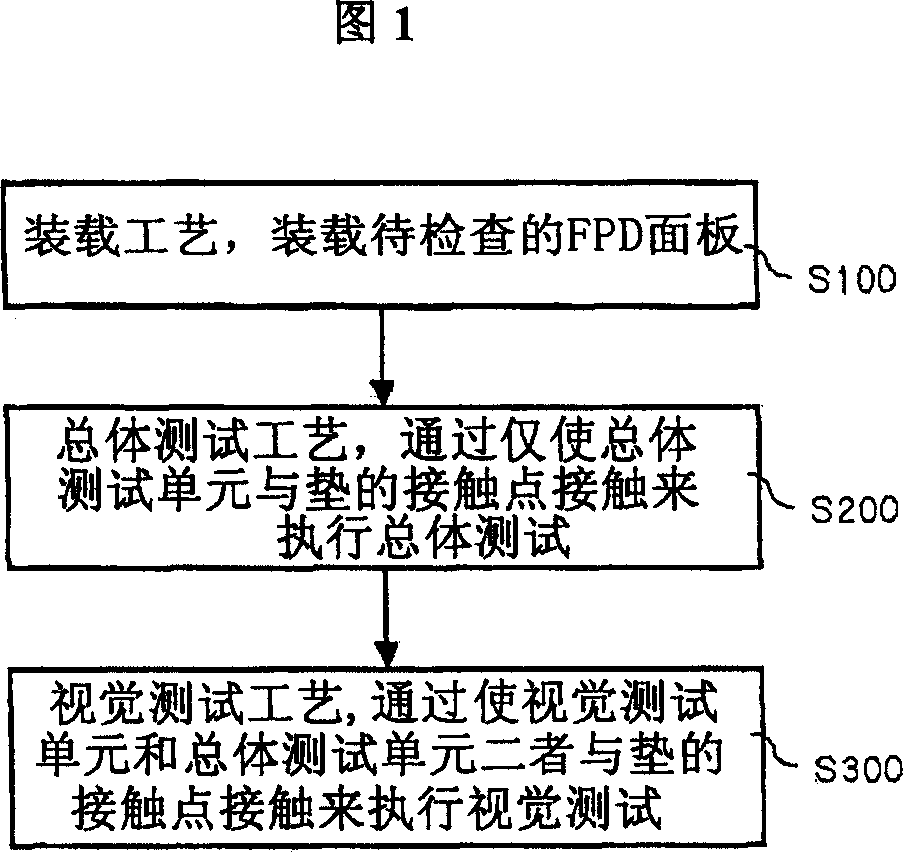

Inspection method and apparatus of flat display pane

A technology of inspection devices and inspection methods, applied in the directions of electrical devices, measuring devices, transportation and packaging, etc., which can solve the problems of time, labor and space doubling, impossible module process visual testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

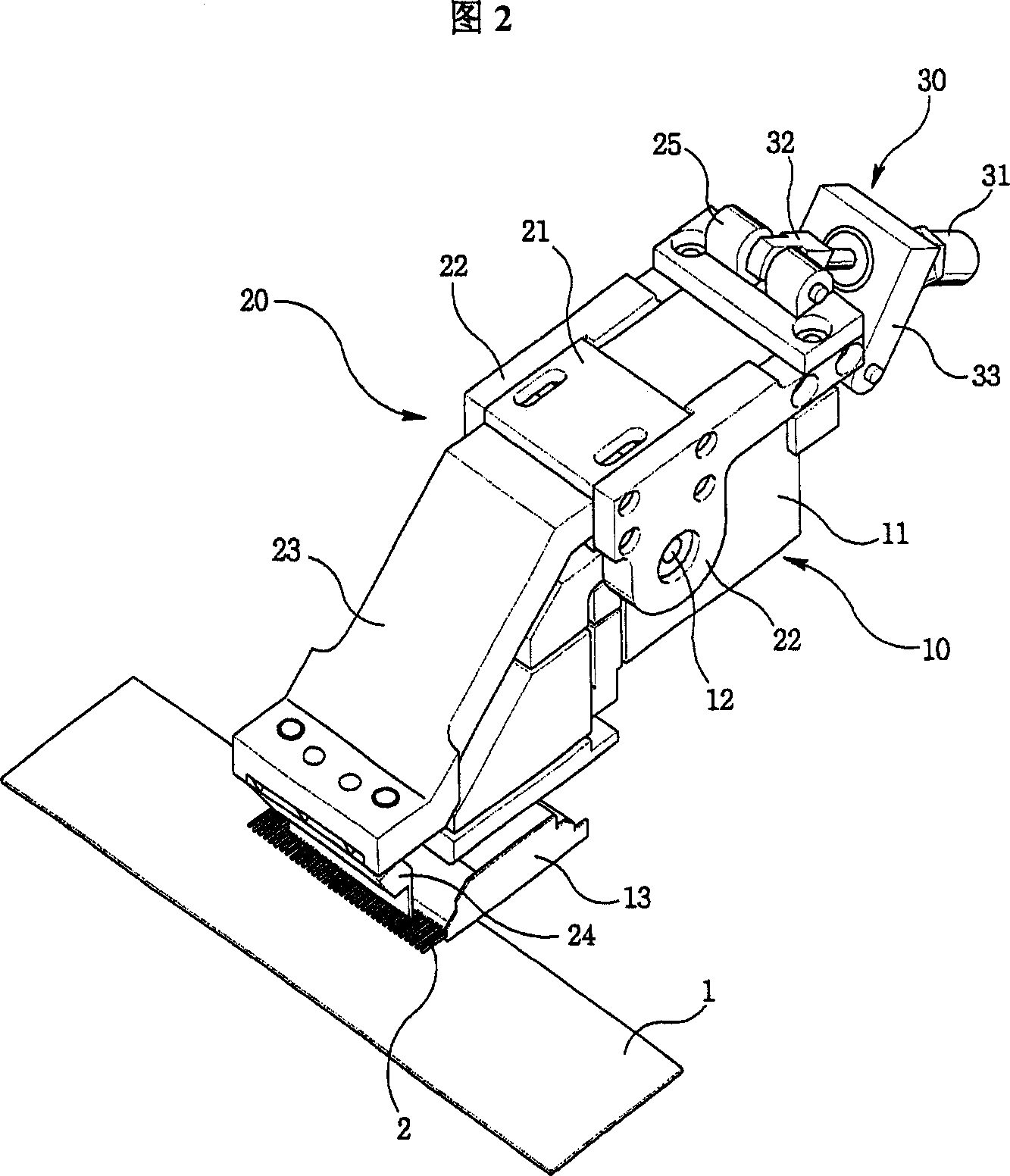

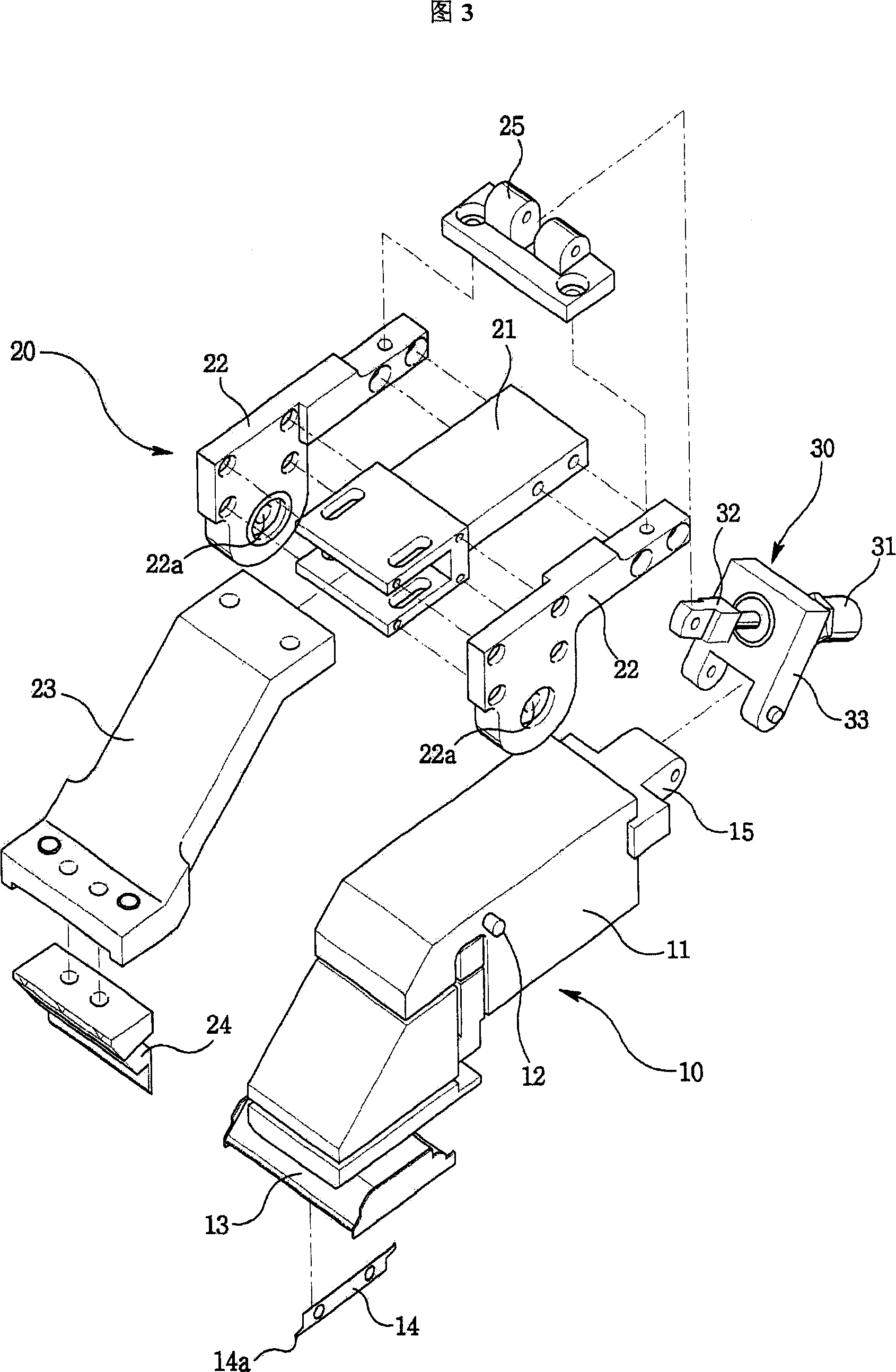

[0036] With reference to Fig. 2, Fig. 2 illustrates a FPD inspection device according to the first embodiment of the present invention, and this FPD inspection device comprises: overall test probe unit 10, it is used to carry out overall test to FPD panel; Vision test probe unit 20, it uses For performing the visual test on the FPD panel, the visual test probe unit 20 is hingedly connected to the overall test probe unit 10 in a pivotable and rotatable manner; and a pivot unit 30 for making the visual test probe unit 20 relative to the overall test probe unit 10 pivotally rotates.

[0037] The overall test probe unit 10 includes: a frame 11 having one or more hinged connection parts 12 ;

[0038] Specifically, the frame 11 of the overall test probe unit 10 having a predetermined shape occupies a part of the FPD inspection device, and is coupled at its front end to the overall test probe case 13 in which the overall test probe 14 is accommodated to The overall test probe unit 1...

no. 2 example

[0065] Referring to Figures 6 to 9 illustrating an FPD inspection device according to a second embodiment of the present invention, the inspection device includes: a main connection frame 100, a plurality of overall testing units 109; a plurality of vertical moving units 135; a sub-connection frame 126; a plurality of visual test cells 119; and a plurality of resilient members 124. Through the use of the fastening member 102, a plurality of overall test units 109 for performing an overall test on the FPD panel are fixedly installed on the main connection frame 100 such that they are spaced apart from each other by a constant distance. Through the use of fastening parts 102, a plurality of vertical moving units 135 are also fixedly installed on the main connecting frame 100, so that each vertical moving unit 135 is located between two adjacent overall testing units 109 on the main connecting frame 100 between. The vertical moving unit 135 is used to bring the vision test unit ...

no. 3 example

[0089] The FPD inspection device according to the third embodiment of the present invention shown in FIGS. 10 to 12 is slightly different from the FPD inspection device according to the second embodiment of the present invention. Accordingly, descriptions of elements having the same structure as those of the second embodiment will be omitted, and only differences therebetween will be described hereinafter.

[0090] The main difference between the second embodiment of the present invention and the third embodiment includes: the structural feature of the bending piece 134 of the vertically moving unit 135 fixed to the sub-connection frame 126, and the connection between the sub-connection frame 126 and the visual test unit 119 connection structure.

[0091] In the third embodiment shown in FIG. 10 , the plurality of bending pieces 134 connected and fixed to the main body 110 of each vertical moving unit 135 of the second embodiment is replaced by a bending member 300 having a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com