Coke-blowhole harshness detecting method

A measurement method and roughness technology, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of missing air holes, small air holes, and low number of air holes.

Inactive Publication Date: 2007-06-13

BAOSHAN IRON & STEEL CO LTD +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the early days of manual analysis, since the distance between the test lines cannot be made very small, a large number of pores with a diameter smaller than the value of the distance may be missed; The probability of interception is smaller

In a limited number of measurements, small pores are often not reflected in the cross-section, making the number of measured pores low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

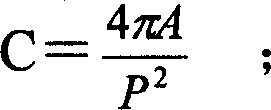

[0043] The cold strength (DI 150 15 ) and pore roughness, the results are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

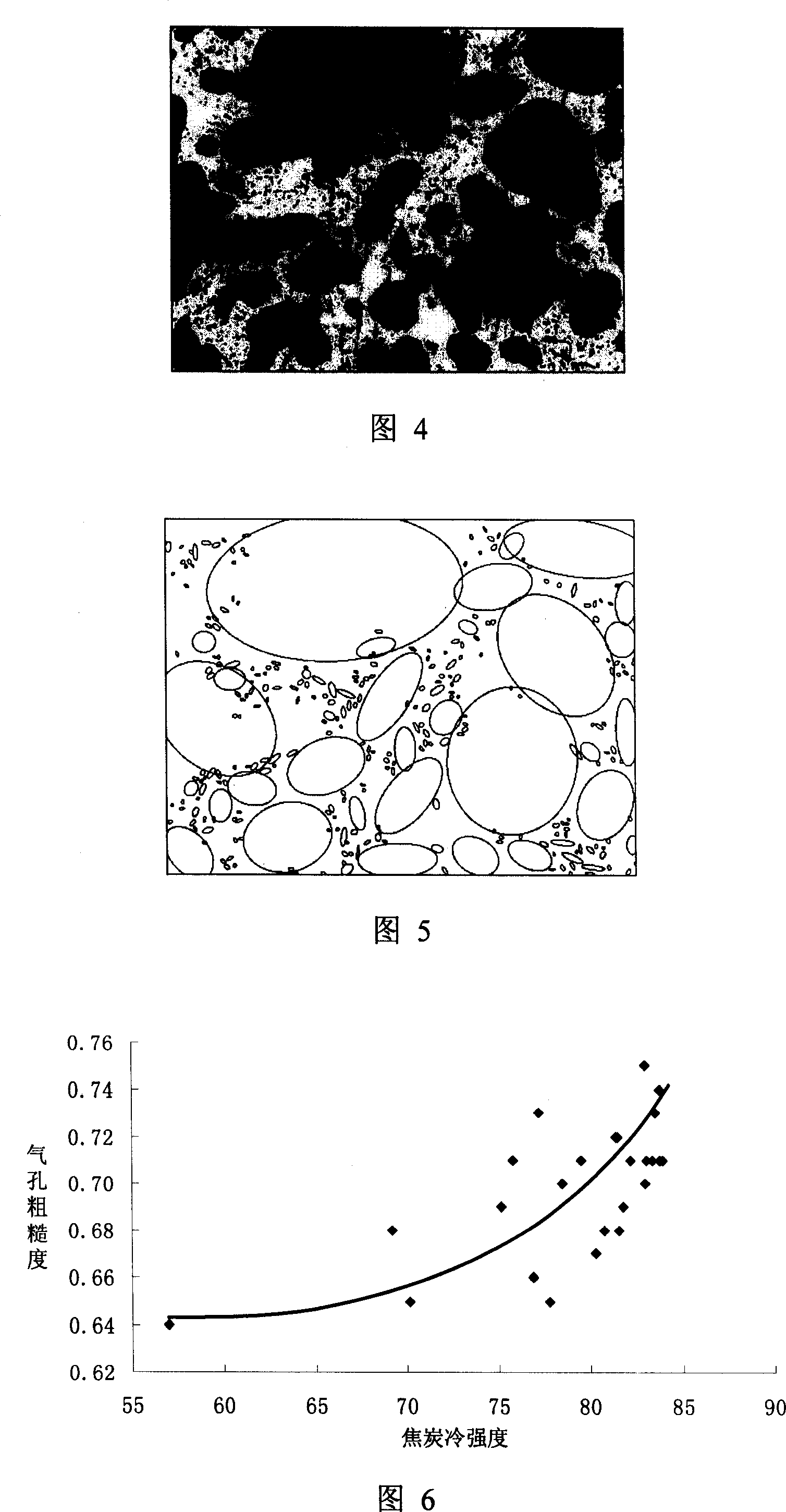

The invention discloses a measuring method for coke air cavity roughness. It includes the following steps: sampling, capturing grey scale image of coke 2D section on computer that has optical microscope with digital output, transforming the image to black and white two value image and taking adjusting to fault air cavity and broken air cavity wall, measuring and calculating the area A and circumference P of every air cavity and the roundness C, fitting a ellipse for every air cavity and calculating roundness, the air cavity roughness is the ratio of the two value, calculating roughness of all the air cavities and calculating mean value that is the coke air cavity roughness. The invention would take effective prejudgment to intensive property of blast furnace using coke.

Description

(1) Technical field [0001] The invention relates to a method for measuring the pore roughness of coke, and belongs to the technical field of charcoal phases applied in coking. (2) Background technology [0002] In traditional ironmaking production, one of the main functions of coke in the blast furnace is as the skeleton of the material column, so the strength has become one of the important parameters to evaluate the performance of blast furnace coke. As a porous coke, its pore structure is closely related to its strength. The relationship between structure and performance has important practical significance for guiding actual production, especially coal blending. However, in the field of blast furnace coke, although some research has been done on the pore structure characteristics of coke, parameters such as porosity, average pore diameter (size), pore wall thickness, and pore deformation have been set, but the relationship between these parameters and coke properties has...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B21/30G01B11/30

Inventor 吴信慈杨俊和胡德生房永征曹银平金宝沈风雷徐志栋

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com