Thawing room combined parts and quick freezing chamber combined parts for refrigerator

A technology for rapid freezing and thawing chambers, which can be used in household refrigeration devices, cooling fluid circulation devices, lighting and heating equipment, etc., and can solve problems such as inability to thaw frozen objects more effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

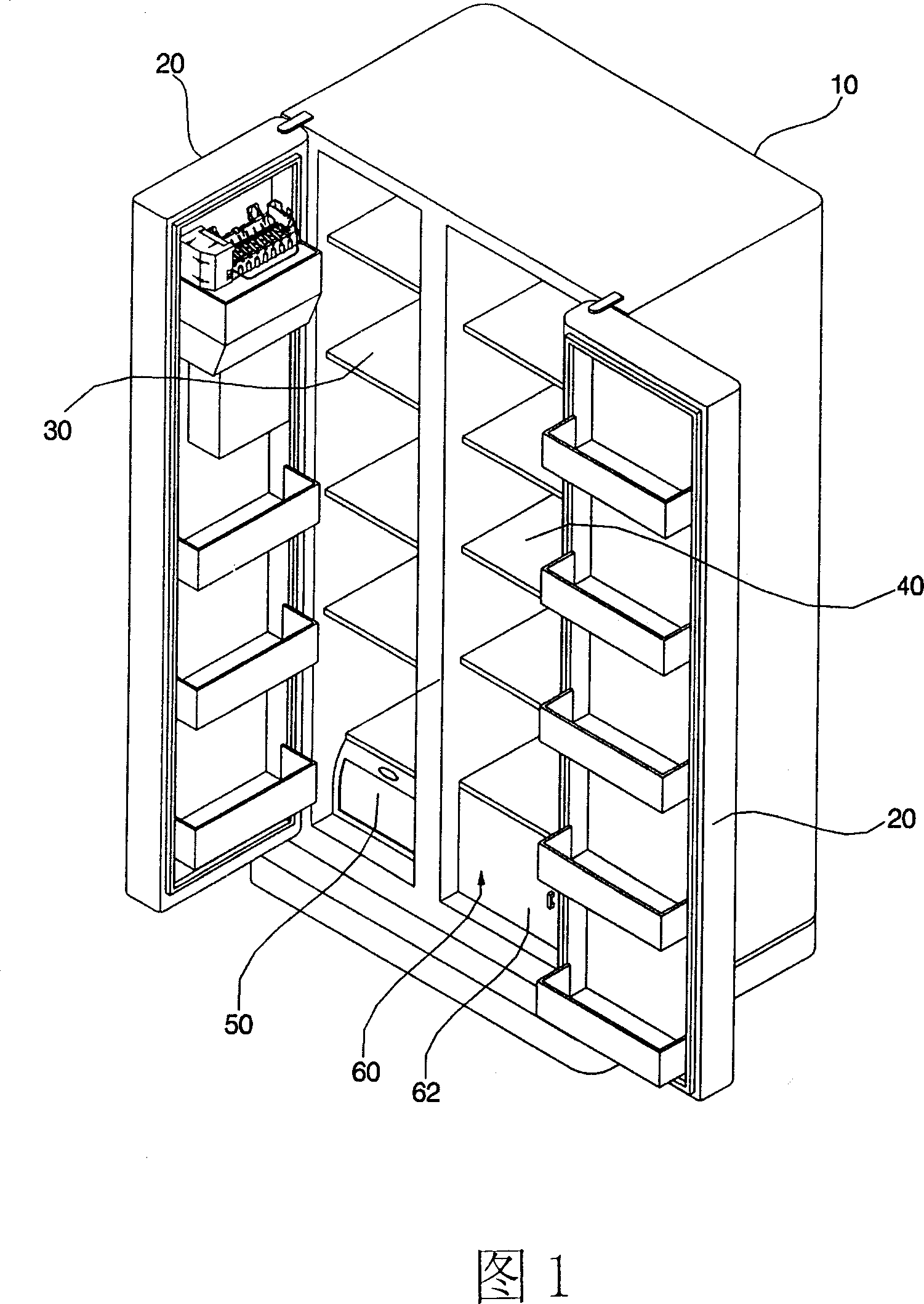

[0052] As shown in Fig. 1, the refrigerator of the present invention includes the following parts: a main body 10 that forms an outer shape; a door 20 provided on the front of the main body 10; , Vegetable room 50 and thawing room 60.

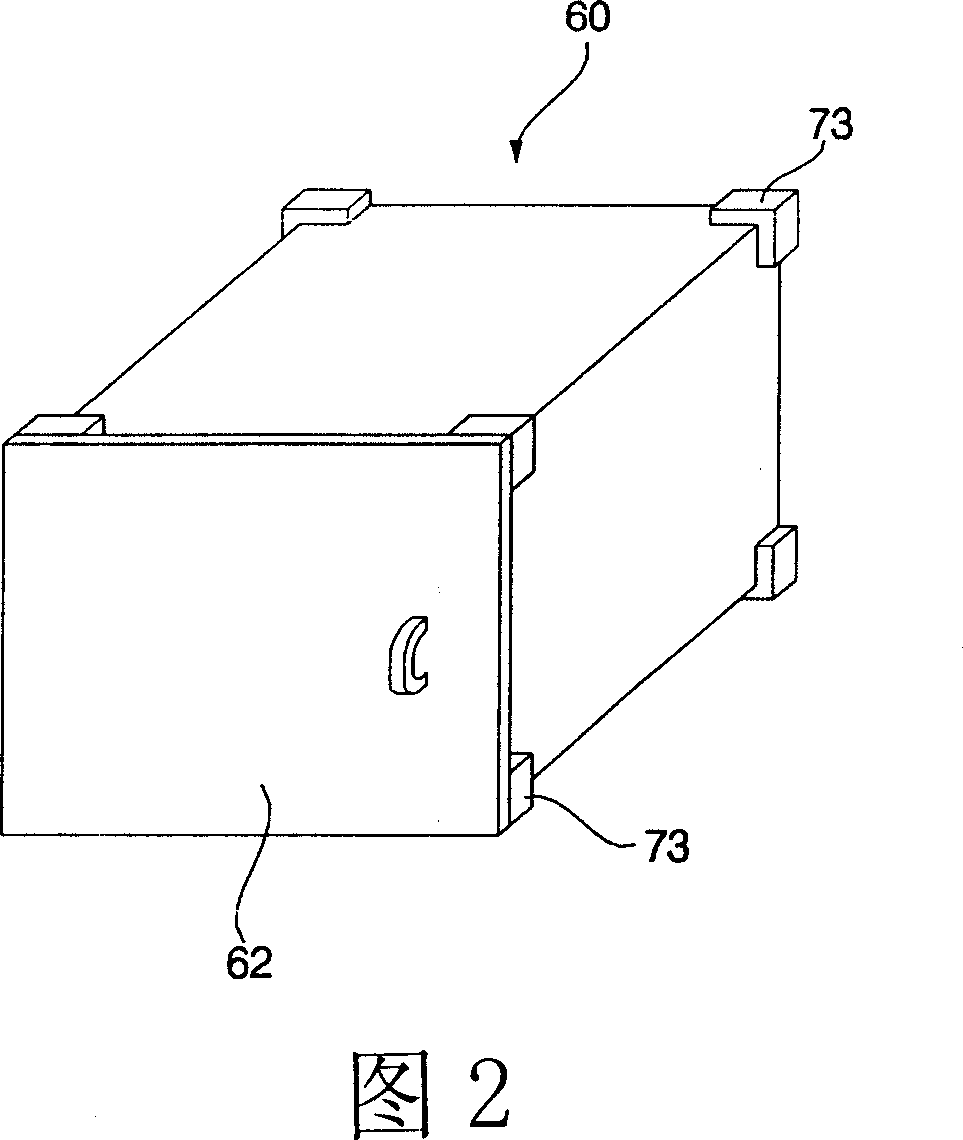

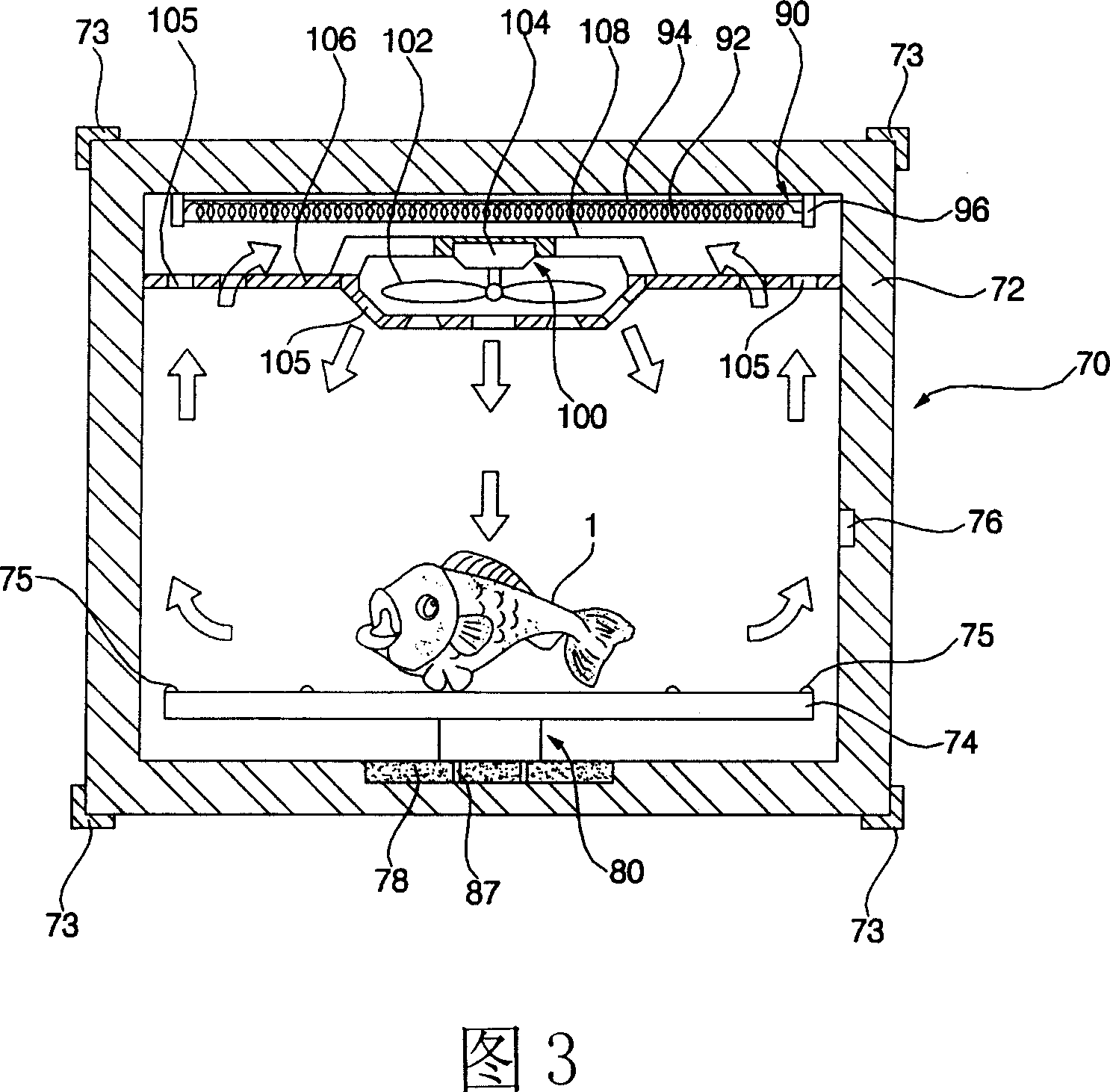

[0053] As shown in FIG. 2 or FIG. 3, the thawing chamber 60 of the present invention includes the following parts: a thawing chamber assembly 70 arranged inside the main body 10; assembled on the front of the thawing chamber assembly 70 to open and close the thawing chamber The thawing chamber door 62 on the front of the assembly 70.

[0054] The thawing chamber assembly 70 includes the following parts: a thawing chamber body 72 fixedly arranged inside the main body 10; a thawing plate 74 arranged inside the thawing chamber body 72; and a thawing plate 74 arranged on the thawing plate 74 to make the thawing plate 74 Vibrating vibrating device 80; heating device 90 installed inside the thawing chamber body 72 to heat the air inside the thawing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com