Shale gas desorption pressure tester

A desorption pressure and tester technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of inaccurate data, long cycle, low efficiency, etc., achieve reliable data, shorten the project cycle, ensure process and economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

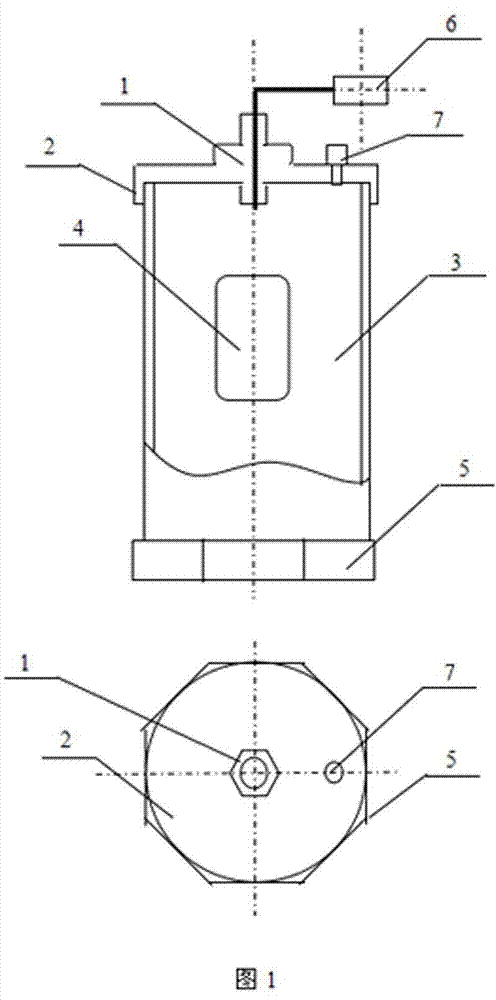

[0014] Add saturated brine that is consistent with the temperature of the formation into the cylinder 3, put the shale core into the cylinder 3, tighten the upper cover 2, and observe from the glass observation window 4 that due to adsorption on the shale surface and micropores A large number of linear bubbles are generated by the desorption and escape of the adsorbed shale gas. The reading of the pressure sensor 7 is the pressure in the cylinder; When the same saturated brine is injected, the pressure value in the cylinder body 3 rises immediately. When it rises to a certain value, the linear bubbles on the surface of the shale core are found to gradually decrease through the observation window 4, and the reading of the pressure sensor 7 at this time is That is the initial desorption pressure of shale gas; with the continuous injection of saturated brine, the pressure in the cylinder 3 continues to increase, and when the linear bubbles on the surface of the shale core are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com