Heat pipe for absorption refrigerating machine

A technology for absorption refrigerators and heat transfer tubes, which is applied in the direction of adsorption machines, refrigerators, heat transfer modification, etc., and can solve the problems of reduced heat transfer efficiency of heat transfer tubes and the inability to form rough surfaces finely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

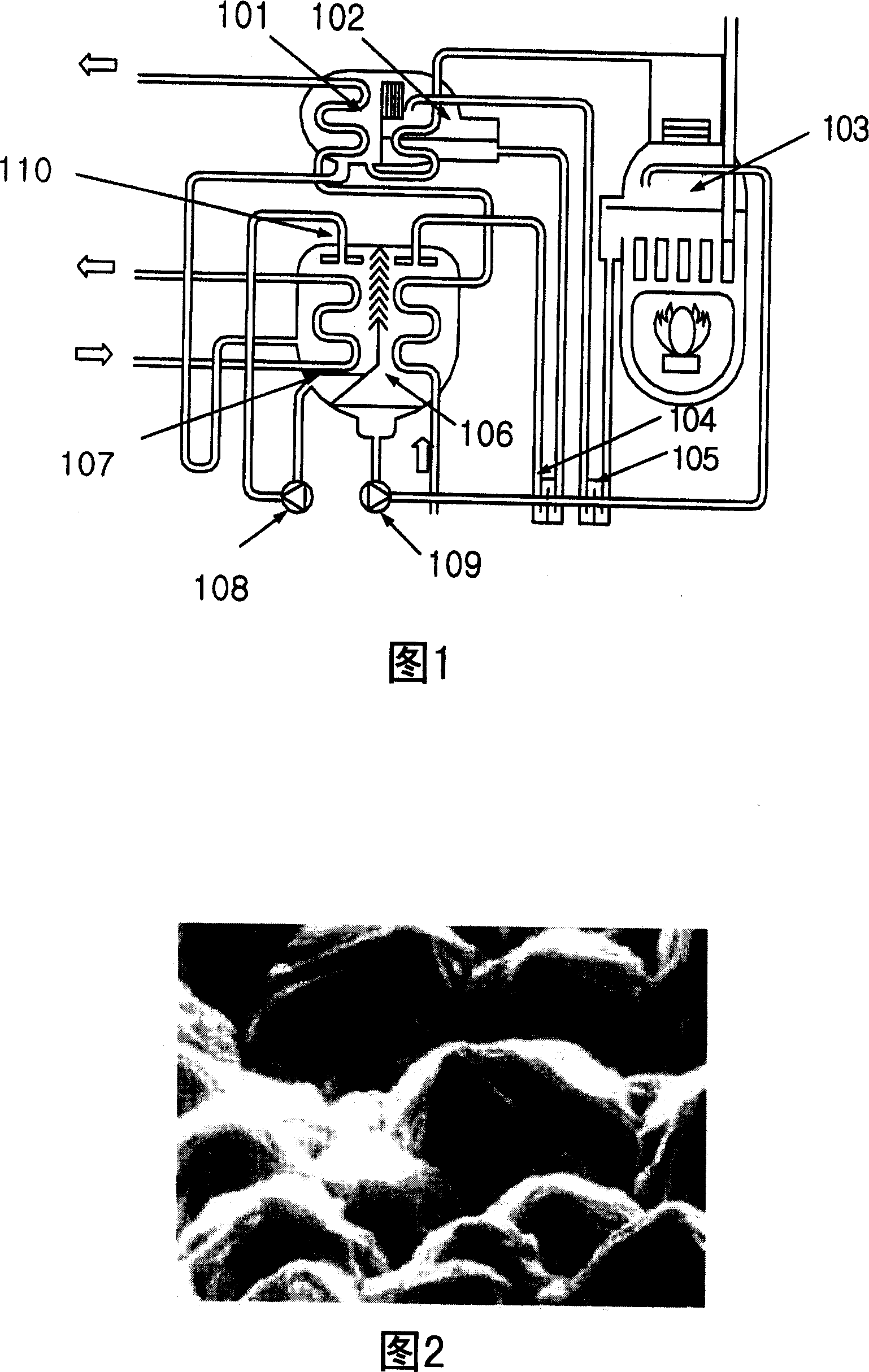

[0013] Hereinafter, a heat transfer tube for an absorption refrigerator according to an embodiment of the present invention will be described in detail with reference to the drawings.

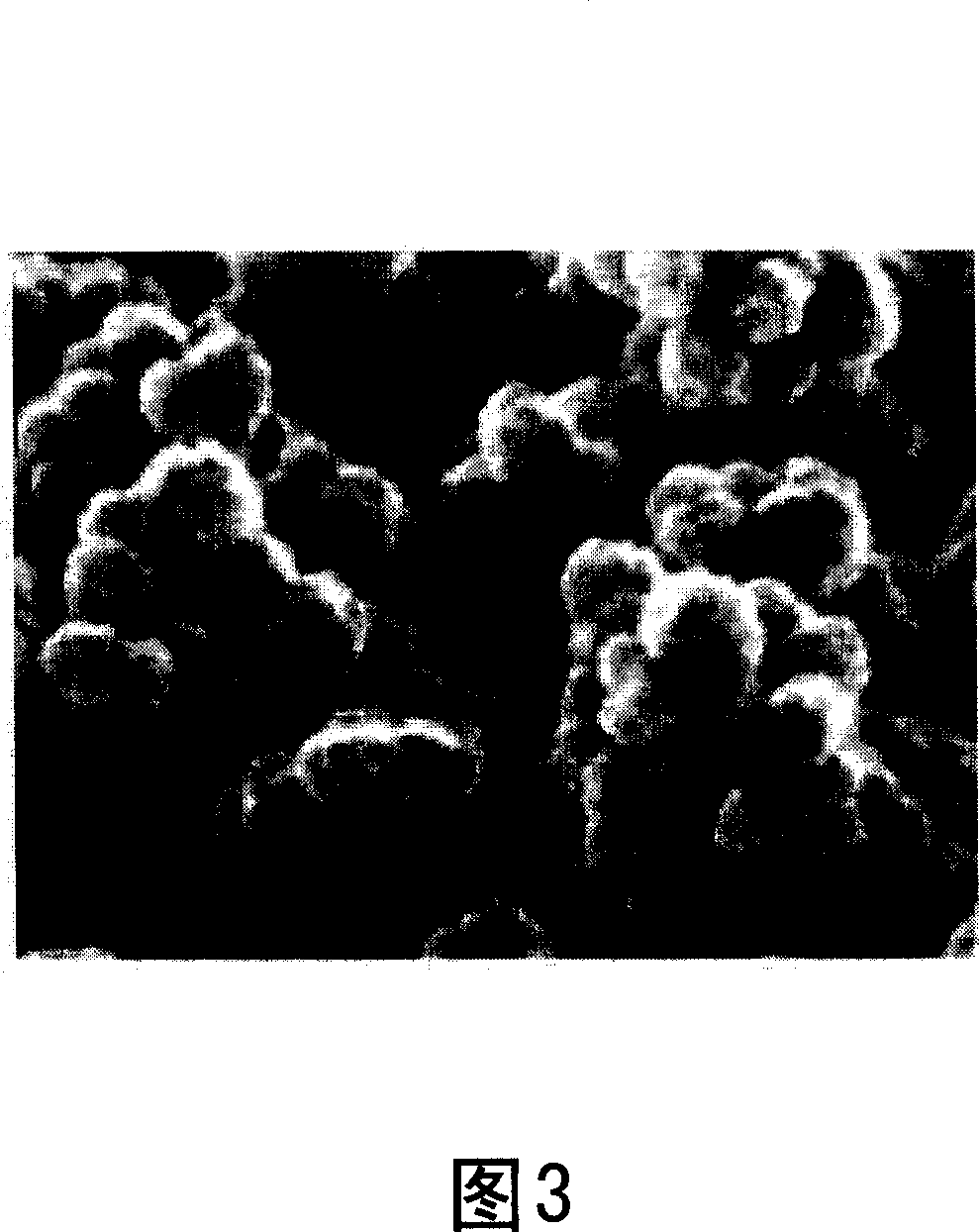

[0014] Fig. 2 is an enlarged view showing the surface of a heat transfer tube in which fine protrusions are formed by an electroplating process according to an embodiment of the present invention.

[0015] In this embodiment, the constituent elements constituting the absorption refrigerator, for example, both the inner surface and the outer surface of the heat transfer tubes used in the evaporator (107), absorber (106), condenser (101), etc., Or copper (Cu) is electroplated only on any one of the inner surface and the outer surface, thereby forming fine protrusions as shown in FIG. 2 .

[0016] In this electroplating method, copper cyanide (CuCN) electroplating method, copper sulfate (CuSO 4 ) electroplating method, etc. In particular, copper cyanide plating is preferably employed. The compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap