Sequin driving regulating mechanism

A technology of adjusting mechanism and sequins, applied in leno opening mechanism, other opening mechanisms, textiles, etc., can solve the problems of increasing production cost, silk slipping, and factories' reluctance to accept small batch orders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

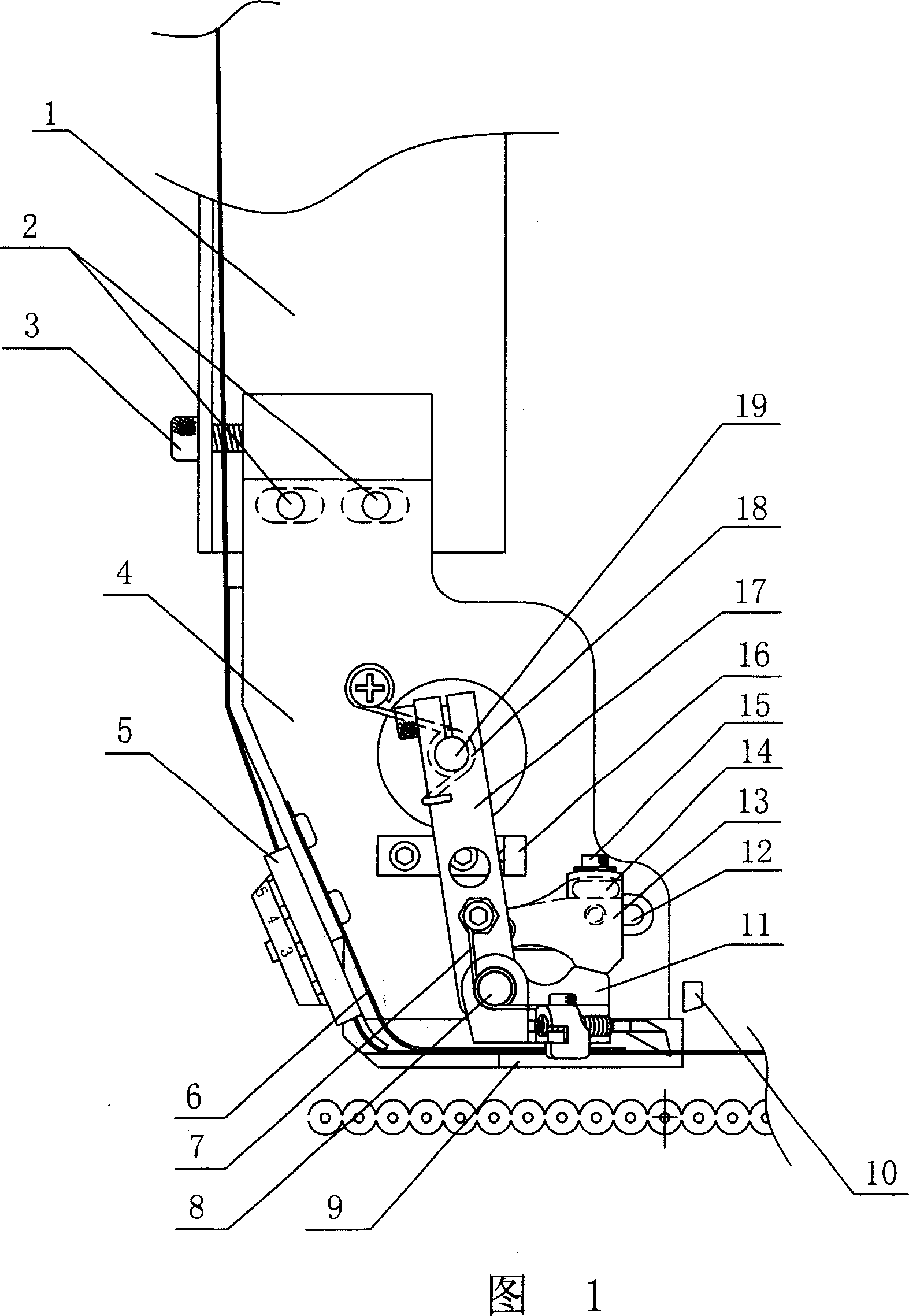

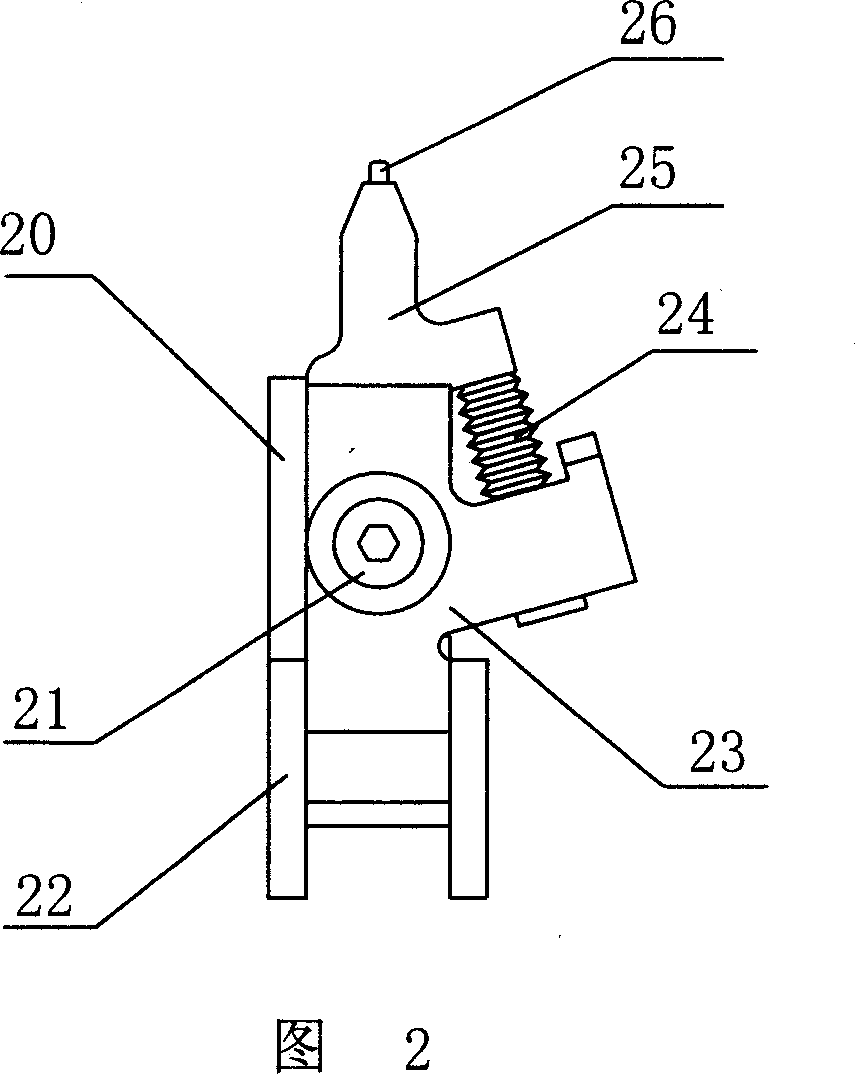

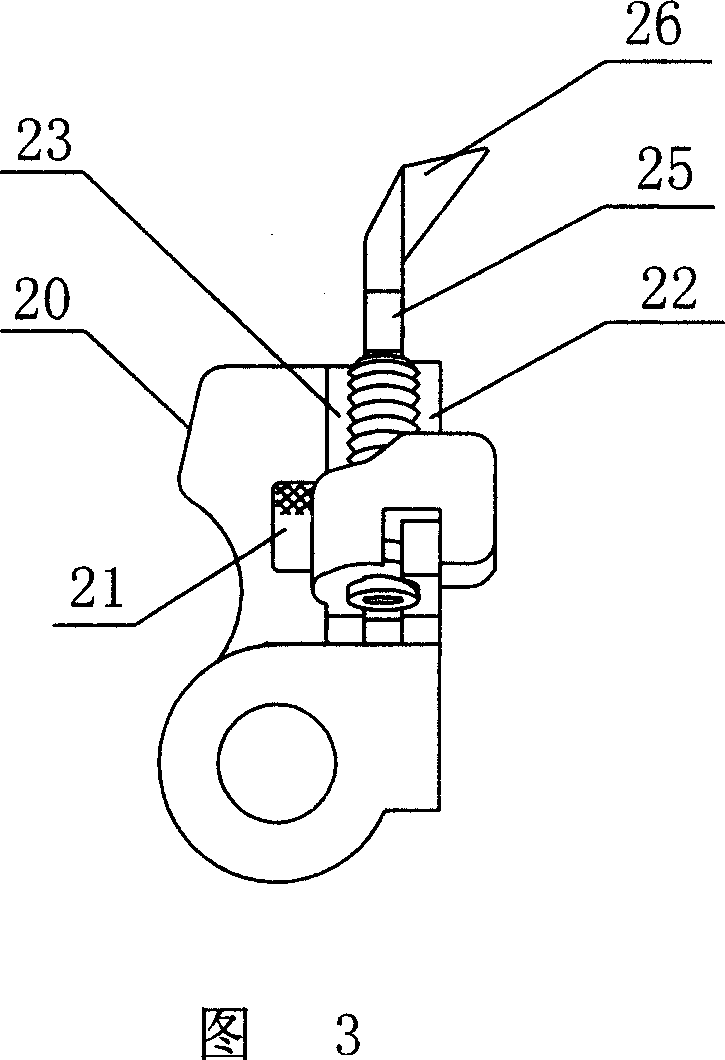

[0017] As shown in the figure, the sequin drive adjustment mechanism includes the sequin frame 4 and the motor connected thereto. The sequin frame 4 is connected with the landing gear 1 through the frame fixing screw 2 and the front and rear adjustment screws 3 of the frame. The upper end of the rod 17 is connected with the motor shaft 19, and elastically cooperates with the bead frame 4 through the return spring 18 of the driving rod, and the lower end of the driving rod 17 is dynamically matched with the front fulcrum device 11 through the connecting shaft 8, and one end of the front fulcrum clip spring 7 is fixed on the dial On the bar 17, the other end elastically cooperates with the front fulcrum device 11, and the corresponding driving lever positioning seat 16 and position adjusting device 13 are set on the sequin frame 4. The driving lever positioning seat 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com