Linear motor operating mechanism of high-voltage breaker

A high-voltage circuit breaker, linear motor technology, applied in the protection switch operation/release mechanism, electric components, electrical components, etc., can solve the problems of uncontrollable movement process, unreliable long-term operation, and large action dispersion, and achieve a simple structure. Reliable, light weight, controllable effect during movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

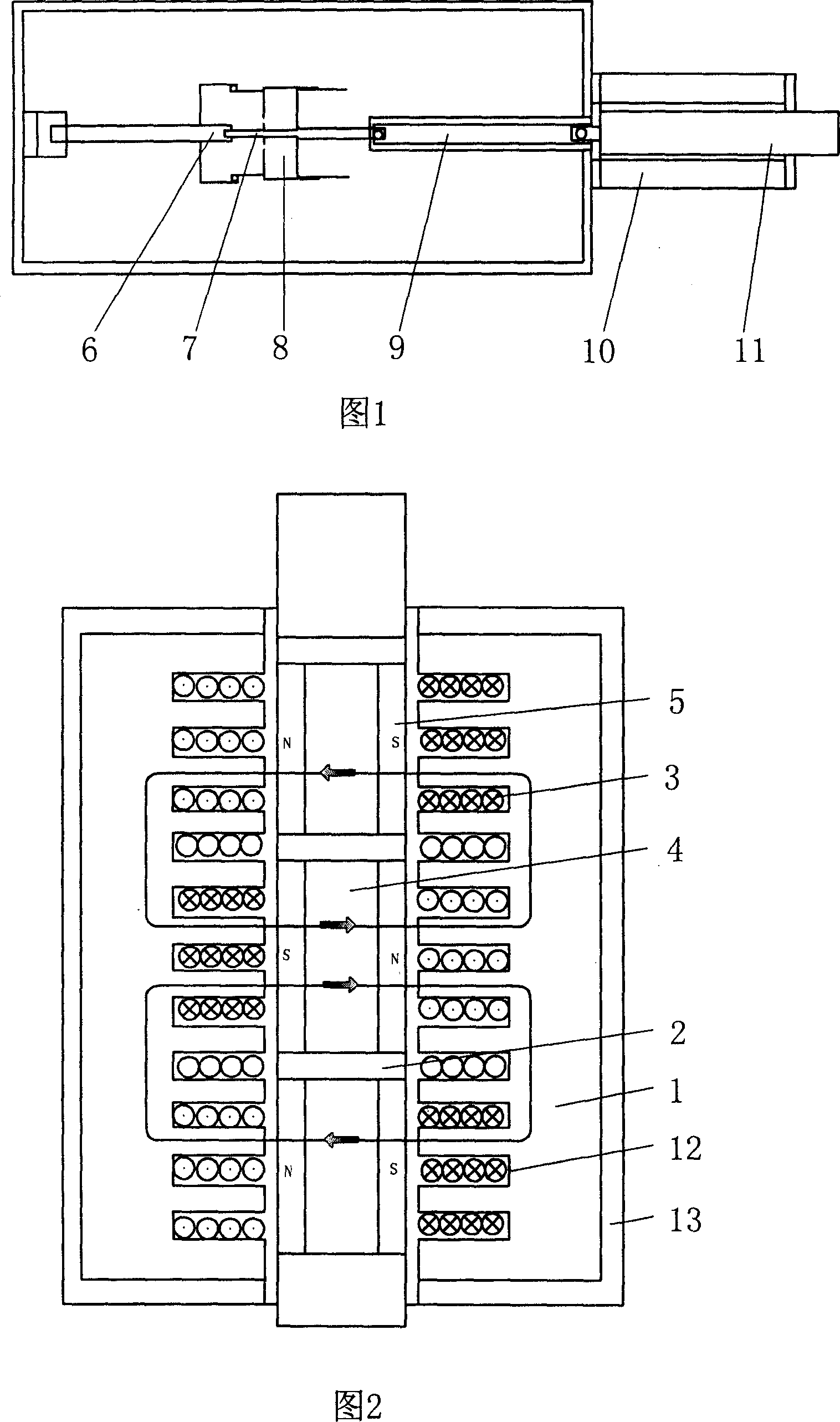

[0045] Embodiment: As shown in Figure 1, the present invention includes a linear motor and a servo controller, the secondary 11 of the linear motor and the moving contact 7 of the high-voltage circuit breaker are connected through an insulating pull rod 9, and the linear motor 18 passes through the armature on it Winding 3 and position and speed sensors are connected to the servo controller.

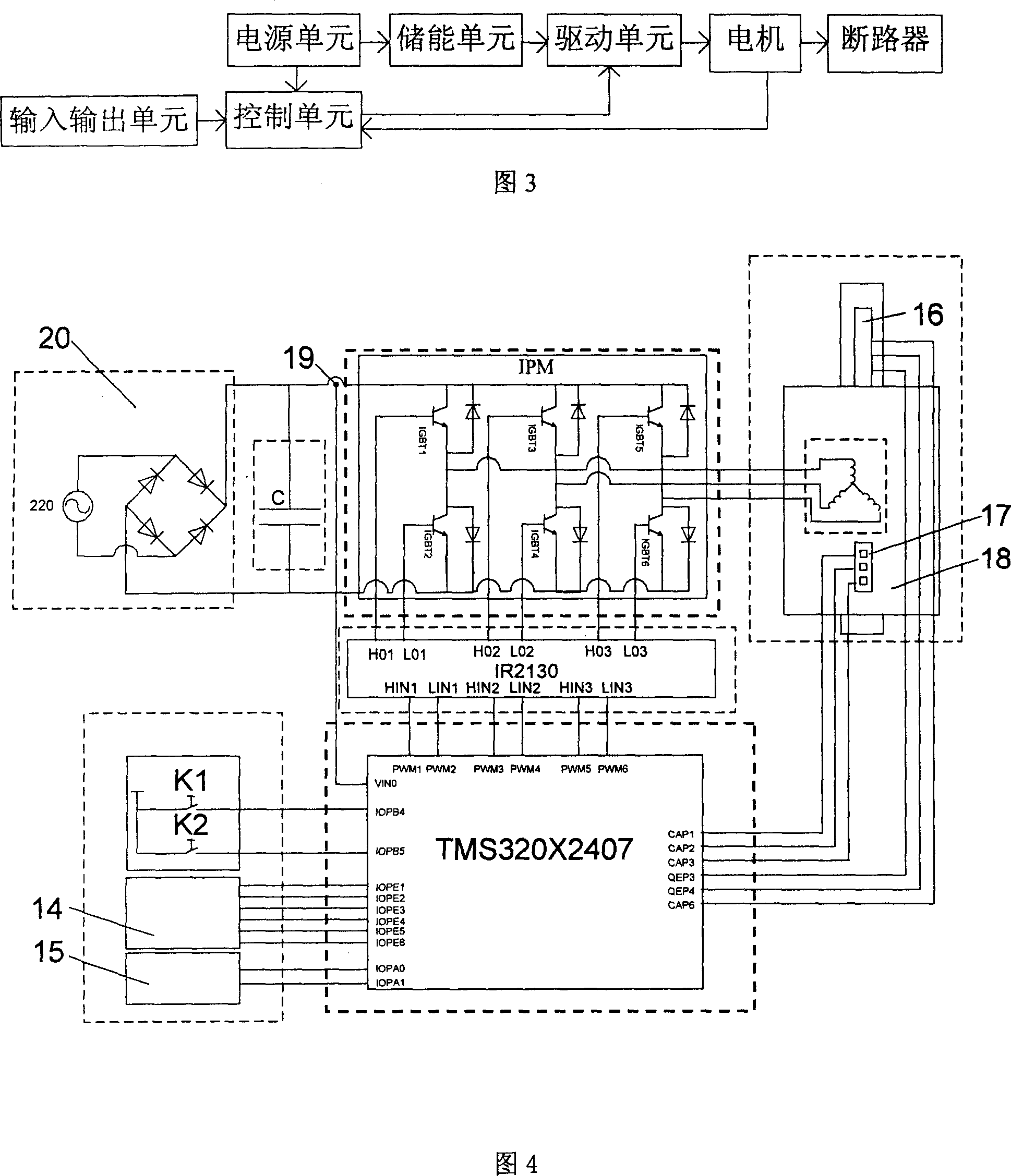

[0046] The structure of the linear motor is shown in Figure 2, including primary iron core 1, secondary iron core 4, permanent magnet 5, position and speed sensors, which are distributed sequentially from inside to outside along the radial direction: secondary iron core 4, armature winding 3, primary Iron core 1, housing 13, primary iron core 1 is made of silicon steel sheets laminated into several groove-shaped structures, armature winding 3 is placed in the groove 12 on the side opposite to secondary iron core 4, and secondary iron core 4 is sequentially embedded with Permanent magnets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com