Microemulsion with high heat stability

A microemulsion and droplet technology, applied in the field of microemulsion, can solve the problems of poor temperature resistance, damage stability, and high production cost, and achieve the effects of wide temperature range, good stability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

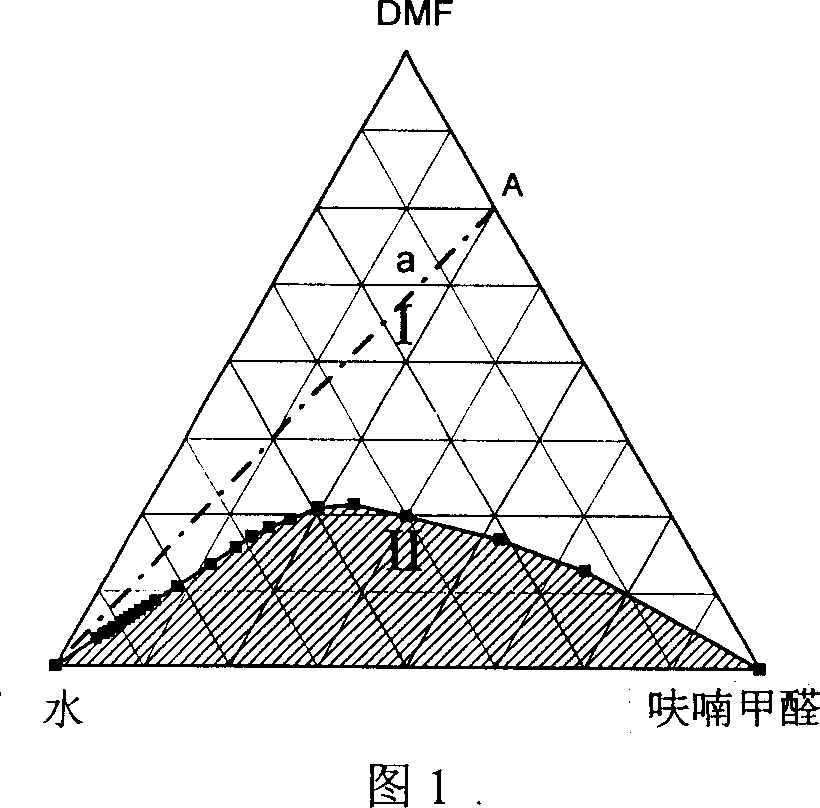

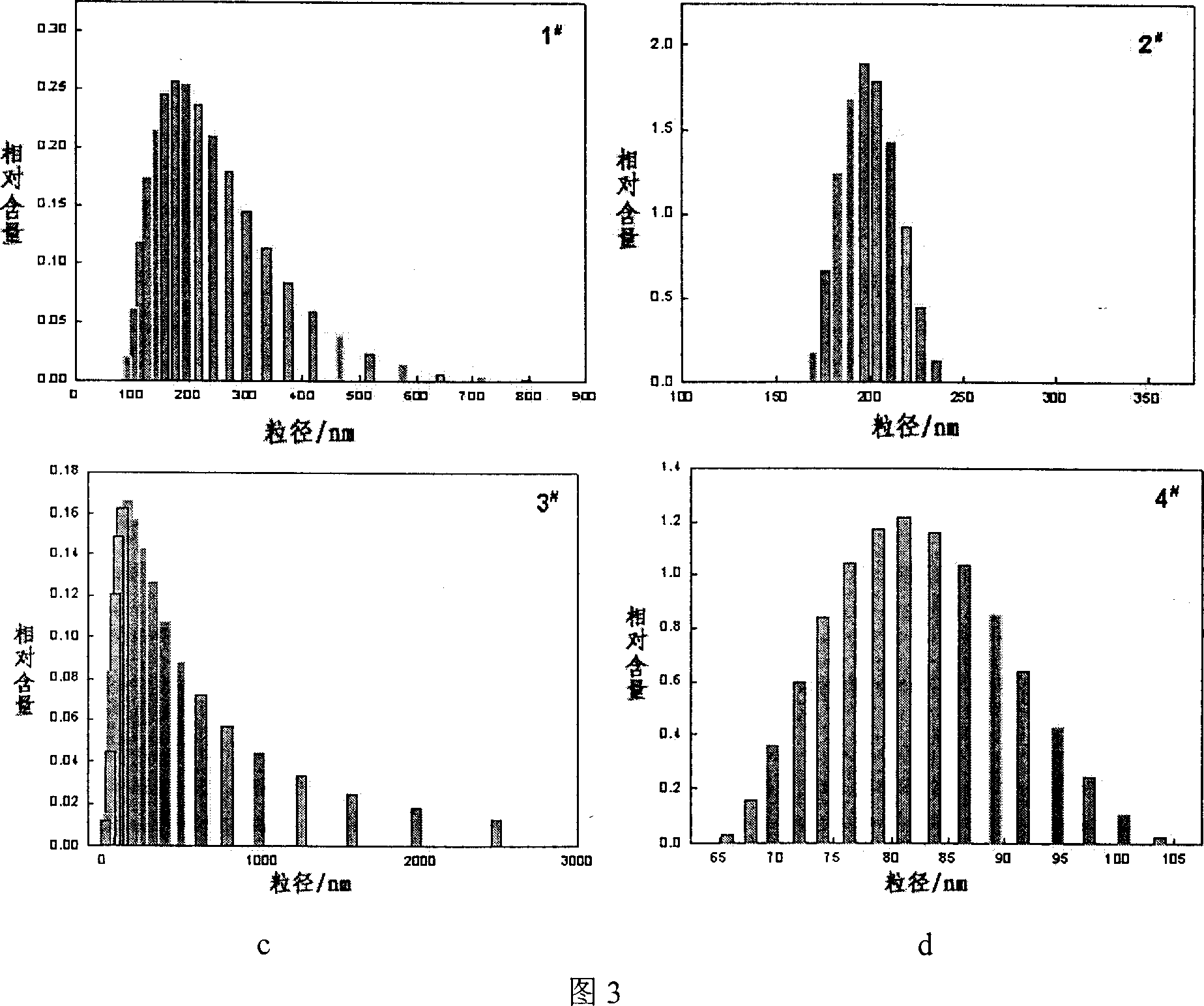

[0028] The oil phase is furfural, the emulsifier is N,N-dimethylformamide (DMF), and the water phase is water. Mix uniformly according to the volume ratio of N, N-dimethylformamide: furan formaldehyde: water = 3:1:1, 3:1:4, 3:1:6 and 3:1:8 to obtain a microemulsion sample 1 # -4 # . The ternary phase diagram is shown in Figure 1. Point A in the ternary phase diagram is N, N-dimethylformamide: furan formaldehyde = 3:1. Select different samples 1 along the line a # -4 # The measured particle size is shown in Table 1 and Figure 3. The particle size decreases gradually from the water angle. The cryo-etching scanning electron microscope photo of the sample is shown in Figure 2, and it can be observed that the shape of the droplet is spherical. Freeze-thaw cycle, centrifugation, heat storage, refrigeration and other treatments did not find delamination or other damage to the uniformity, indicating that the system has ultra-high stability. The results are shown in Table 2.

...

Embodiment 2

[0032] The oil phase is xylene, the emulsifier is dimethyl sulfoxide, and the water phase is water. Its volume ratio is 3:1:4 to 3:1:8. Mix and stir. The measured particle size is 150-220nm. The stability test results are the same as Table 2.

Embodiment 3

[0034] Cyclohexane is used for the oil phase, ethanol (80%)-dimethylsulfoxide mixture with a volume ratio of 1:1 is used as the emulsifier, and water is used for the water phase. The volume ratio of the oil phase, emulsifier and water is 2:1:3-2:1:6. Mix and stir. The measured particle size is 110-200nm, and the stability test results are the same as Table 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap