Robot control device and robot system

A robot system and control device technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of expanding the extension area of cables and increasing the occupied area of robot systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

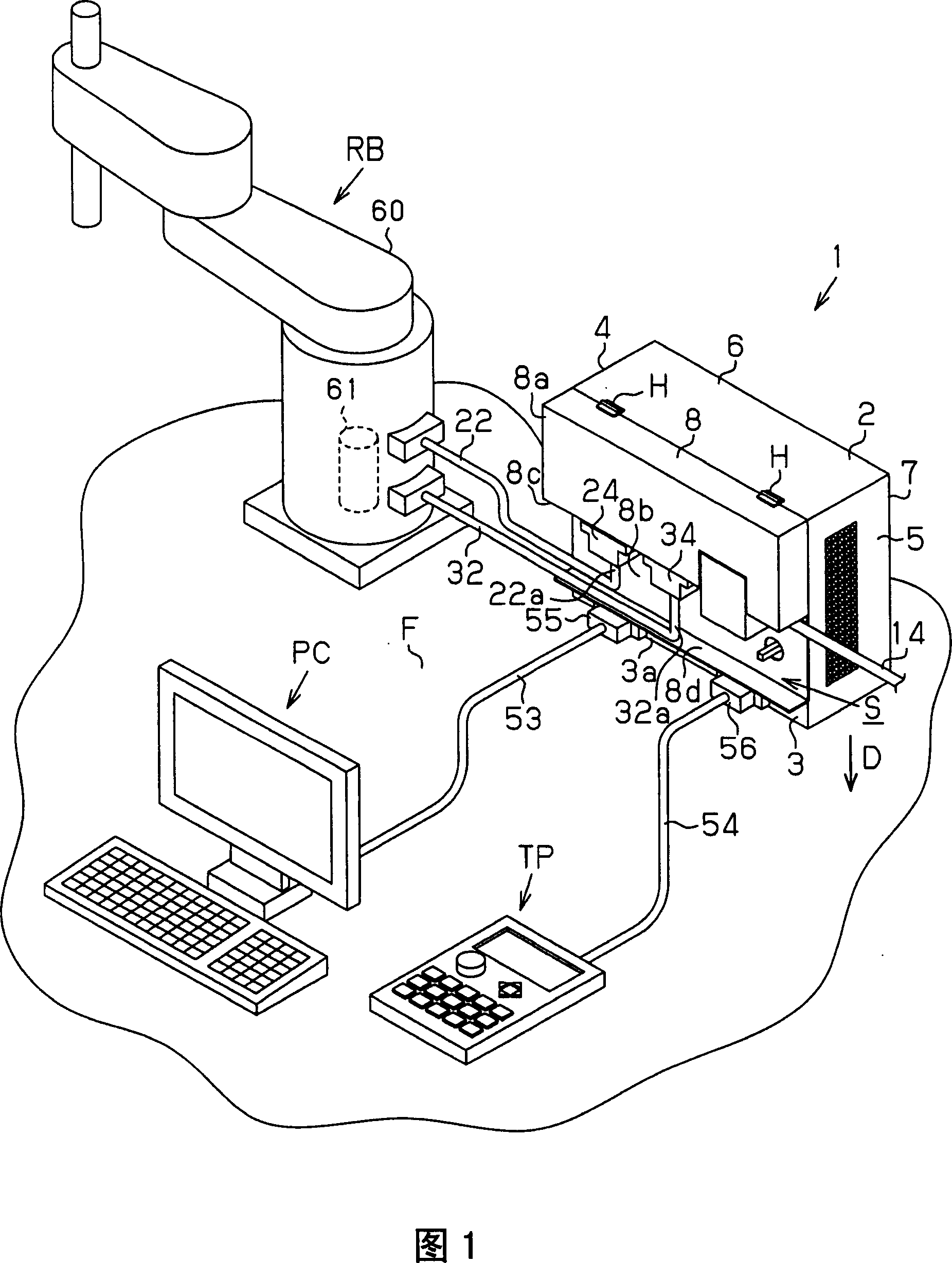

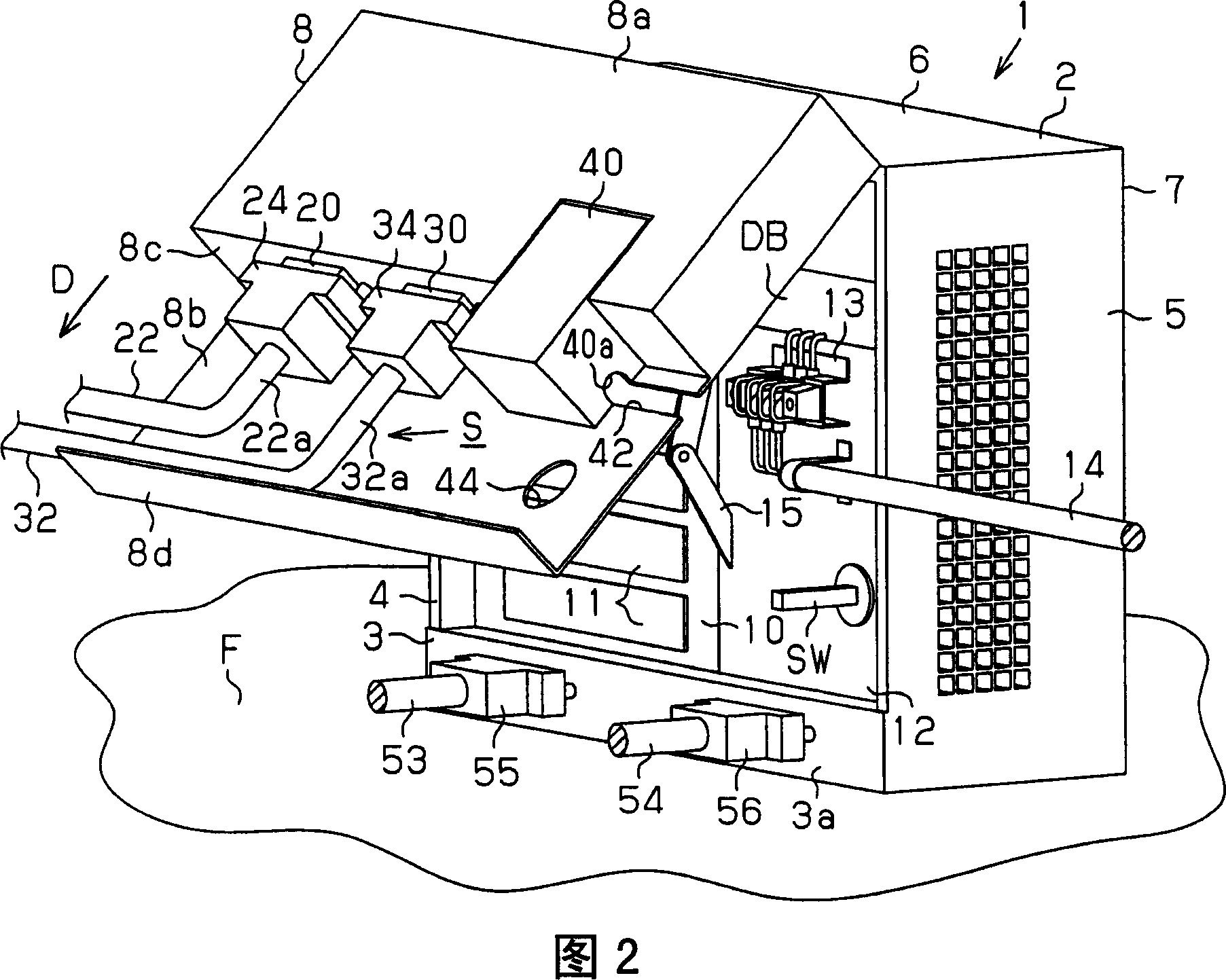

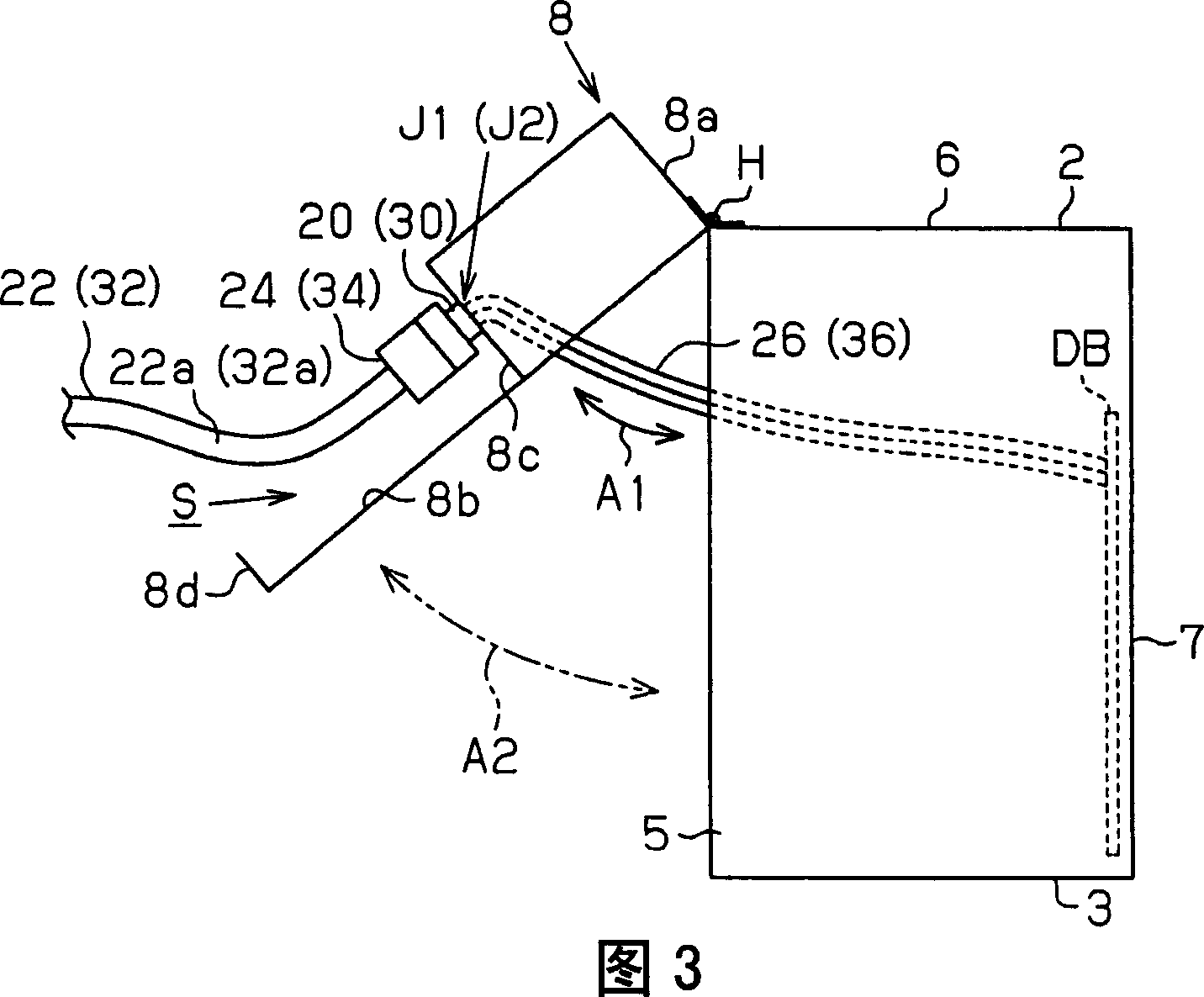

[0017] Next, an embodiment of the present invention will be described with reference to FIGS. 1 to 3 .

[0018] As shown in FIG. 1 , the robot system has an industrial robot RB and a controller 1 as a robot control device that drives the robot RB. The industrial robot RB includes a four-axis control type horizontal multi-joint robot arm 60 and a motor 61 as an actuator for driving the robot arm 60 .

[0019] The controller 1 has a rectangular parallelepiped housing 2 installed on the installation surface F. As shown in FIG. The box body 2 has: a base 3 disposed on the installation surface F, a left plate 4 disposed on the left end of the base 3, a right plate 5 disposed on the right end of the base 3, a left plate 4 and a right plate The top plate 6 of 5 upper ends. The box body 2 also has: a back panel 7 closing the rear opening of the space surrounded by the base 3, the left panel 4, the right panel 5 and the top panel 6, and an opening and closing control panel 8 capable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com