Technique for processing organic green tea

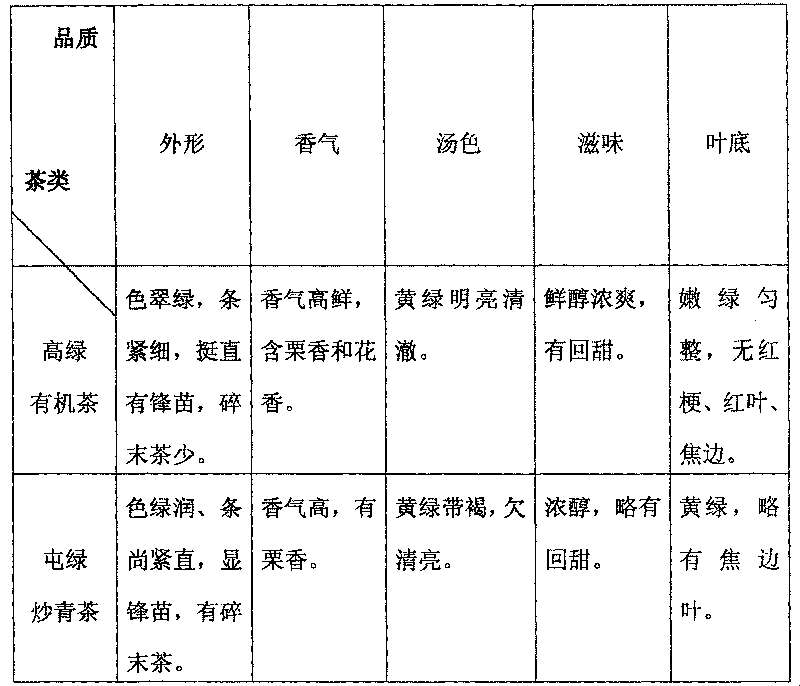

A processing technology, a technology for green tea leaves, which is applied to the processing technology field of agricultural products, can solve the problems of dull color, brownish yellow soup color, scorched leaf bottom, etc., and achieves the effect of emerald green color and yellowish green soup color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: When the new shoots of the tea trees in the organic tea garden grow to one bud and one leaf, they can be mined, and the fresh leaves are packed in clean bamboo baskets, and they are not squeezed and sent to the plant in time to be cooled with a bamboo mat to spread the thickness of the leaves 2-3 cm, blow it in summer, let it cool for 50-60 minutes, and turn it lightly once every 20 minutes. Choose the 6CH-70 fresh-leaf bamboo classifier, classify according to the large and small leaves, and classify and finish. Use the 6CH-30 type drum fixer to fix the greens, the temperature is 170°C-180°C, and the time is 3-5 minutes. The green leaves are immediately placed on a bamboo mat and spread out for about 20 minutes, and then kneaded with a 6CH-35 kneading machine for 10-15 minutes. Pressurization method: light pressure for 2-3 minutes, heavy pressure for 4-5 minutes, loose pressure for 4-5 minutes. Knead the leaves and spread them thinly for 5-8 minutes befo...

Embodiment 2

[0025] Embodiment 2: pick from the buds and leaves in the organic tea garden, pick the standard one bud, two and three leaves, put the fresh leaves in a ventilated bamboo basket or cloth bag, do not squeeze them, and spread them thinly for 70-70-5 centimeters before sending them to the factory for processing. 80 minutes, lightly turn once every 20-25 minutes. Use a 6CH-30 or 6CH-50 roller degreening machine for degreening. The temperature is 170°C-180°C and the time is 4-5 minutes. After 15 minutes, knead with a 6CH-45 kneading machine for 25-30 minutes, pressurize lightly for 8-10 minutes, pressurize for 10-15 minutes, and loosen for 5-8 minutes. After a little thinning, use a wooden deblocking machine for deblocking and initial drying, using a 6CH-20 automatic dryer for initial drying, at a temperature of 130°C-140°C, for about 8-10 minutes, and a water loss rate of about 42%. After the first-dried leaves are spread on bamboo mat for 10-15 minutes, roll the second green with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com