Drum type washing dryer

A washing-drying machine, drum-type technology, applied in other washing machines, washing machines with containers, washing devices, etc., can solve the problems of strong demand and the steel plate processing method cannot meet the requirements, and achieves easy assembly and improved appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

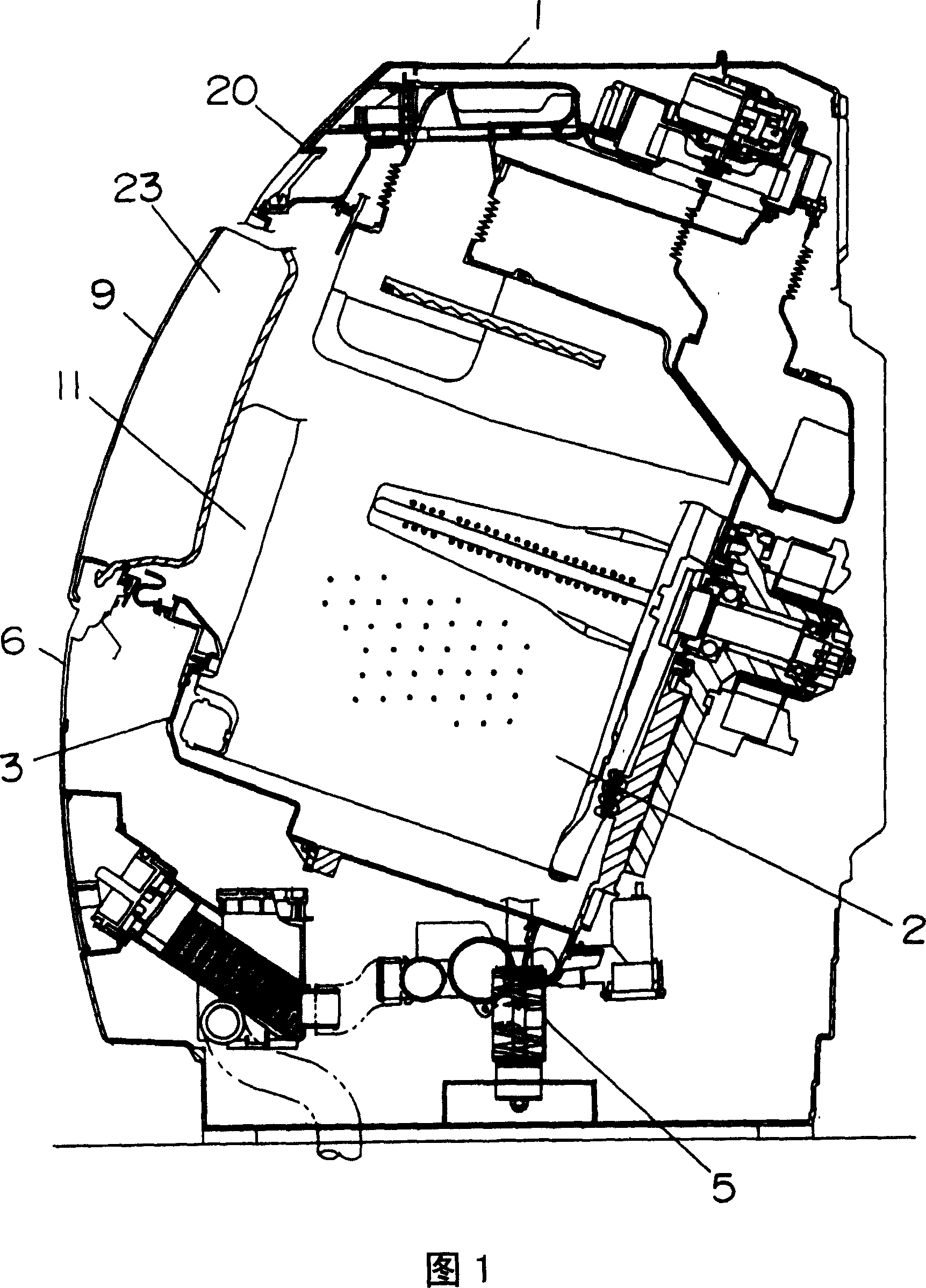

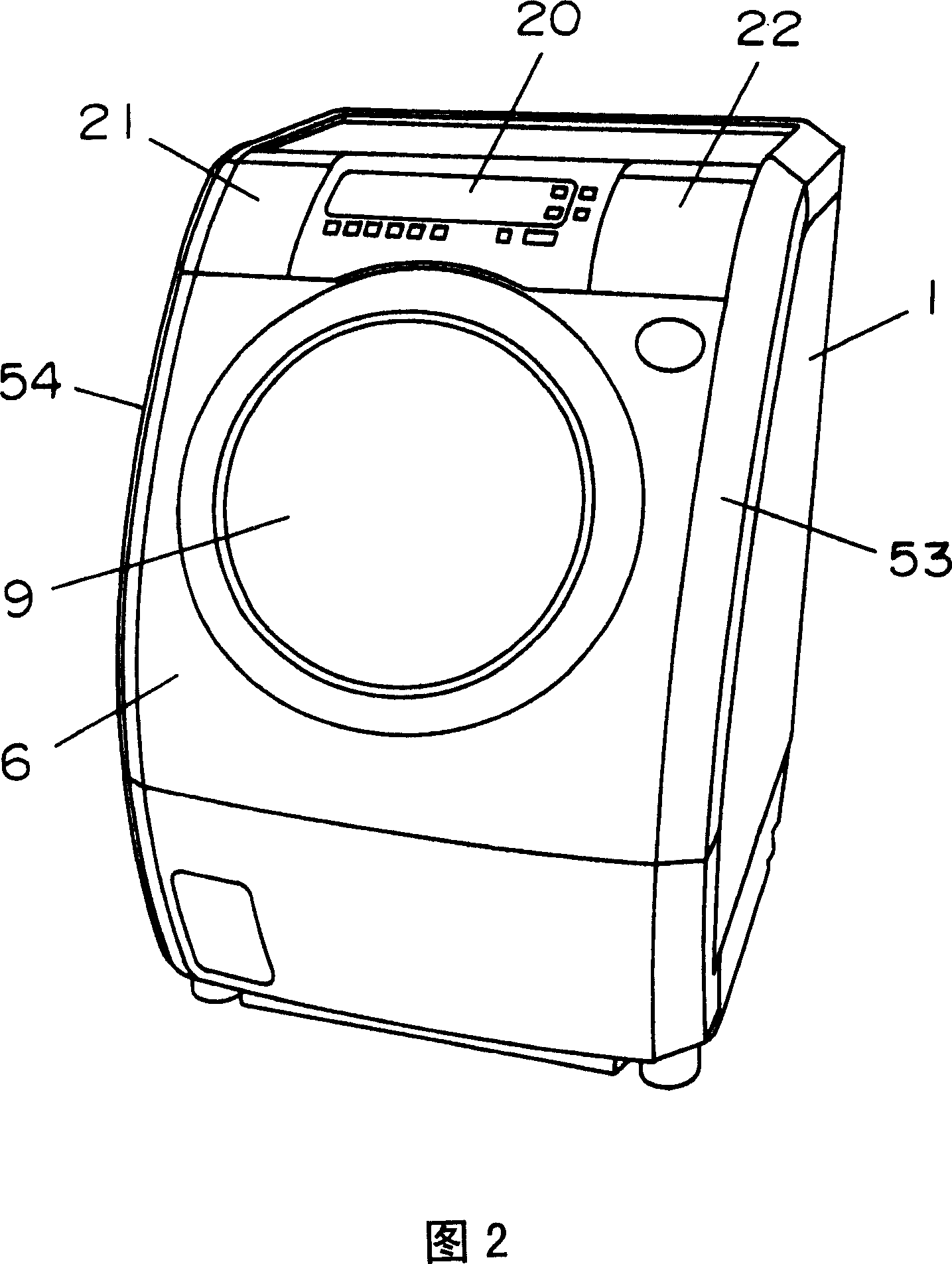

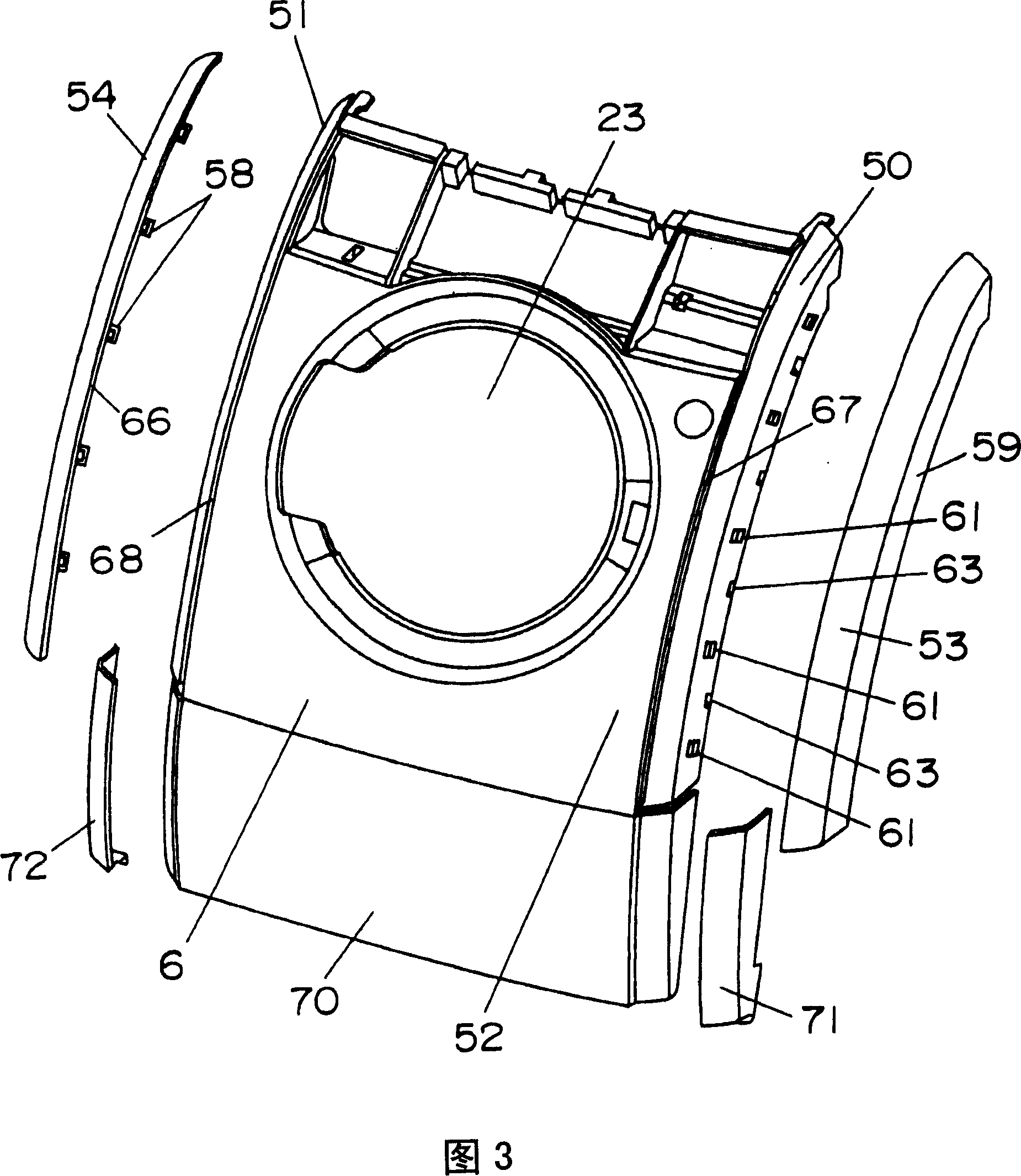

[0028] Fig. 1 is a longitudinal sectional view of a drum-type washer-dryer according to an embodiment of the present invention, Fig. 2 is an external view of the drum-type washer-dryer, and Fig. 3 is a view of the drum-type washer-dryer. Partial exploded oblique view, Fig. 4(a) is a partial sectional view of the first clamping part in the drum-type washer-dryer, and Fig. 4(b) is the third clamping part in the drum-type washer-dryer partial cross-sectional view.

[0029] The composition thereof will be specifically described below with reference to FIGS. 1 , 2 , 3 and 4 .

[0030] As shown in Fig. 1 , the water tub 3 is installed in the body 1 in a vibration-proof manner through a shock absorbing mechanism 5, and a rotating drum 2 in the shape of a bottomed cylinder is provided inside the water tub 3, and the rotating drum 2 The direction of the axis is set to be inclined downward in the direction from the front side to the back side.

[0031] On the front side of the tub 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com