Centrifugal mill for grinding loose material

A loose material, ball mill technology, applied in the direction of grain processing, etc., can solve problems such as unfavorable long time, inability to uniformly grind materials, uneven size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

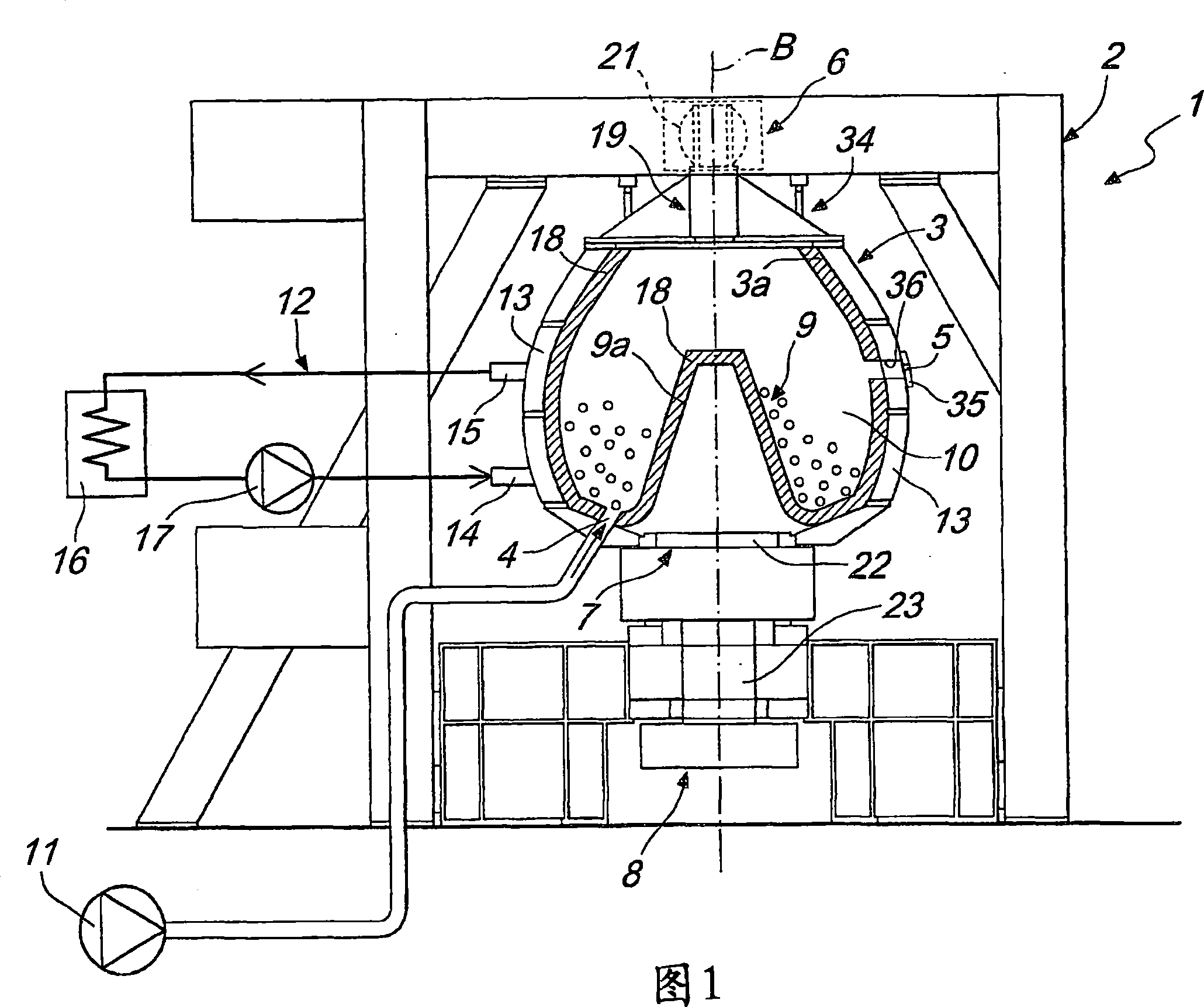

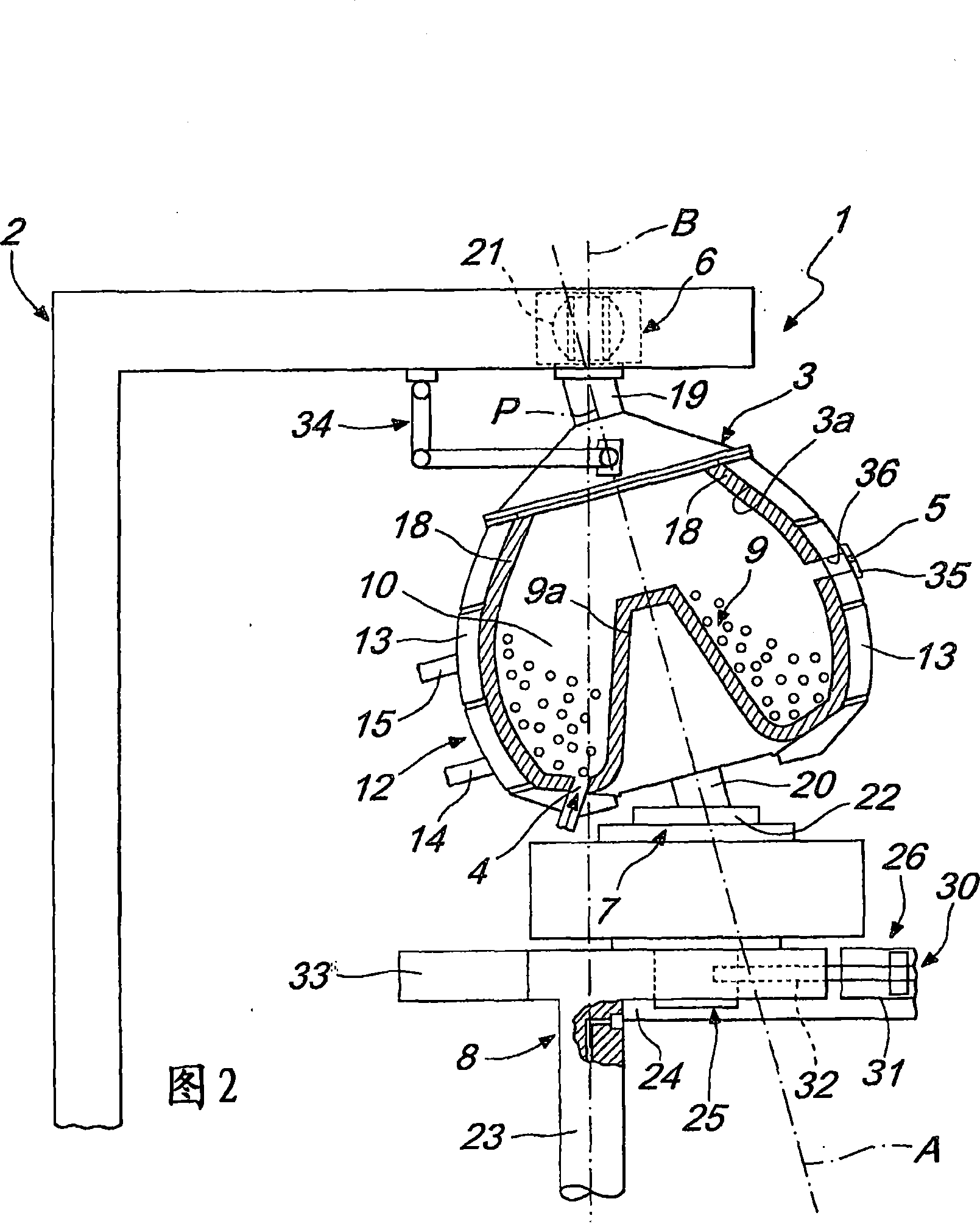

[0023] With reference to the accompanying drawings, reference number 1 generally denotes a centrifugal ball mill for grinding loose materials, especially but not exclusively materials used in the ceramic industry, such as raw materials for mixtures, enamels, screen printing pastes, etc. .

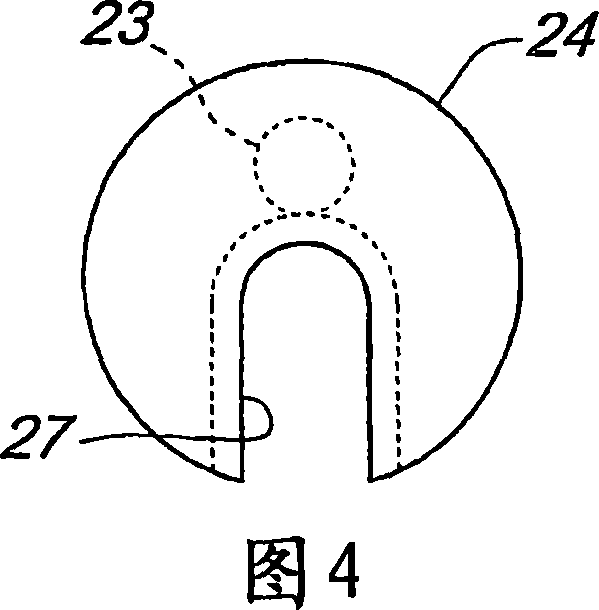

[0024] The ball mill 1 comprises a fixed support frame 2 for supporting a grinding chamber 3 provided with a convenient axis of symmetry, the longitudinal axis A, and provided with at least one opening 4 for the introduction of the material to be ground and for the discharge of the ground material. The opening of the material 5.

[0025] First means 6 for articulating the chamber 3 to the frame 2 are constituted at one of the two opposite ends close to the longitudinal axis A and are adapted to enable the movement of the chamber 3 so that the longitudinal axis A is around a fixed axis at a common point of entry P B turns. The angle of entry between the two axes A and B remains substantial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com