Lithium-contained composite metal oxide material of lamina structure and use thereof

A composite metal, layered structure technology, applied in the field of materials, can solve problems such as layered compounds that have not yet been coated with carbon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

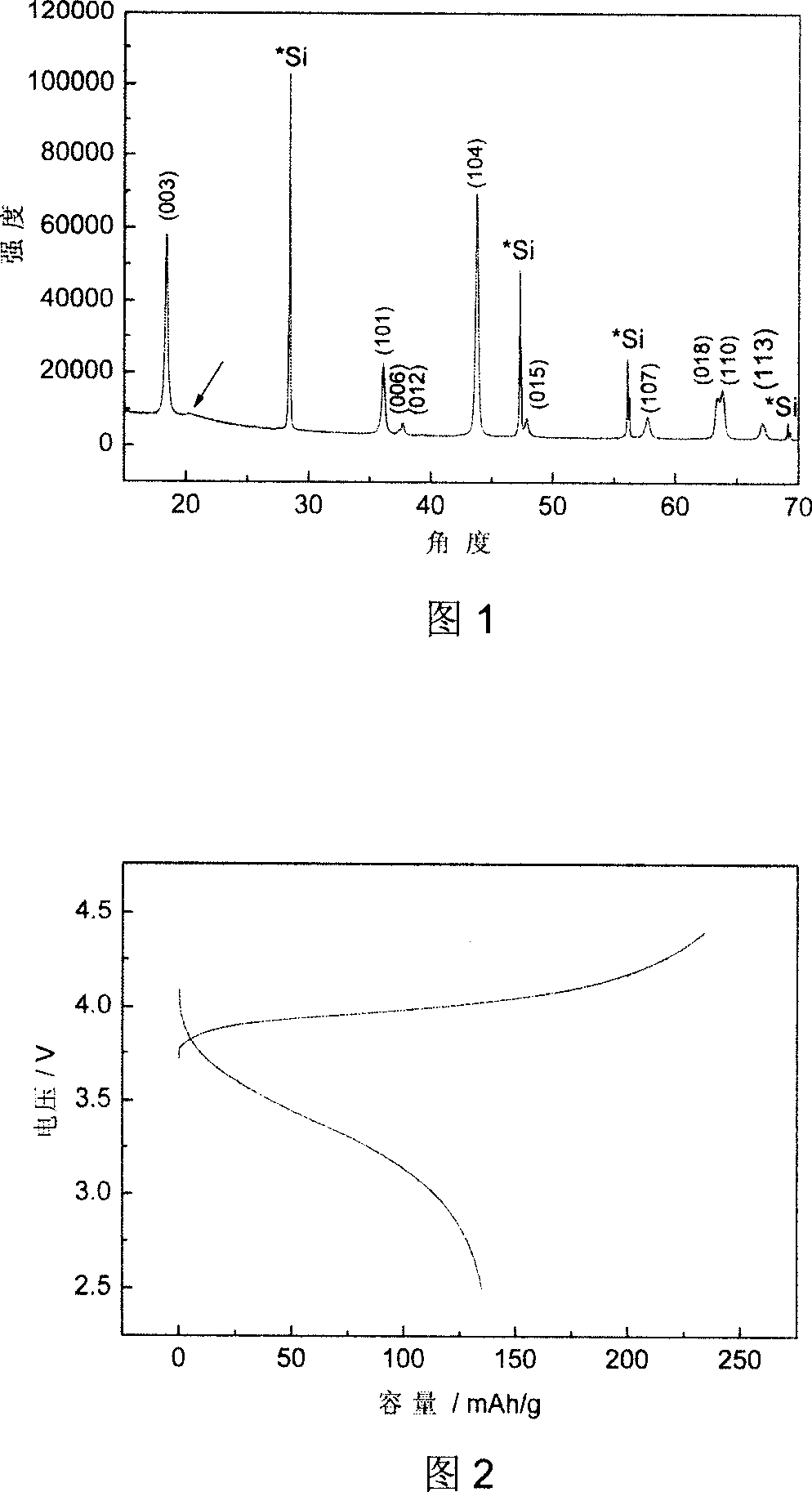

Embodiment 1

[0043] 0.02mol Cr(NO 3 ) 3 9H 2 O, 0.1267mol CH 3 COOLi·2H 2 O and 0.0533mol Si(OC 2 h 5 ) 4 dissolved in appropriate amount of CH 3 CH 2 OH, slowly add NH 3 ·H 2 O, adjust the pH of the solution to 9.5-10.5, let it stand still to form a gel, place it in an oven at 100° C. for 10 hours to evaporate the solvent to dryness, and obtain a precursor. The precursor was mechanically ball milled for 4 hours, heated at 400°C for 10 hours under Ar gas, then mechanically ball milled for 4 hours after cooling down, and kept at 900°C for 10 hours to obtain Li[Cr 0.2 Li 0.267 Si 0.533 ]O 2 .

[0044] Will get Li[Cr 0.2 Li 0.267 Si 0.533 ]O 2 Mix with acetylene black and 10% polyvinylidene fluoride (PVDF) nitrogen methyl pyrrolidone solution at normal temperature and pressure to form a slurry (active material: acetylene black: PVDF = 90:5:5), and evenly coat it on the aluminum foil lining After drying in vacuum at 100°C for 5 hours, the resulting film was pressed under a p...

Embodiment 2

[0048] 0.01mol Cr 2 o 3 , 0.1267mol LiOH 2H 2 O and 0.0533mol SiO 2 The precursor was obtained by mixing mechanical ball milling for 4 hours, and then kept at 900 °C under Ar gas for 10 hours to obtain Li[Cr 0.2 Li 0.267 Si 0.533 ]O 2 . Electrodes and test cells were prepared in the same manner as in Example 1. Its electrochemical performance testing method is the same as that of Example 1, and the results are shown in Table 1.

Embodiment 3

[0050] With 0.04mol Cr(NO 3 ) 3 9H 2 O, 0.12mol CH 3 COOLi·2H 2 O and 0.04mol Si(OC 2 h 5 ) 4 For reactant, according to the same conditions of embodiment 1, Li[Cr 0.4 Li 0.2 Si 0.4 ]O 2 . Its electrochemical performance testing method is the same as that of Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap