Method for setting up optimized width of rough rolling strip steel

An optimized setting and strip steel technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as excessive width margin, unstable production process, and large randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] In order to understand the content of the present invention more clearly, the following will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

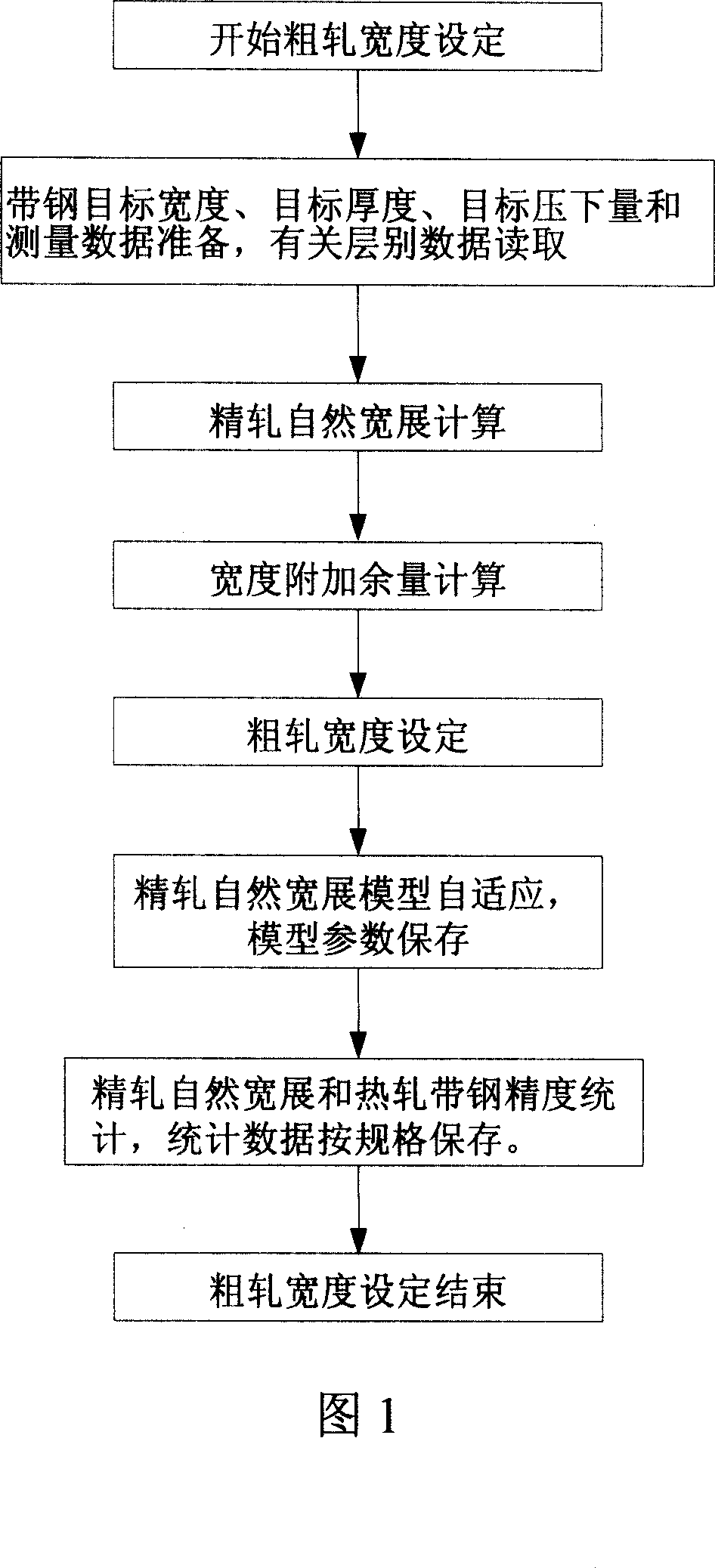

[0104] Please refer to Figure 1 to start rough rolling width setting, first read the target width, target thickness, and target reduction of the strip to be rolled from the layer data table, and read the previously rolled strip the actual natural width of the strip; read the specification data and model adaptive data of the current strip; calculate the natural width of the current strip; Statistical accuracy of width control of standard strip steel, calculated according to the statistical accuracy to calculate the additional margin of the strip width; according to the calculated natural width of the finishing rolling, the additional margin of the current strip width, the target width of finishing rolling and manual correction by the operator value, determine the rough rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com