Method and apparatus for warming-up and starting up luminous tube

A starting device and lamp technology, applied in lighting devices, light sources, electrical components, etc., can solve the problems of different starting time and unclear preheating time, and achieve the effects of simplified components, accurate preheating and starting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

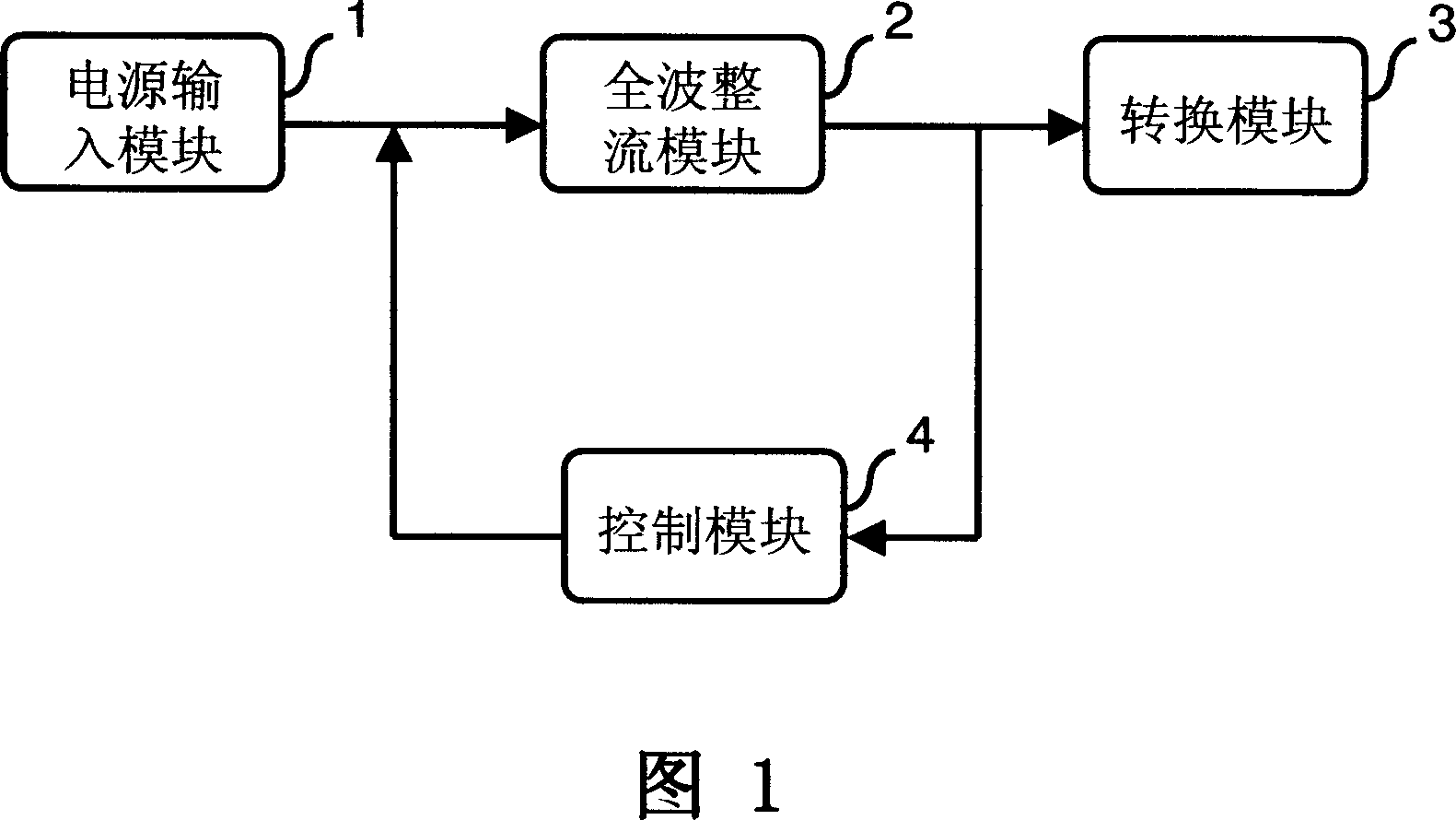

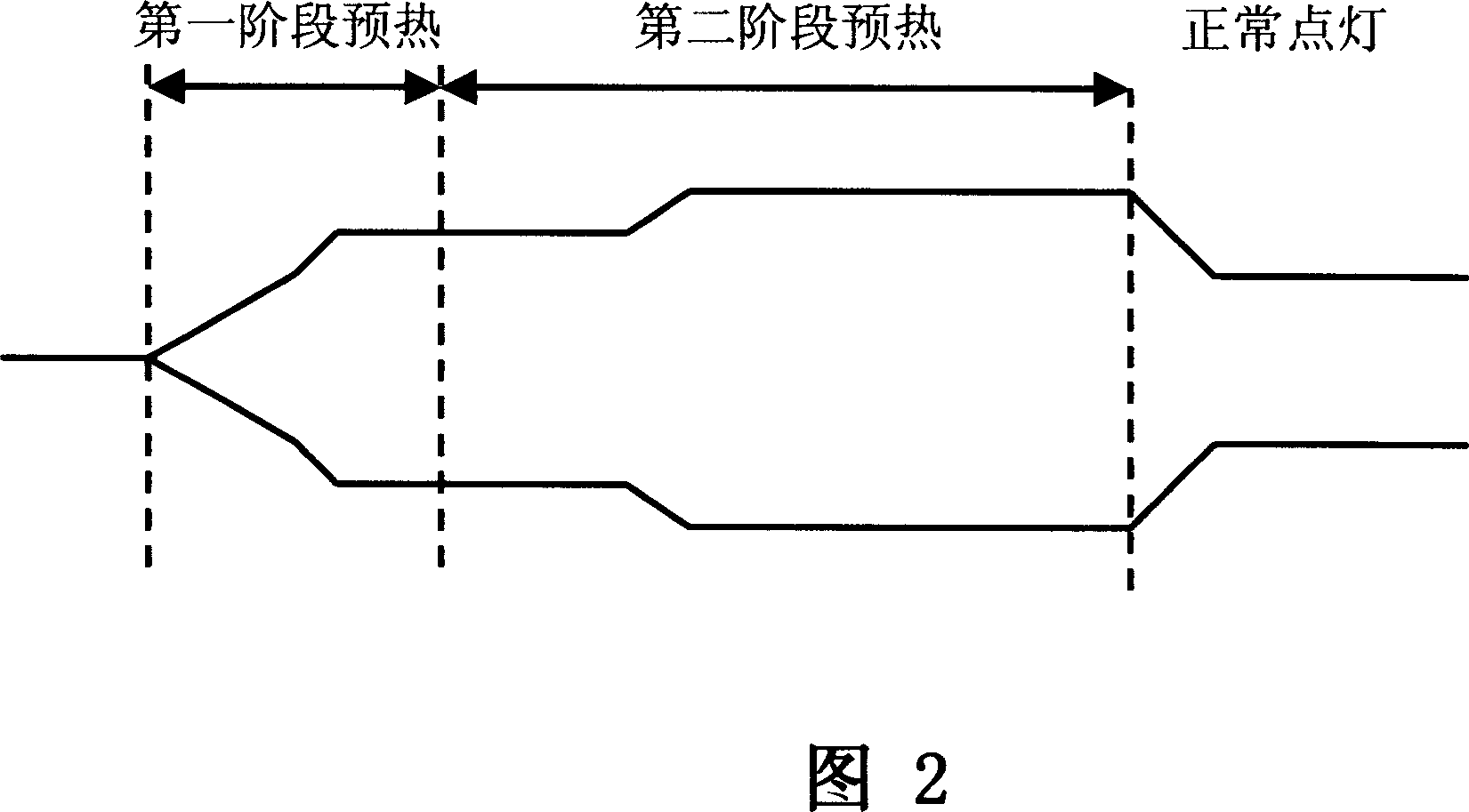

[0067] The present invention is an electronic ballast for lighting a lamp tube. The lamp filament is preheated by a frequency conversion preheating mode and then the lamp tube is started. As shown in FIG. 2, it is a waveform diagram of the filament preheating disclosed in the present invention. , The lamp is turned on after the first preheating time and the second preheating time in the frequency conversion preheating method, so the preheating time can be accurately grasped, and the start time of each time will not be different due to the aging of the electronic parts. The preheating method disclosed in the present invention realizes frequency conversion by means of electronic circuits and software, adopts flexible starting of the lamp tube, can achieve the purpose of using on lamp tubes of different starting forms and effectively extending the life of the lamp tube.

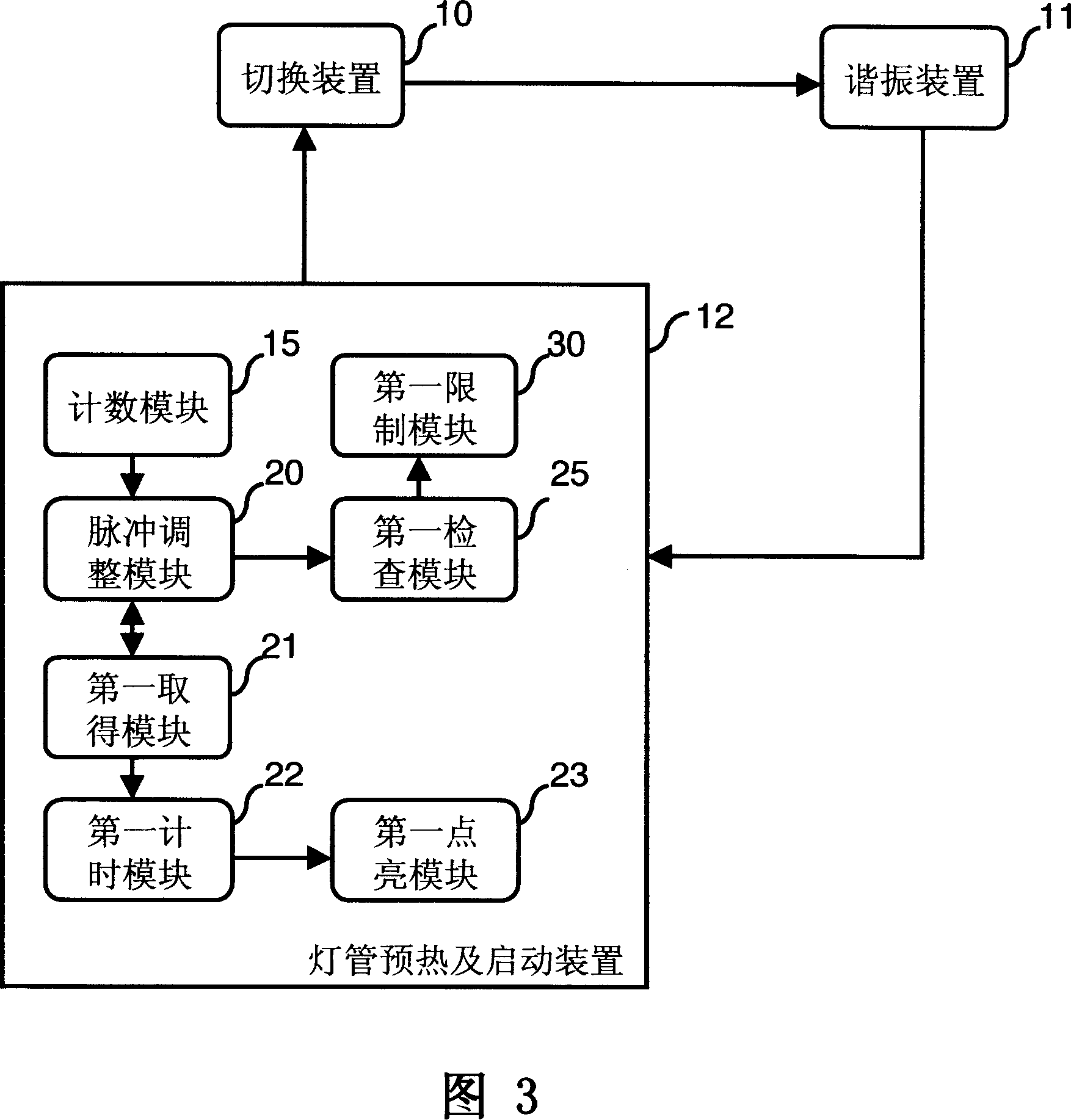

[0068] Please refer to FIG. 3, which is a block diagram of the first lamp preheating and starting device 12 discl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com