Vibration-isolating mount device

A technology of anti-vibration installation and vibration acceleration, applied in the direction of shock absorber, shock absorber-spring combination, spring, etc., can solve the problems of inability to absorb the top load, reduce the durability of the cab, and residual vibration, etc., and achieve good Anti-vibration effect, effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

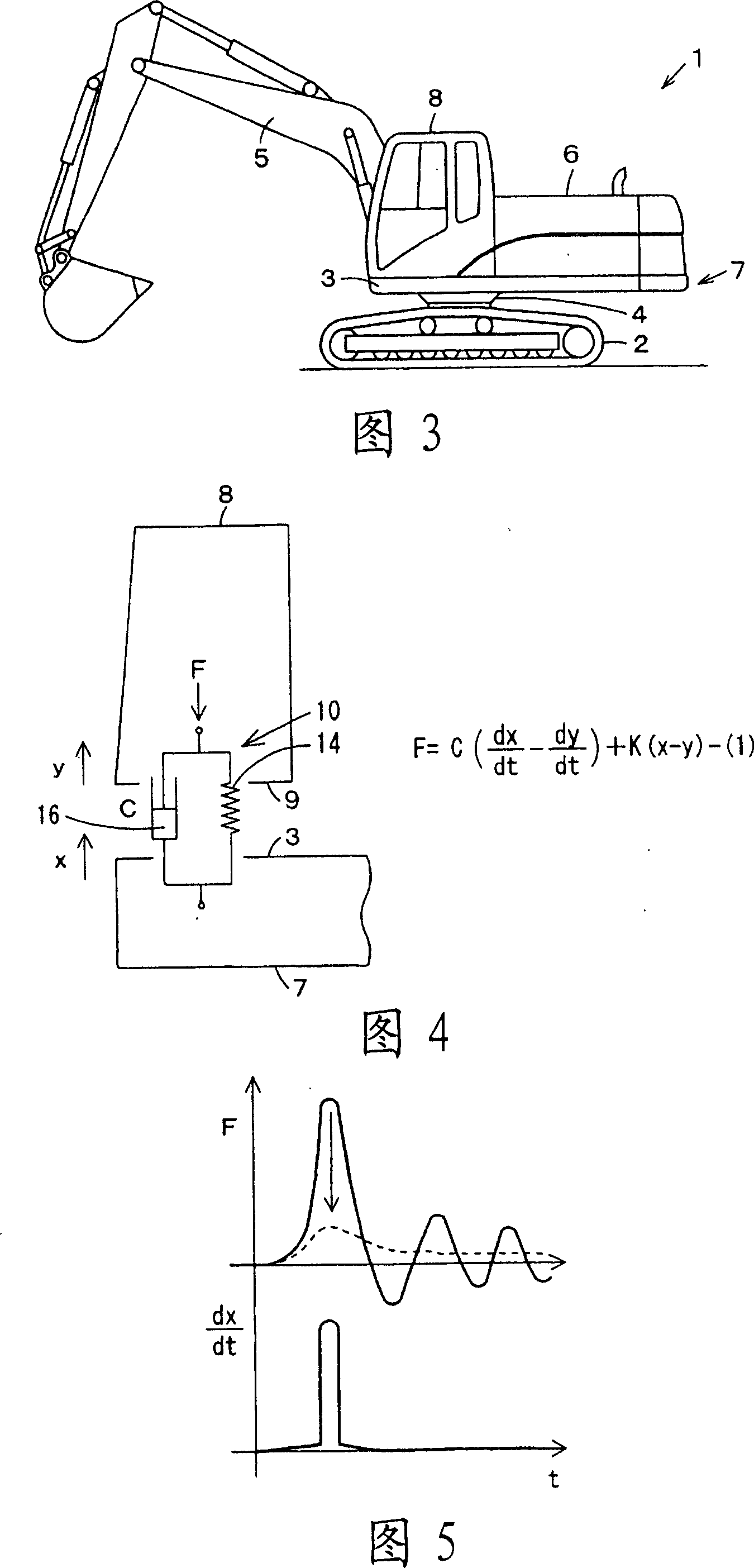

[0030] One embodiment of the anti-vibration mounting device of the present invention will be described with reference to the drawings.

[0031] In FIG. 3 , 1 denotes a hydraulic excavator as a working machine. This hydraulic excavator 1 has a crawler-type undercarriage 2 , and a swivel frame 3 as a substantially plate-shaped mounting base member to be able to go up and down through a swivel bearing portion 4 . It is provided on the undercarriage 2 so as to rotate around an axis (not shown) in the direction. In addition, the body 7 is constituted by the undercarriage 2 , the swivel bearing 4 , and the swivel frame 3 .

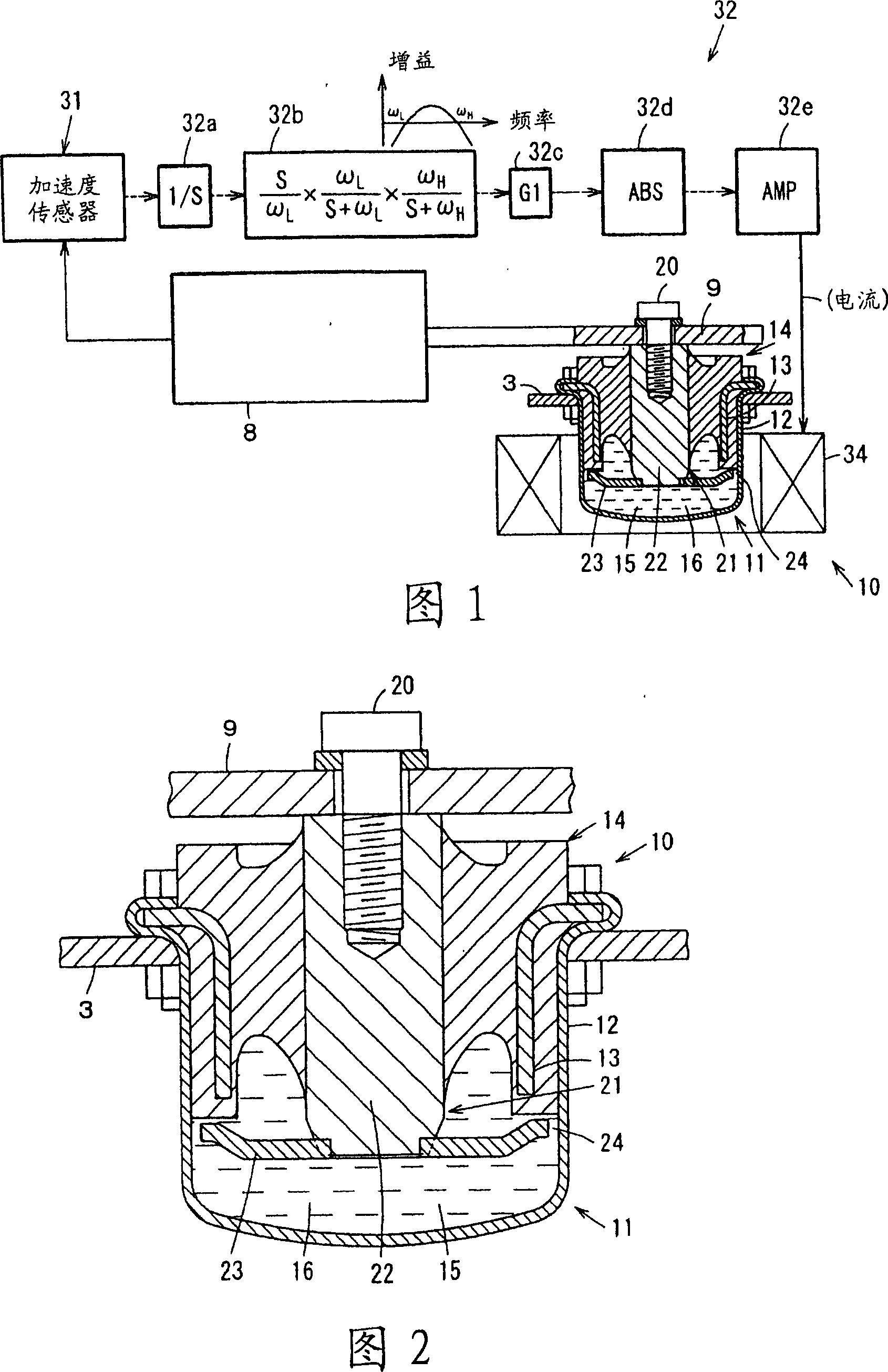

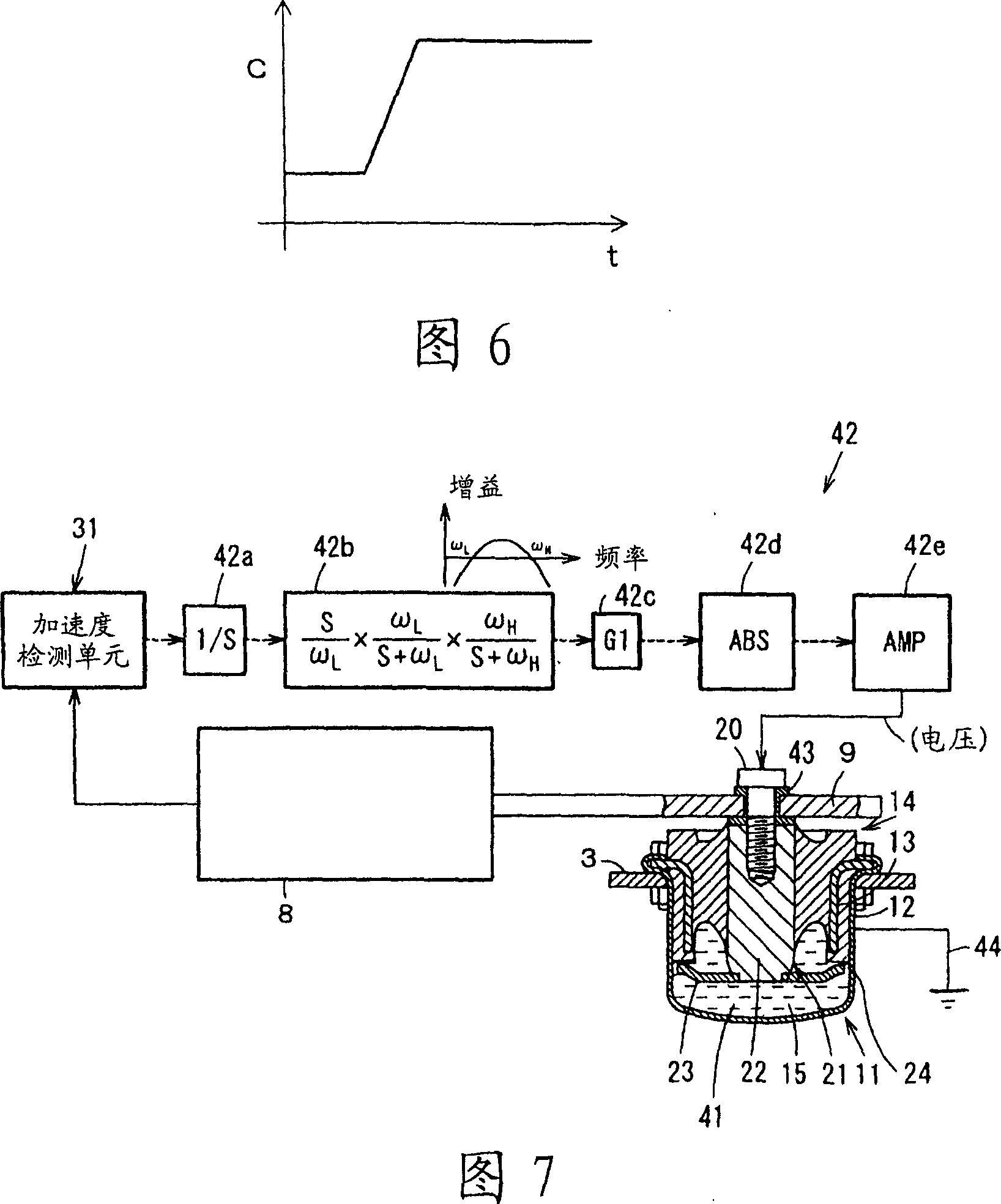

[0032] Further, on the swivel frame 3 of the machine body 7, a working device 5 for performing excavation work is provided, and a power unit 6 including an engine, a hydraulic pump driven by the engine, and the like is provided. As shown in FIGS. 1 and 2 , a substantially plate-shaped cab floor member 9 of the cab 8 is provided on the swivel frame 3 via a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com