Small-sized industrial boiler hearth

A technology for industrial boilers and furnaces, which is applied to combustion methods, combustion chambers, casings/linings, etc., can solve problems such as insufficient combustion of gas and solid-phase carbon, burning of embers, high water cooling in the furnace, and coal not easily ignited. To achieve the effect of good sealing, large boiler output and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

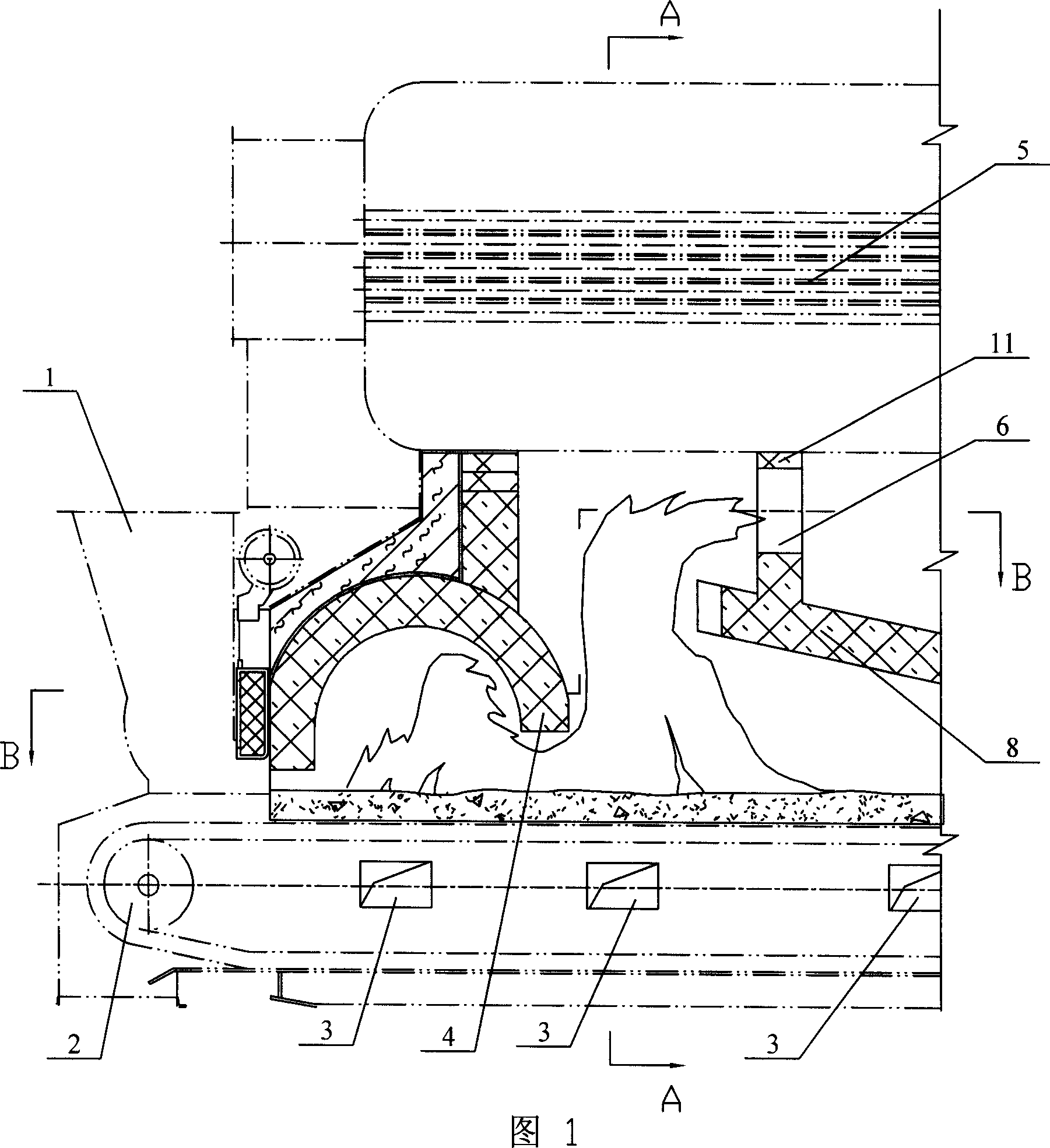

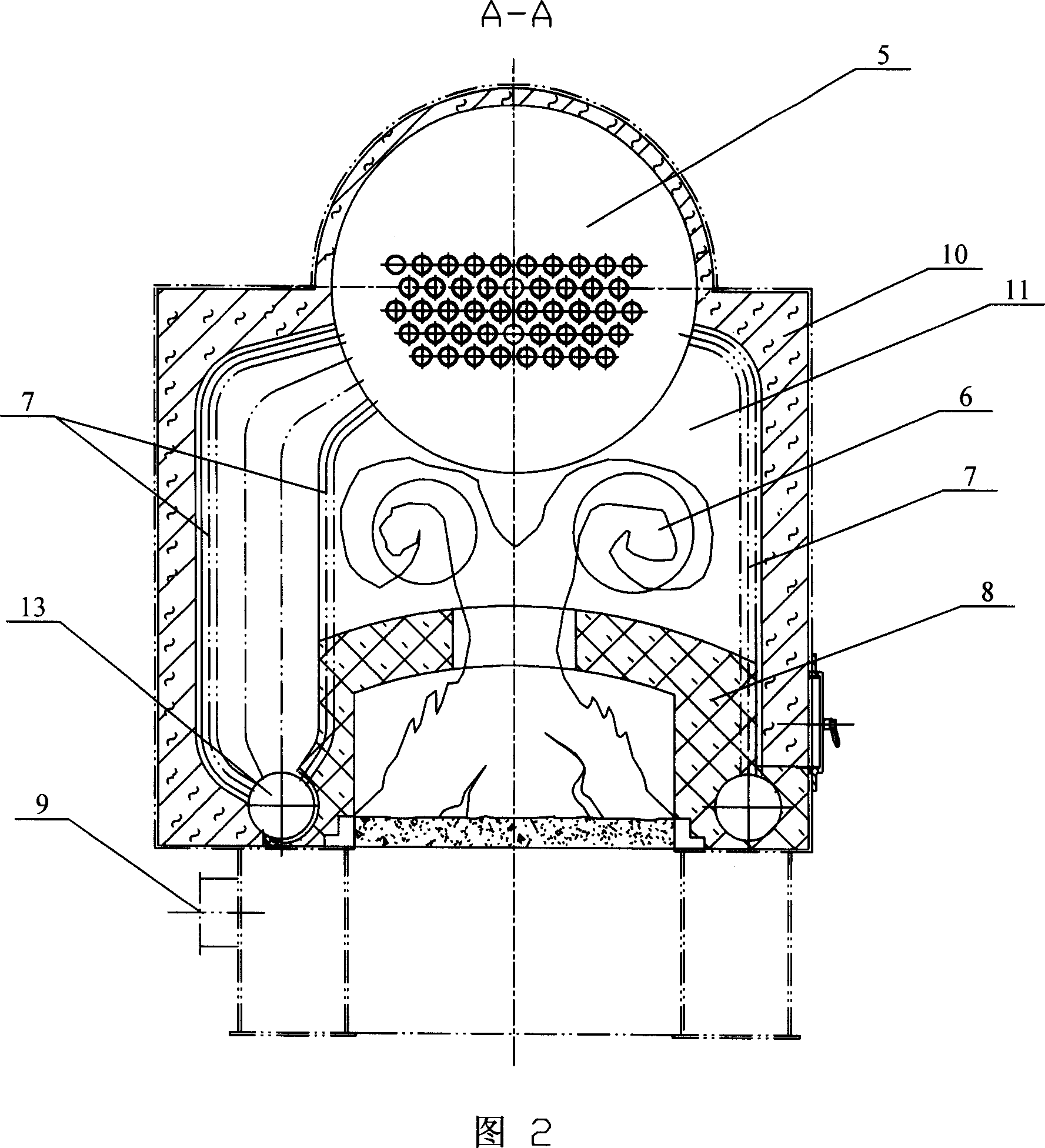

[0007] Specific Embodiment 1: This embodiment will be described in conjunction with FIG. 1 , FIG. 2 , and FIG. 3 . Present embodiment it is made up of back arch 8, furnace wall 10 and semicircle front arch 4, and semicircle front arch 4 is located at the left side of furnace, and the left side arch of semicircle front arch 4 is lower than the right side arch.

specific Embodiment approach 2

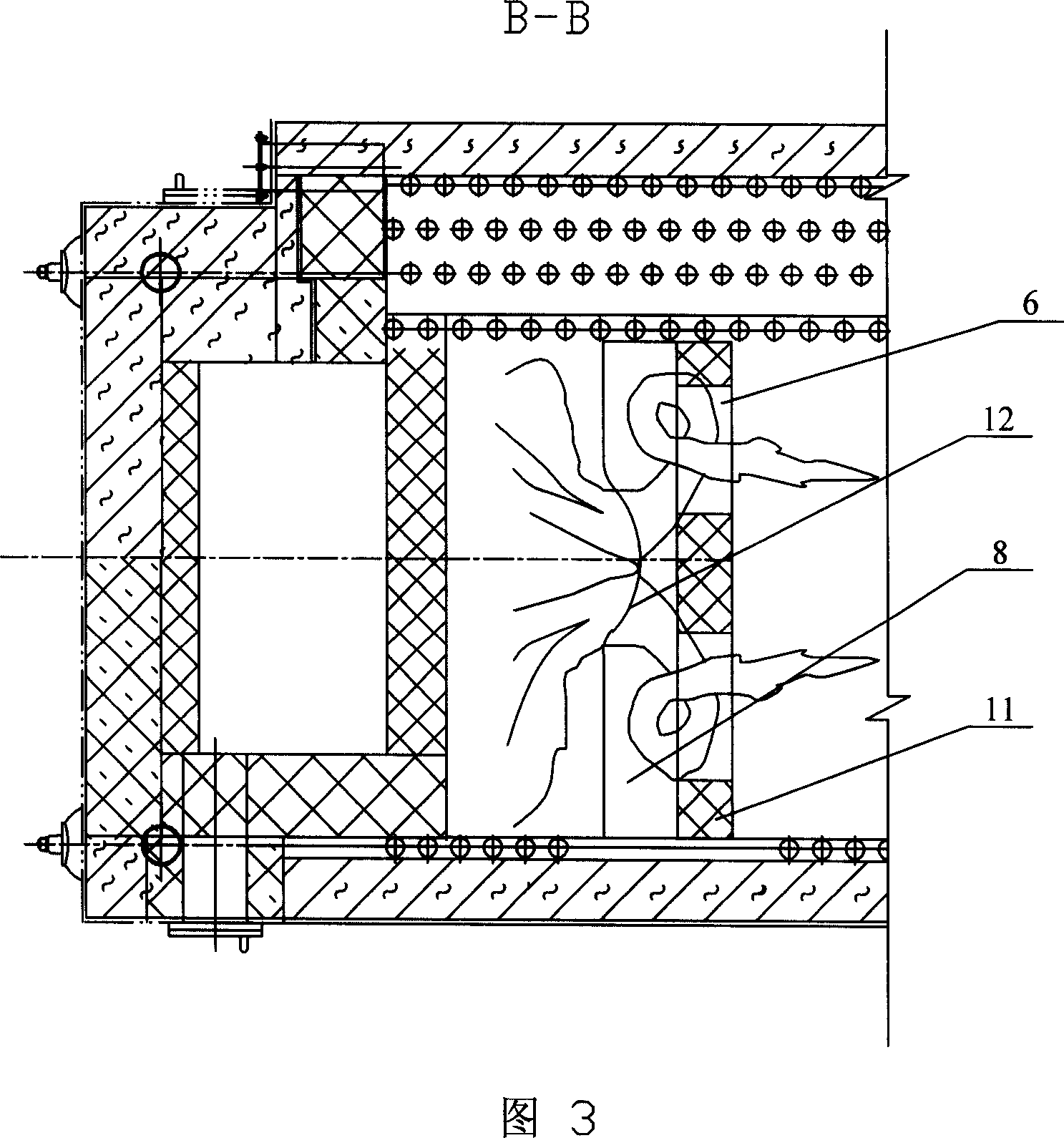

[0008] Specific Embodiment 2: This embodiment will be described in conjunction with FIG. 1 and FIG. 3 . The difference between this embodiment and the first embodiment is that it also includes a crescent-shaped 12 in the middle of the left end of the back arch 8 .

specific Embodiment approach 3

[0009] Specific Embodiment Three: This embodiment will be described in conjunction with FIG. 1 and FIG. 2 . The difference between this embodiment and the first embodiment is that it also includes a vertical wall 11 and a double tangential circular smoke separation hole 6, the vertical wall 11 is located above the left end of the back arch 8, and the vertical wall 11 and the rear arch 8 are connected as a One-piece, double-cut circular smoke and dust separation holes 6 are symmetrically opened on the vertical wall 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com