Film layer design method for clearing double layer film structure coated film glass reflection color

A technology of coated glass and design method, which is applied to instruments, optics, optical components, etc., can solve the problems of long cycle, cumbersome testing process, low efficiency, etc., and achieve obvious economic value, reliable calculation results, and shorten the engineering cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the drawings and examples.

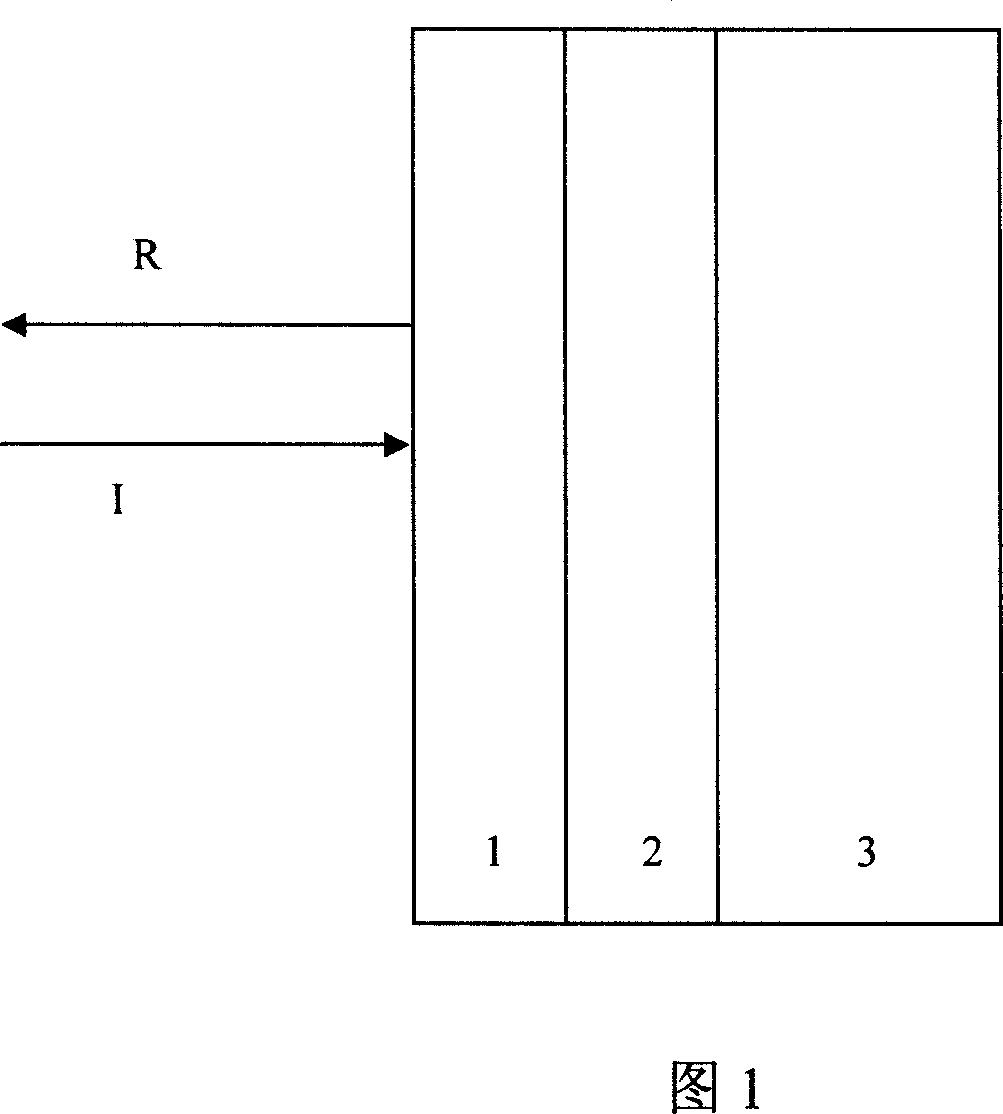

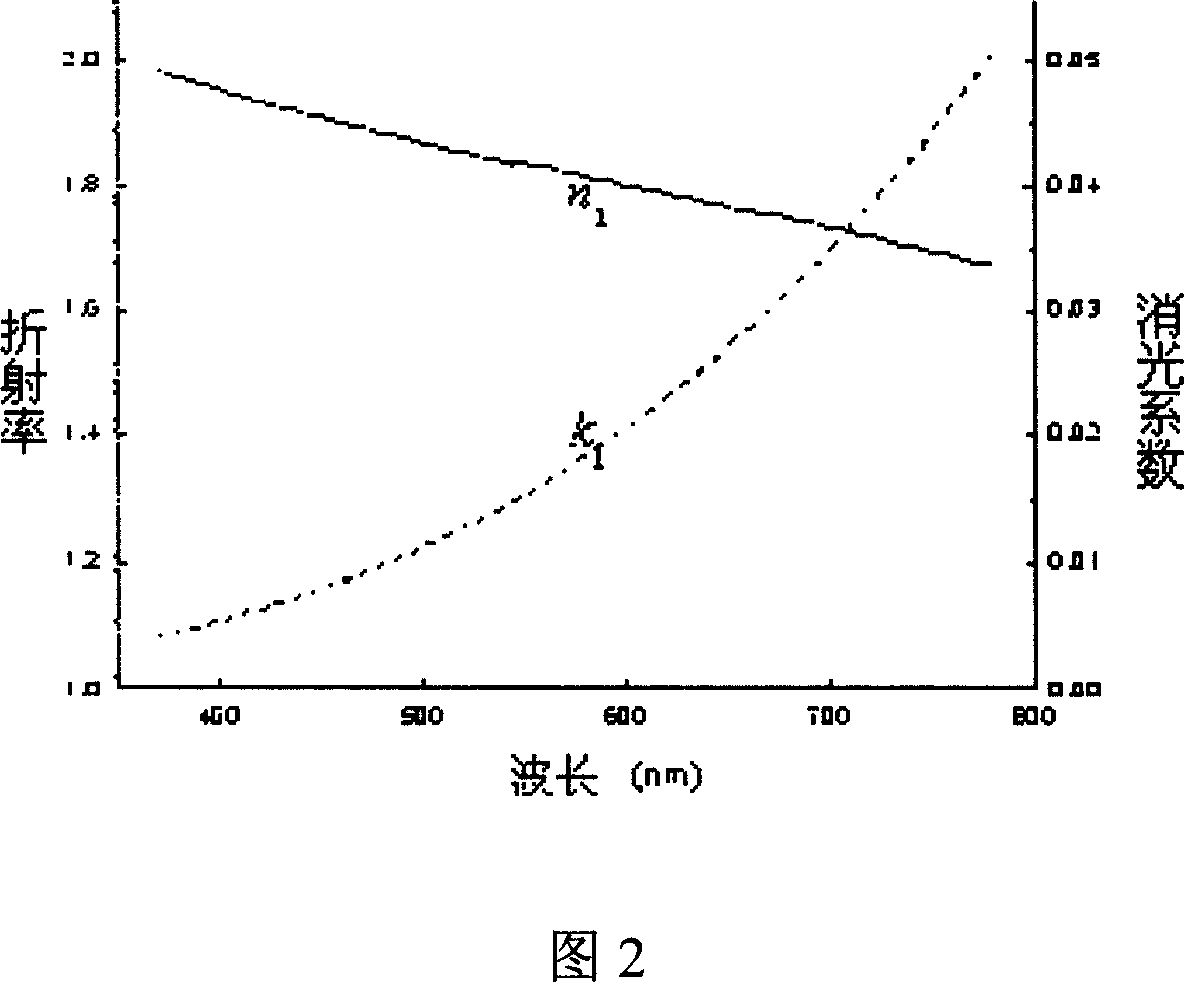

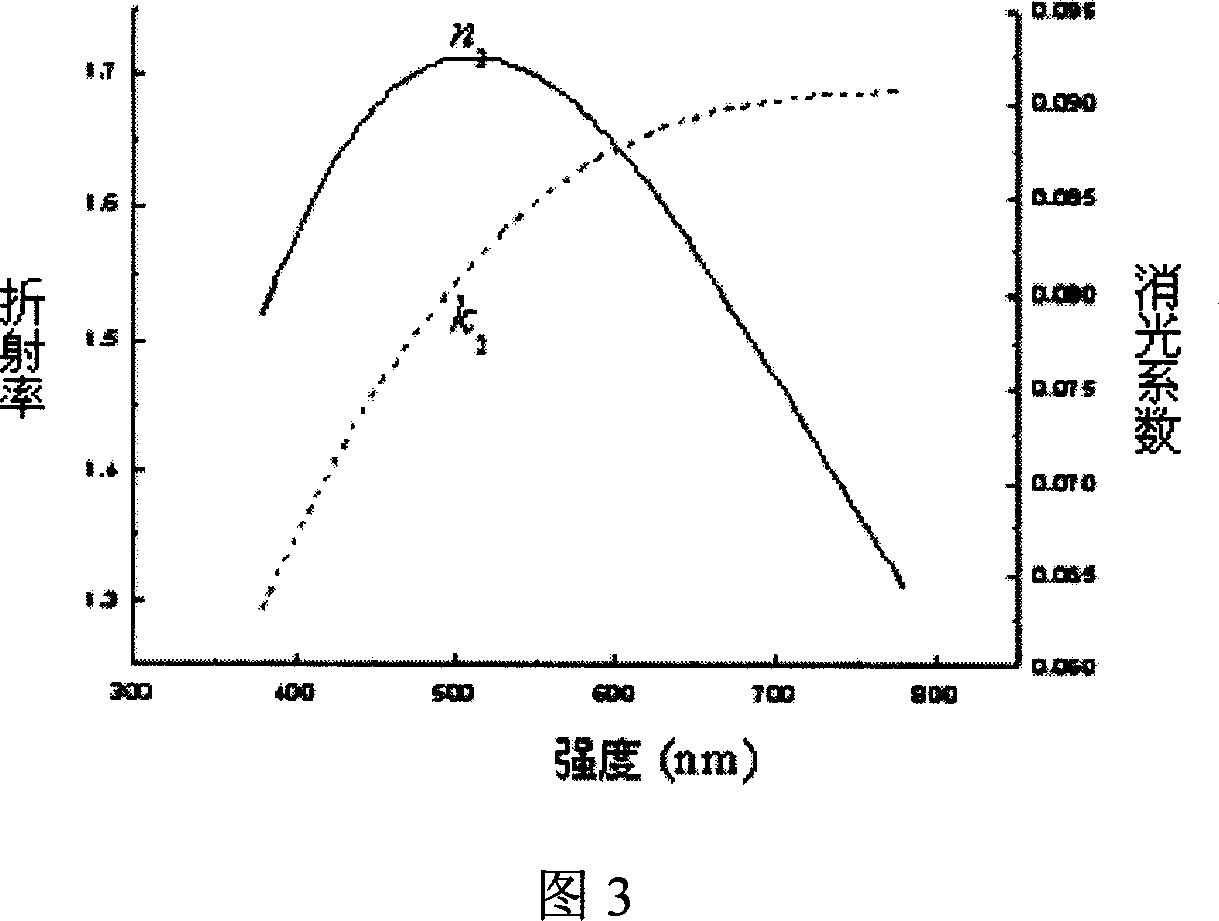

[0019] Taking the coated glass with a double-layer film structure as an example, the film 1 and the film 2 are plated on the ordinary white glass substrate 3 in sequence, as shown in Figure 1, where I and R represent incident light and reflected light respectively. The materials of the two layers are different. The optical parameters of film 1 have been determined, and the refractive index n 1 And extinction coefficient k 1 The curve is shown in Figure 2, the thickness h 1 It is 274.6nm. Thin film 2 is the target layer that needs to be designed to eliminate the reflection color of the coated glass of this double-layer film structure, and its refractive index, extinction coefficient and thickness are respectively denoted as n 2 , K 2 And h 2 , And use a polynomial function with strong adaptability to expand n 2 , K 2 The dispersion relationship with the incident lig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap