Multiple rolling machine and its control method

A control method and rolling mill technology, which are applied in the rolling mill control device, metal rolling mill stand, metal rolling and other directions, can solve problems such as difficult shape control, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

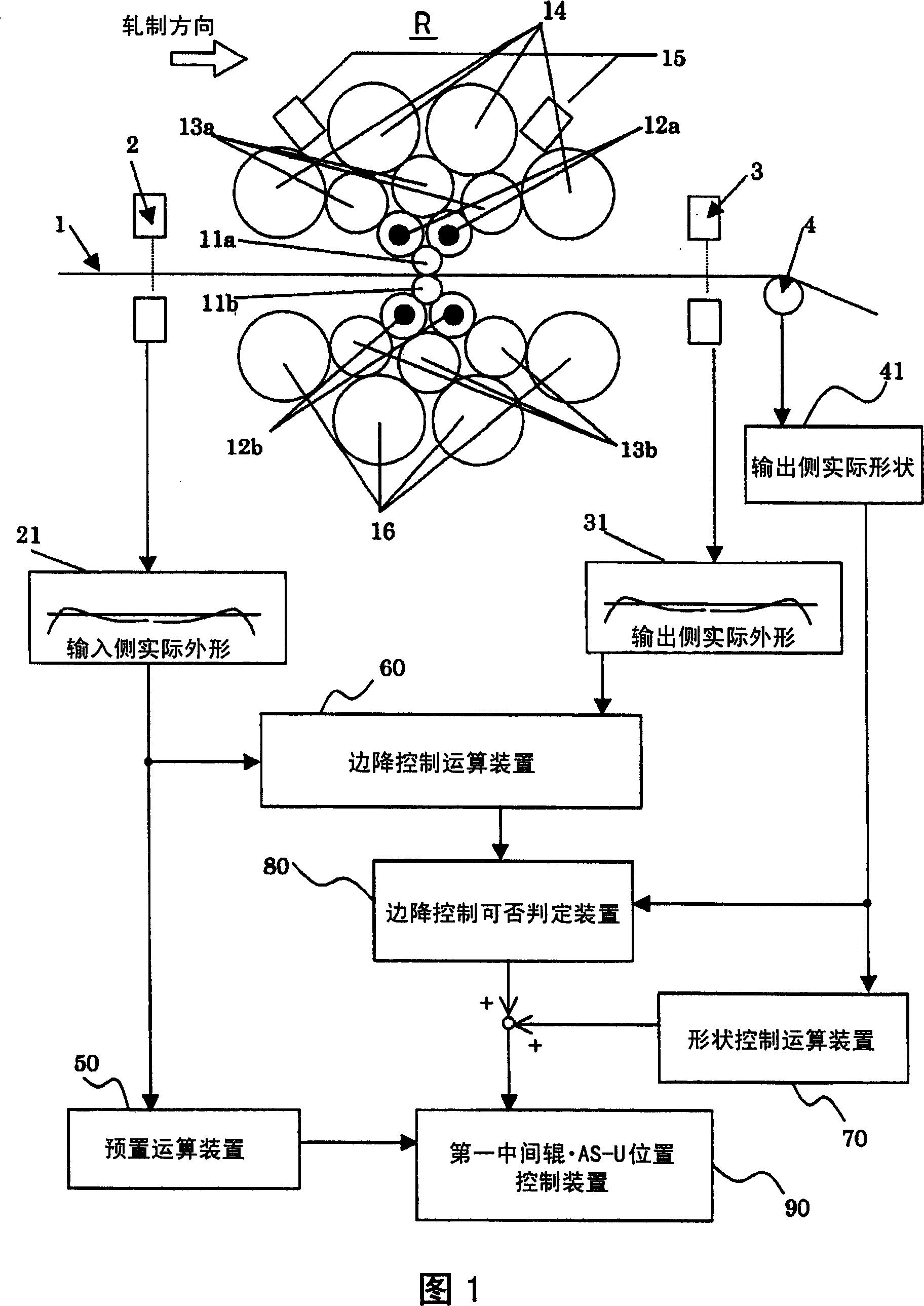

[0035] Hereinafter, the multi-roll rolling mill and its control method of the present invention will be described in detail through the illustrated embodiments. Herein, firstly, the rolling mill to be the application object of the present invention is a reversible rolling mill having intermediate rolls behind the work rolls. multi-roll mill.

[0036] In addition, there are 12-high rolling mills and 20-high rolling mills as representative rolling mills of this multi-high rolling mill, but in the following embodiments, an example in which the present invention is applied to a 20-high rolling mill will be described.

[0037] FIG. 1 is an embodiment of the present invention. As mentioned above, it is an embodiment in which the present invention is applied to a 20-high rolling mill. Since it is a reversible rolling mill at this time, the rolling direction is switched every pass, but In FIG. 1 , for the sake of simplicity, the rolling of the rolled material 1 is shown from left to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com