Screw nut with self-locking property and making method

A manufacturing method and nut technology, applied to nuts, threaded fasteners, connecting components, etc., can solve problems such as unreliable fastening effect, increased material consumption, and potential safety hazards, and achieve easy implementation, simple structure, and good economy Effects of benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

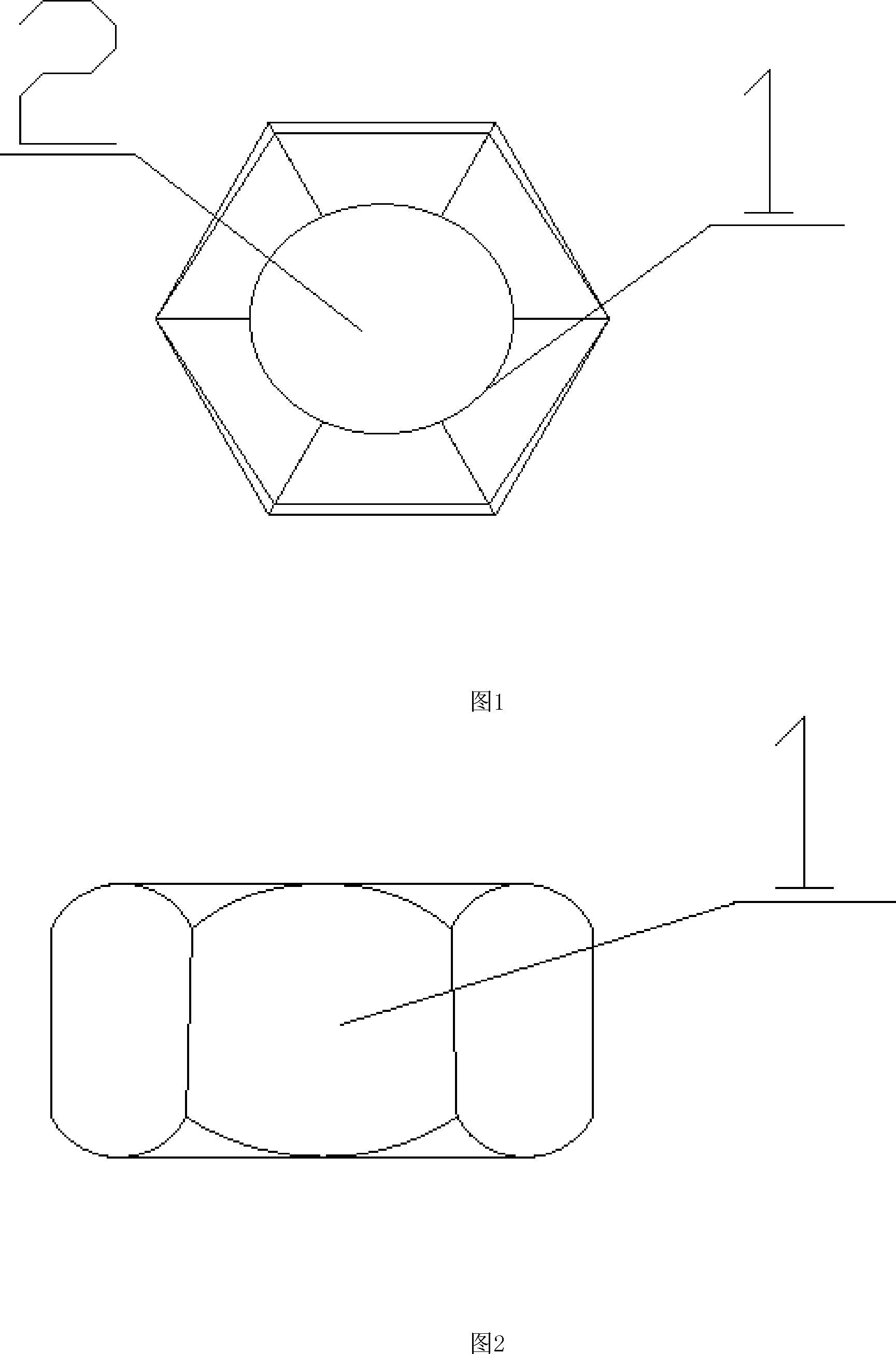

[0011] Embodiment 1: As shown in Figures 1 and 2, the nut 1 is first produced according to the conventional process, and then one end of the nut 1 is extruded by an extrusion method, so that the screw hole 2 of the nut 1 at this end is deformed, and the nut 1 The screw hole 2 of the screw hole becomes circular at one end and oval at the other end, and the screw hole 2 of the nut 1 gradually changes from a circular shape to an oval shape. When reaching the deformed screw hole section of the nut 1, the contact between the nut 1 and the screw will become tighter, causing the elastic deformation of the oval screw hole 2, so that the nut exerts radial pressure on the screw, which will inevitably increase the distance between the screw and the nut thread. The frictional force forms self-locking, so that the nut 1 has connection performance and self-locking performance at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com