Layered flavouring-soy-sauce yoghourt, yoghourt base material and mfg. method

A manufacturing method and a technology for flavored sauce, which are applied in the directions of milk preparations, dairy products, applications, etc., can solve the problems of low viscosity, difficulty in making lower-layer yogurt base material, and inability to prepare layered flavored sauce yogurt, etc., and achieve nutritional value. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

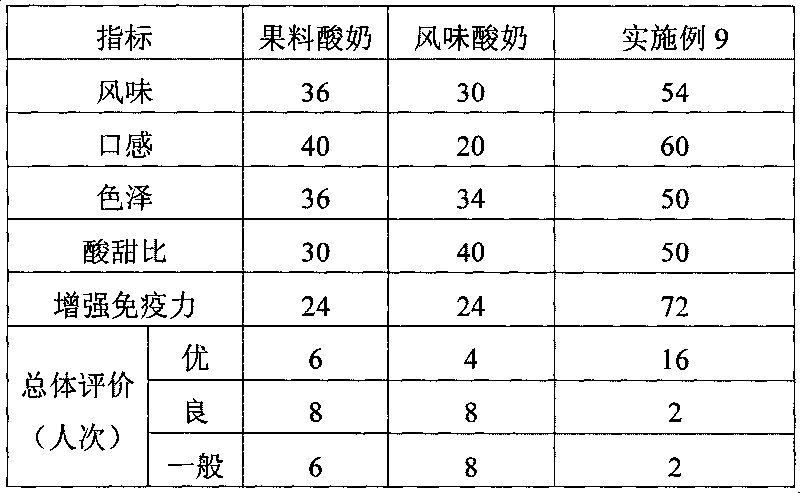

Examples

Embodiment 1

[0034] Embodiment 1 Yogurt Base

[0035] formula

[0036] raw material

Raw material requirements

Amount added

milk

Fat ≥ 4.0%, protein ≥ 3.8%, non-fat milk solids ≥ 11%

68%

sucrose

Total solids ≥ 94%

15%

milk protein powder

Total solids ≥ 94%, protein ≥ 80%

15%

thickener

2%

Lactic acid bacteria

0.4u / Kg

[0037] The preparation process is as follows:

[0038] ①Mix milk, milk protein powder, sucrose and thickener at 30°C;

[0039] ② Homogenize at 30°C and 30MPa pressure;

[0040] ③ Sterilize at 70°C for 30 minutes;

[0041] ④ Cool to 25°C, add lactic acid bacteria;

[0042] ⑤Ferment at 25°C for 10 hours;

[0043] ⑥ Homogenize under 0.8MPa pressure with backup pressure valve;

[0044] ⑦ cooling to 10 ℃ promptly obtains the yoghurt base material of the present invention.

[0045] The test results are as follows:

[0046] project

Embodiment 2

[0047] Embodiment 2 yogurt base

[0048] formula

[0049] raw material

[0050]The preparation process is as follows:

[0051] ①Mix milk, milk protein powder, sucrose and thickener at 40°C;

[0052] ② Homogenize at 40°C and 25MPa pressure;

[0053] ③ Sterilize at 90°C for 10 minutes;

[0054] ④ Cool to 30°C, add lactic acid bacteria and essence;

[0055] ⑤Ferment at 30°C for 9 hours;

[0056] ⑥ Homogenize under 1.0MPa pressure with backup pressure valve;

[0057] ⑦ cooling to 15 ℃ promptly obtains the yoghurt base material of the present invention.

[0058] The test results are as follows:

[0059] project

[0060] project

Embodiment 3

[0061] Embodiment 3 yogurt base

[0062] formula:

[0063] raw material

[0064] The preparation process is as follows:

[0065] ①Mix milk, milk protein powder, aspartame and thickener at 50°C;

[0066] ② Homogenize at 50°C and 25MPa pressure;

[0067] ③ Sterilize at 100°C for 5 minutes;

[0068] ④ Cool to 30°C, add lactic acid bacteria and essence;

[0069] ⑤Ferment at 35°C for 8 hours;

[0070] ⑥ Homogenize under 1.2MPa pressure with backup pressure valve;

[0071] ⑦ cooling to 15 ℃ promptly obtains the yoghurt base material of the present invention.

[0072] The test results are as follows:

[0073] project

[0074] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com