Light guidance plate

A light guide plate and light incident surface technology, applied in the field of light guide plates, can solve the problems of uneven light, easy to generate light beams, halos and dark bands, and uneven light output brightness of the light guide plate, so as to achieve the best light splitting effect and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

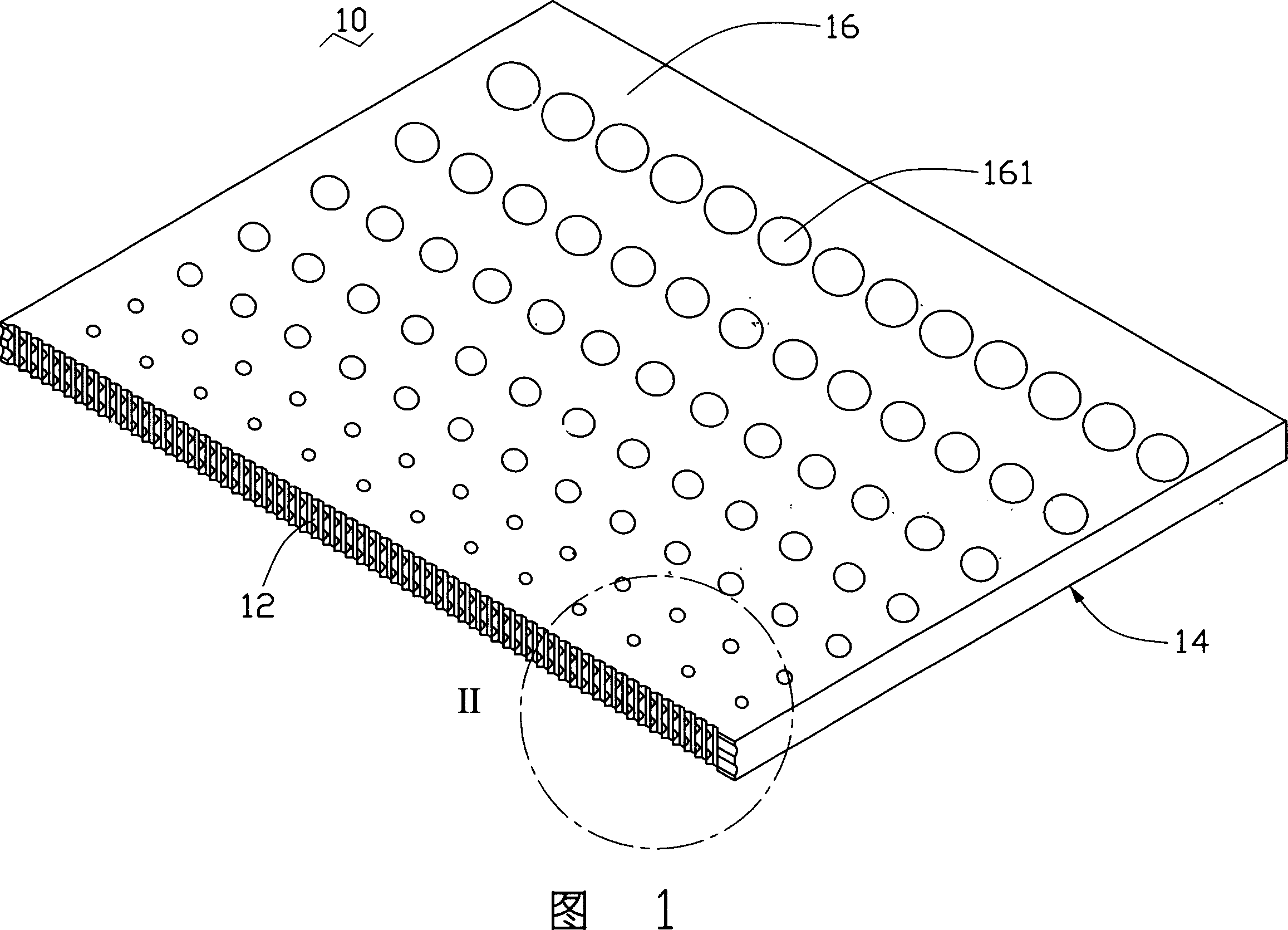

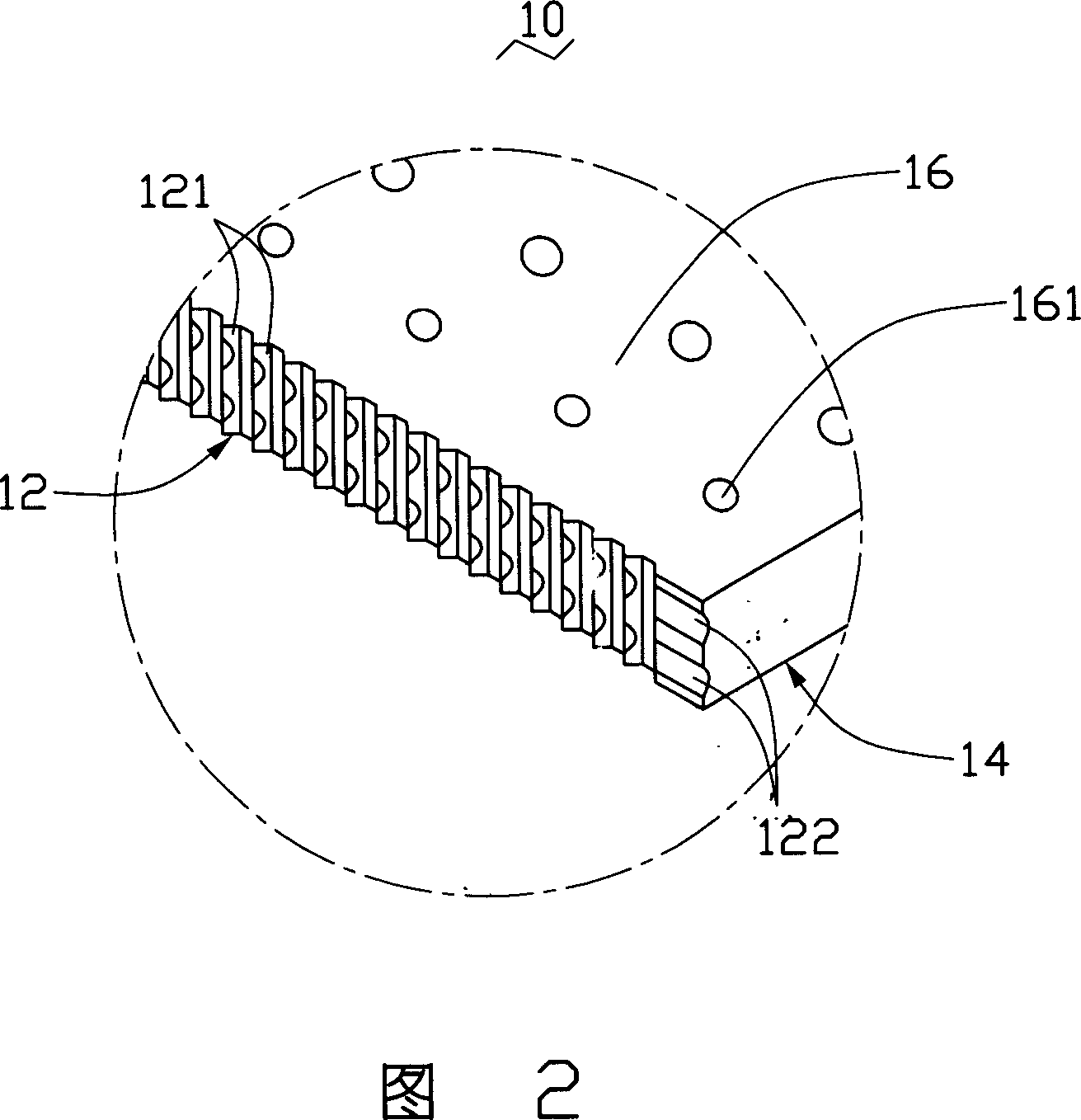

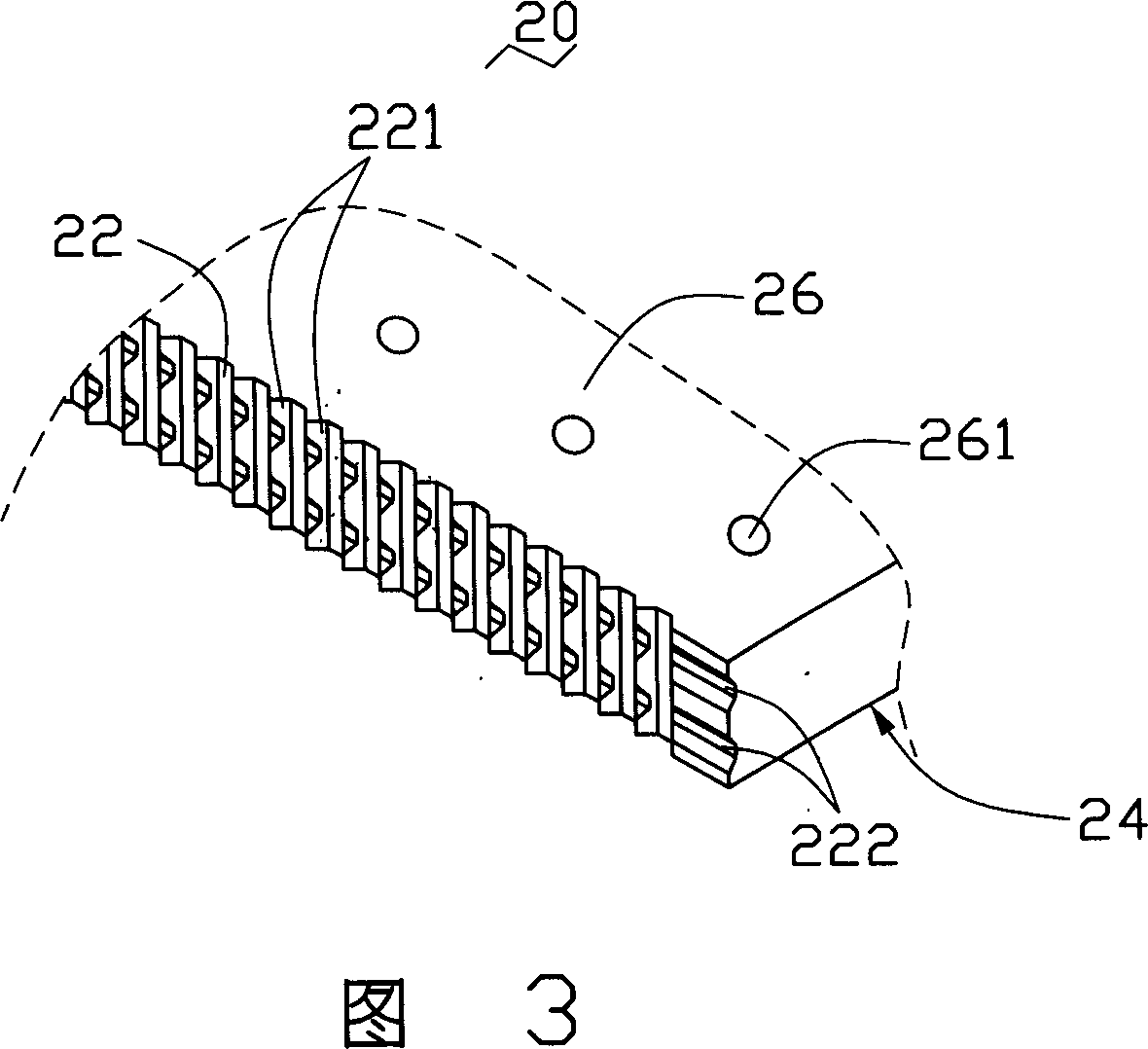

[0011] Please refer to Fig. 1 and Fig. 2, which are the light guide plate 10 provided by the first embodiment of the present invention, the light guide plate 10 includes a light incident surface 12, a light exit surface 14 connected to the light incident surface 12 and a Bottom 16.

[0012] The light guide plate 10 is flat. External light enters the light guide plate 10 through the light incident surface 12 , is reflected by the bottom surface 16 , and passes through the light exit surface 14 .

[0013] The light incident surface 12 is provided with a plurality of first groove-shaped microstructures 121 and a plurality of second groove-shaped microstructures 122, wherein the extension direction of the first groove-shaped microstructures 121 is perpendicular to the light-emitting surface 14, and the second groove-shaped microstructures The extension direction of the microstructure 122 is parallel to the light-emitting surface 14, that is, the first groove-shaped microstructure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com