drawing is done:

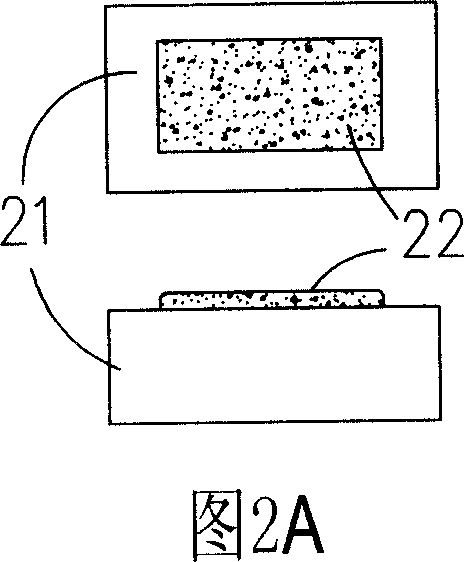

[0030] The protection element of the electronic circuit of the present invention, as shown in Figure 2A-2F, its manufacturing steps are as follows:

[0031] 1. Please refer to FIG. 2A. First, a base glass 22 is made on the upper surface of the ceramic substrate 21. The size of the base glass 22 is controlled in the center of the ceramic substrate 21, so that the side of the base glass 22 does not touch the edge of the ceramic substrate. ;

[0032] 2. As shown in FIG. 2B, the base glass 22 is coated with a first electrode layer 23, one end of the first electrode layer 23 is connected to the first end of the ceramic substrate 21, and the other end of the first electrode layer 23 is partially ground coated onto the upper end surface of the base glass 22;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com