Heat exchangers

一种热交换器、换热管的技术,应用在热交换设备、间接换热器、换热器类型等方向,能够解决加剧、换热管温度分布不均匀、蒸发器难以具有热交换性能等问题,达到热交换效率提高、空气温度均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

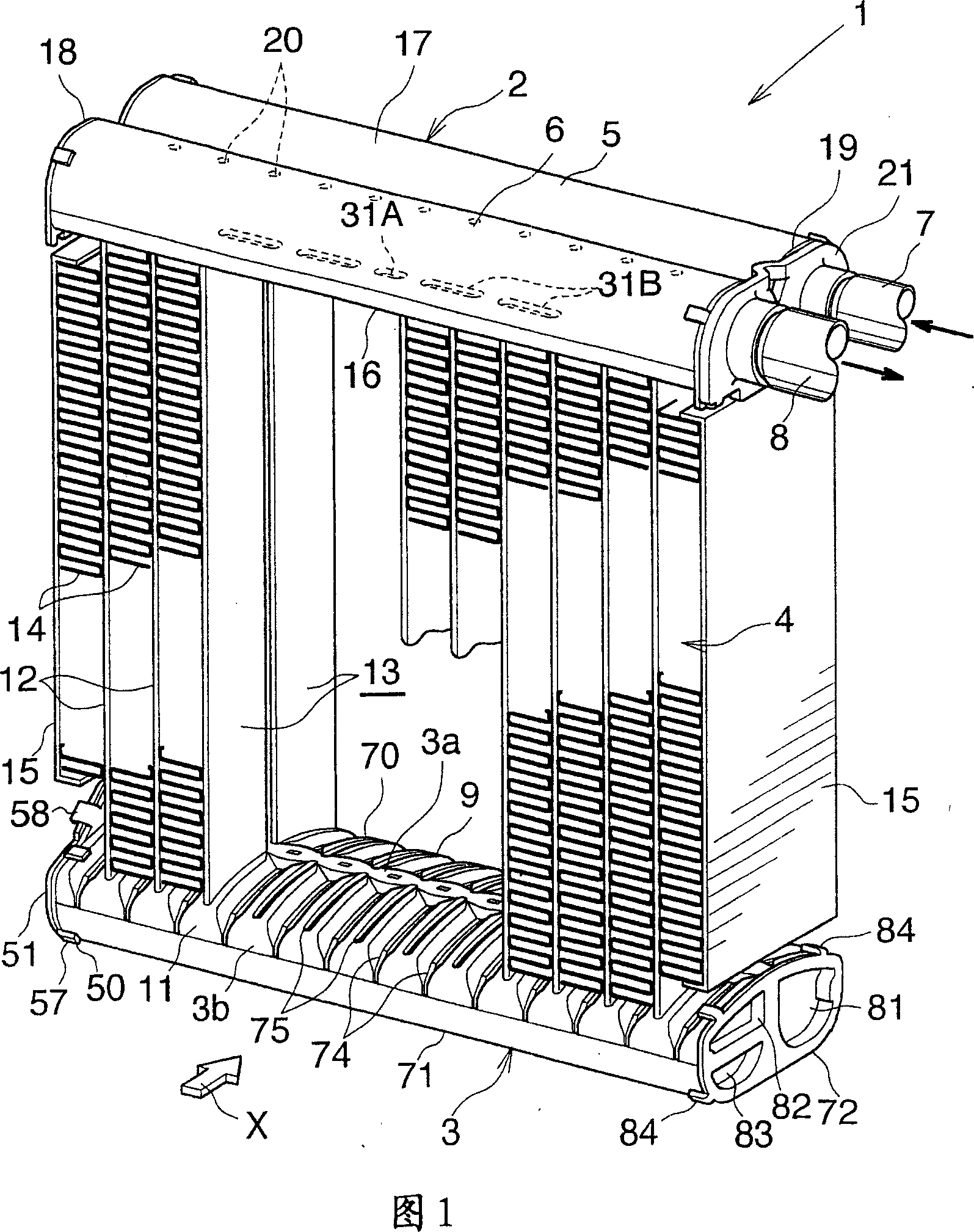

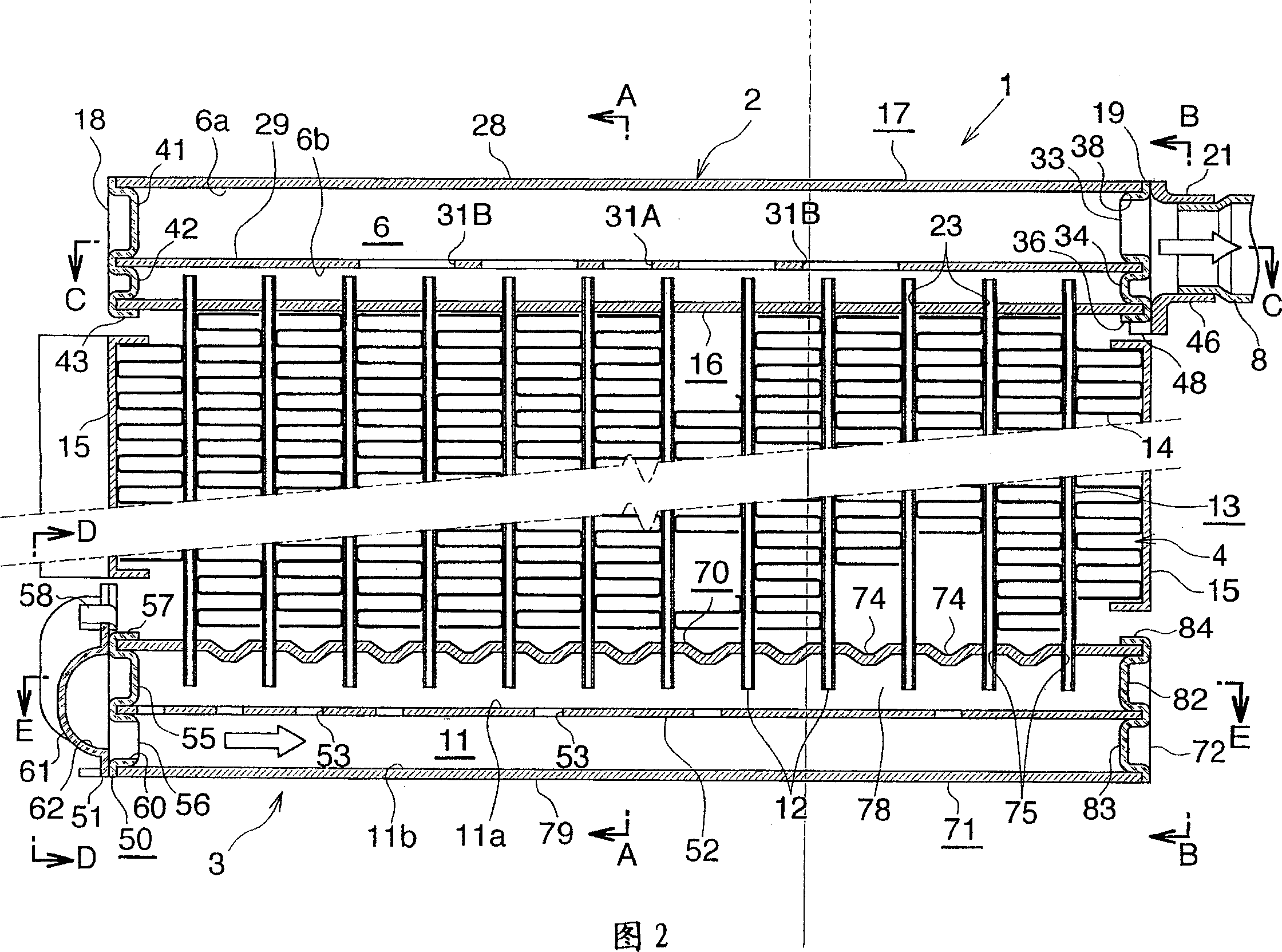

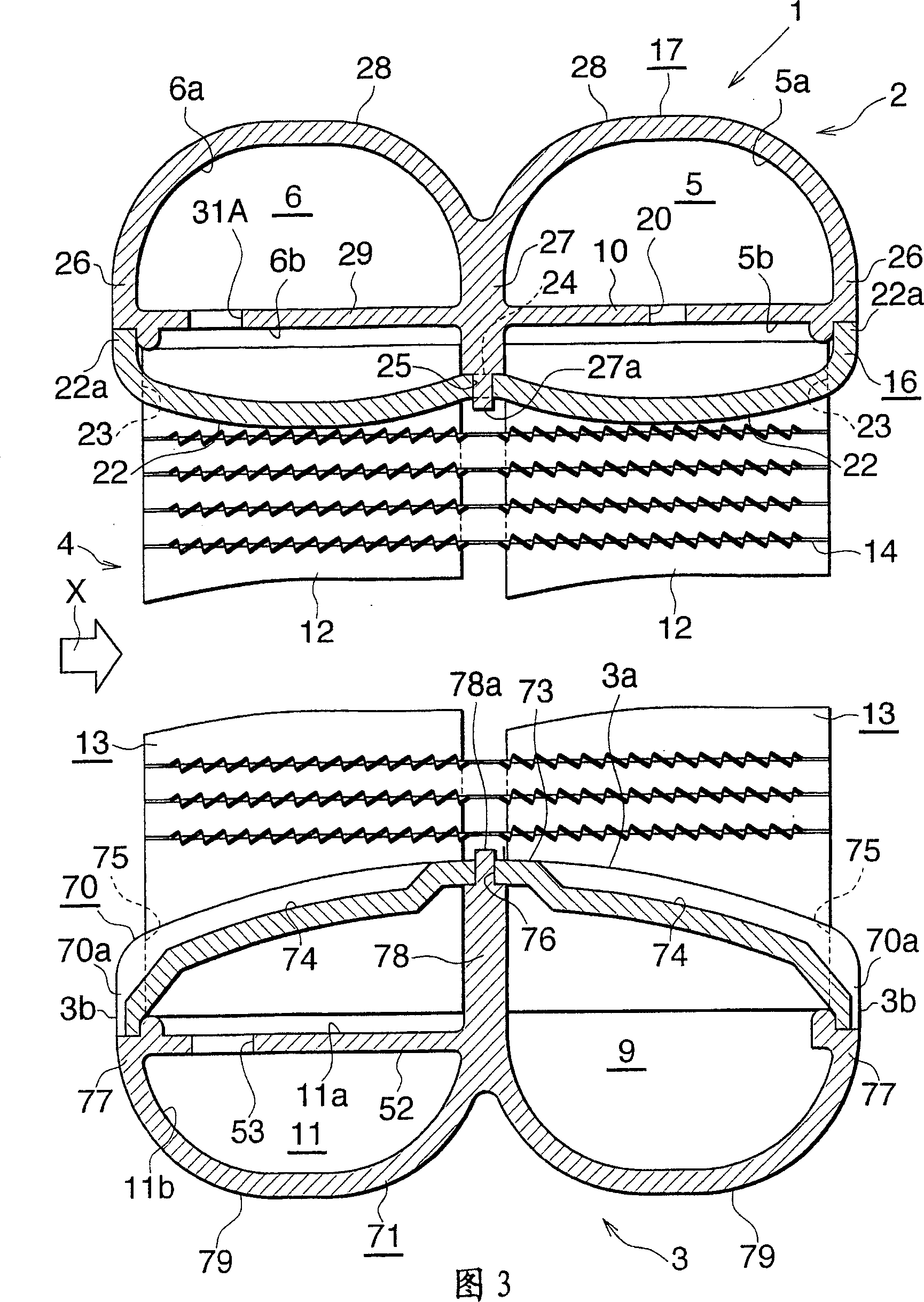

[0065] Embodiments of the present invention will be described below with reference to the drawings.

[0066] In the following description, upper and lower parts and left-hand and right-hand sides of FIGS. 1 and 2 will be referred to as "upper", "lower", "left" and "right", respectively.

[0067] 1 and 2 show the overall structure of an evaporator to which the heat exchanger of the present invention is applied, FIGS. 3 to 10 show the structure of a main part, and FIG. 11 shows how refrigerant flows through the evaporator.

[0068] Figures 1 and 2 show an evaporator 1 comprising an aluminum refrigerant inlet-outlet box 2 and an aluminum refrigerant diversion box 3 arranged up and down at intervals, and an aluminum refrigerant diversion box 3 arranged between the two boxes 2, 3 The heat exchange core 4.

[0069] The refrigerant inlet-outlet box 2 includes a refrigerant inlet header 5 arranged at the front (downstream side with respect to the direction of air flow through the eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com