Double-side suction type multi-tube dust filter

A dust filter, double-sided technology, applied in the field of dust filter equipment, can solve problems such as increased cost, large plant area, and unfavorable transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

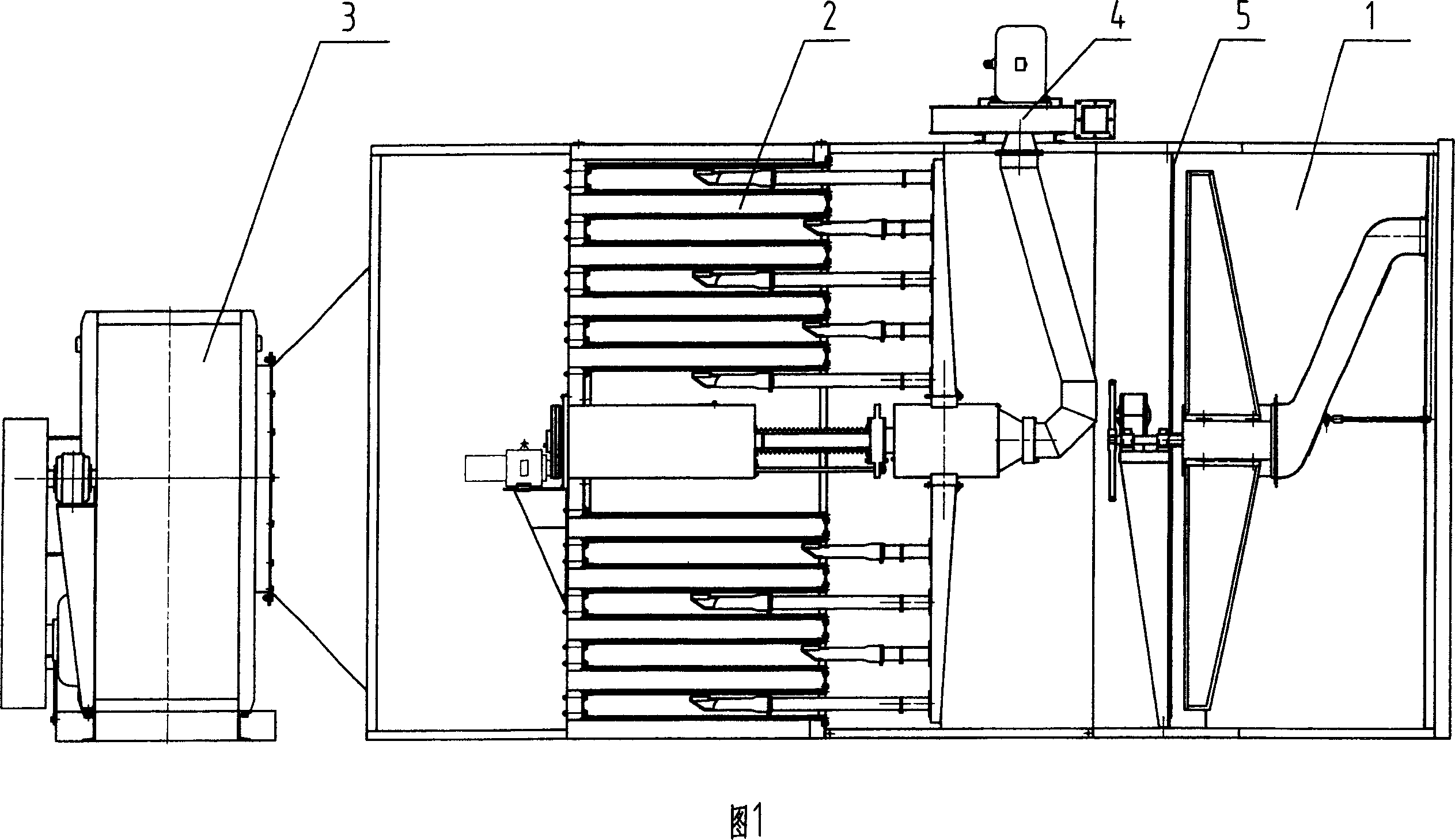

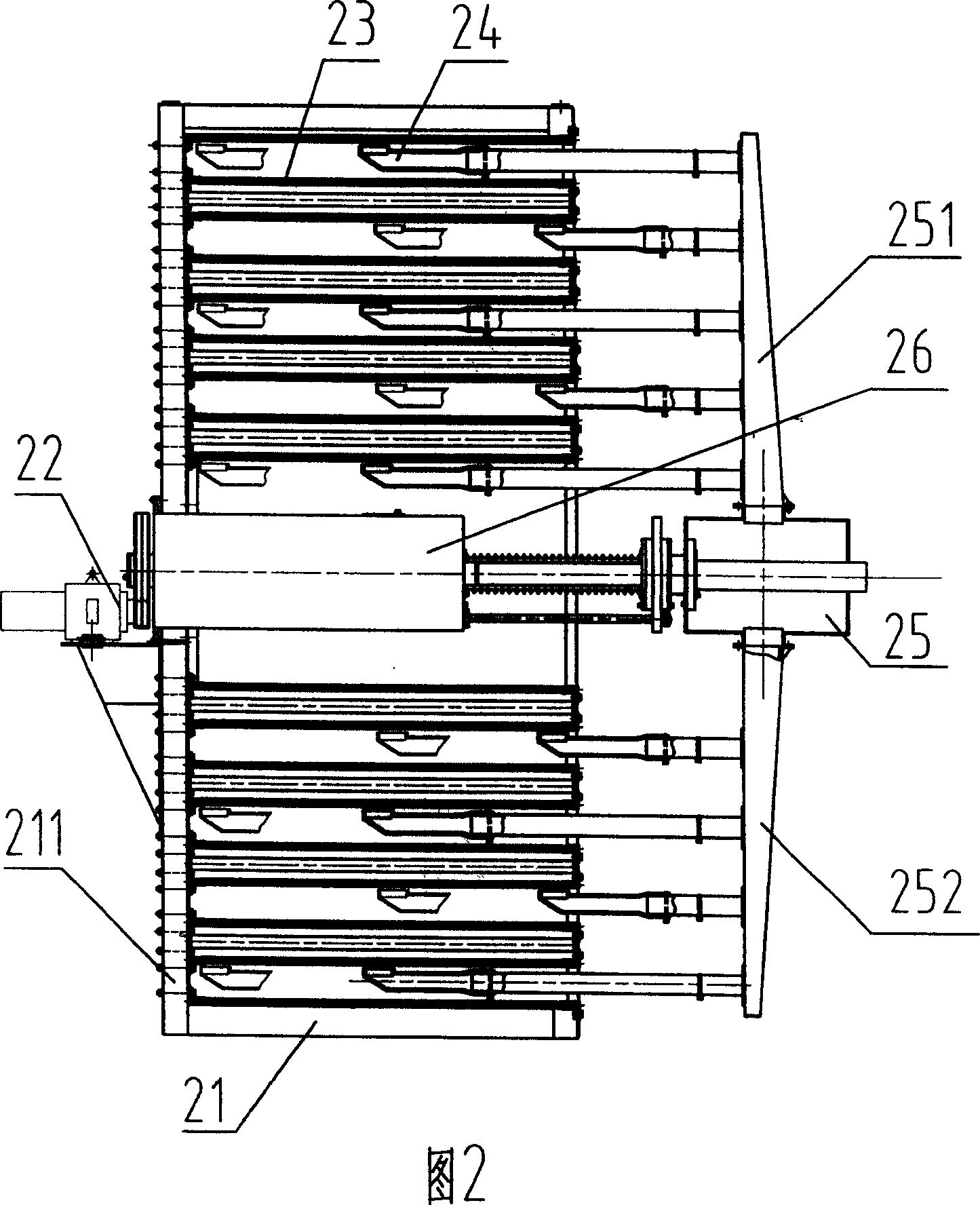

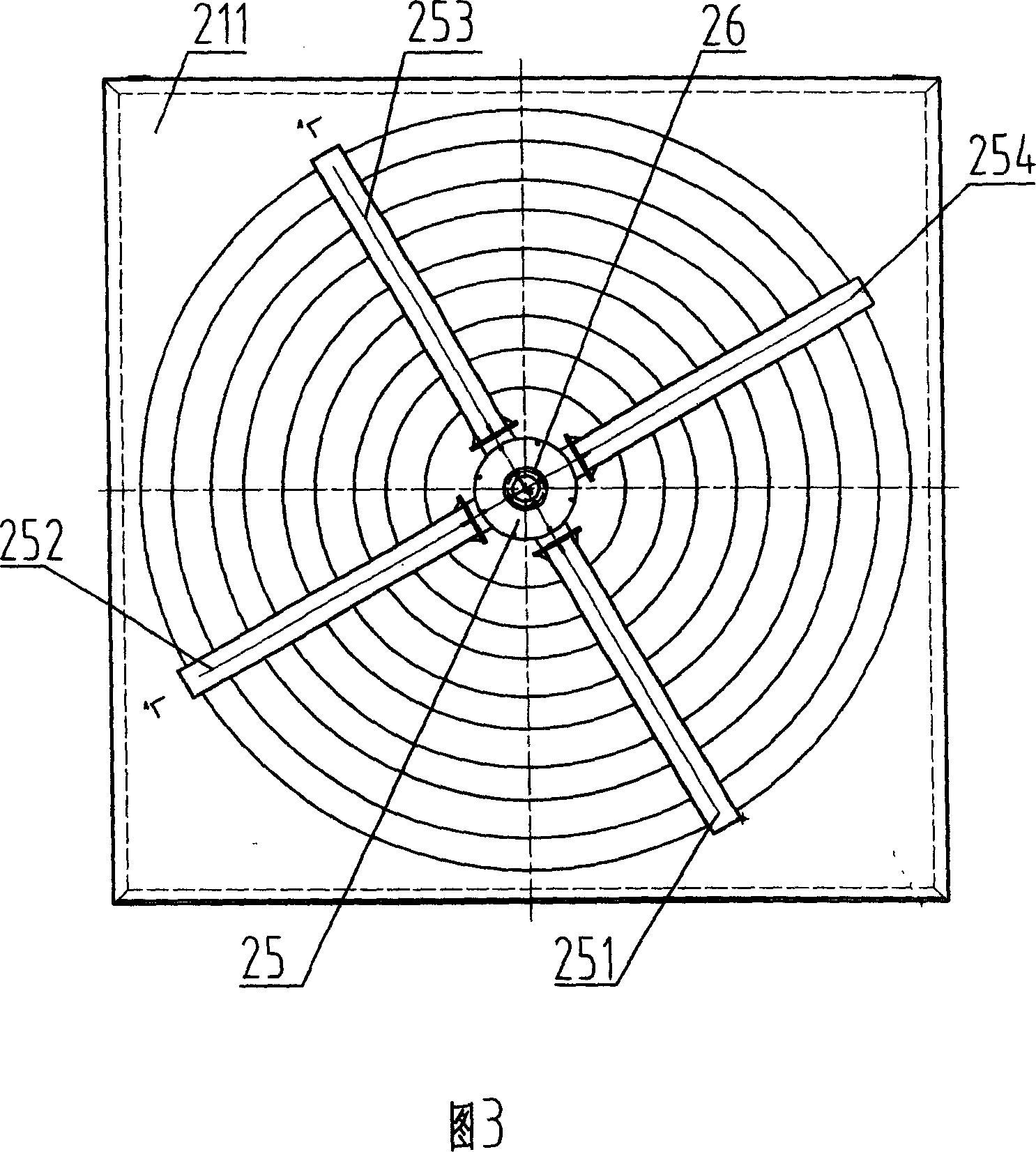

[0014] As shown in Figures 1 to 4, the multi-tube dust filter for double-sided dust suction includes a disc primary dust filter room 1, a multi-tube dust filter room 2, a main suction fan 3, a dust collection fan 4, and a disc primary dust filter room. 1 is connected in series with the multi-tube dust filter chamber 2 and then connected to the main suction fan 3, and a primary filter screen 5 is provided between the disc primary dust filter chamber 1 and the multi-tube dust filter chamber 2, and the multi-tube dust filter chamber 2 includes a frame 21, Suction nozzle operation motor 22, circular dust filter cylinder 23, suction nozzle 24, suction nozzle frame 25 and reciprocating screw mechanism 26, each circular dust filter cylinder 23 and reciprocating screw mechanism 26 are all fixed on the rice-shaped frame on the left side of the frame 21 211, and the reciprocating screw mechanism 26 is arranged in the central dust filter cylinder, and the axes of the two coincide. Each ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com