Compound physical field reinforced membrane separation process

A separation process and membrane strengthening technology, applied in the field of membrane separation, to achieve the effect of improving membrane retention rate, high separation efficiency, and inhibiting membrane flux attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

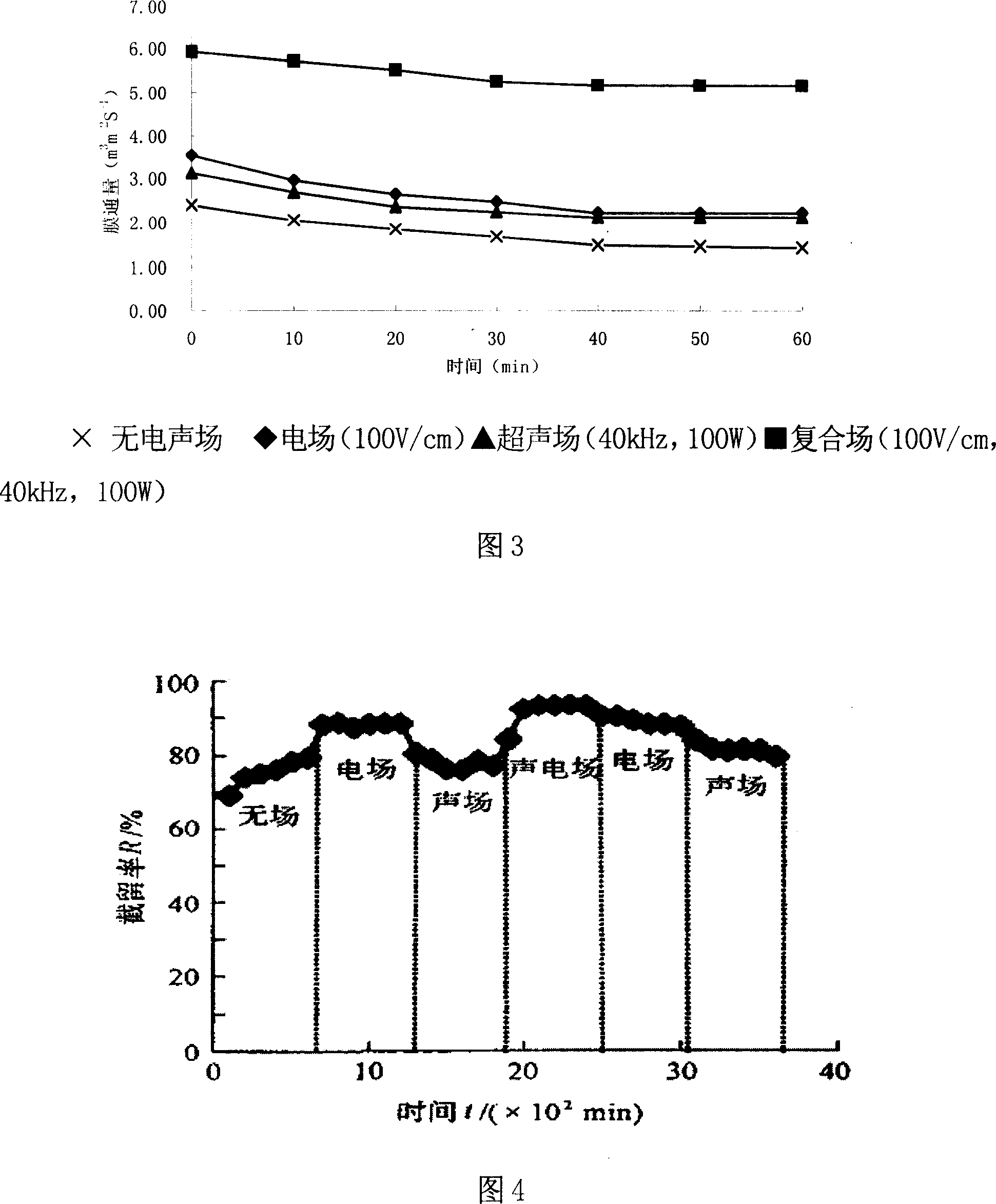

[0037] (1) Stir the treatment solution at a speed of 60 rpm, the treatment solution is mucopolysaccharide w=0.5%, and keep the temperature at 30° C. for 30 minutes;

[0038] (2) Fully open the ultrafiltration backflow valve, start the peristaltic pump, the flow rate of the treatment liquid is 300mL / min and reach a constant value, and make the pressure difference between the inside and outside of the ultrafiltration membrane zero, even if the whole system reaches a full backflow state;

[0039] (3) Slowly close the backflow valve to gradually increase the pressure difference between the inlet and outlet of the membrane separation system to 0.1MPa, and maintain a constant pressure difference between the inside and outside of the membrane;

[0040] (4) In the dynamic membrane separation system, applying an electric field strength of 100V / cm to a DC electric field and a power of 100W and an ultrasonic field with a frequency of 40KHz selects the negatively charged sodium polyacrylat...

Embodiment 2

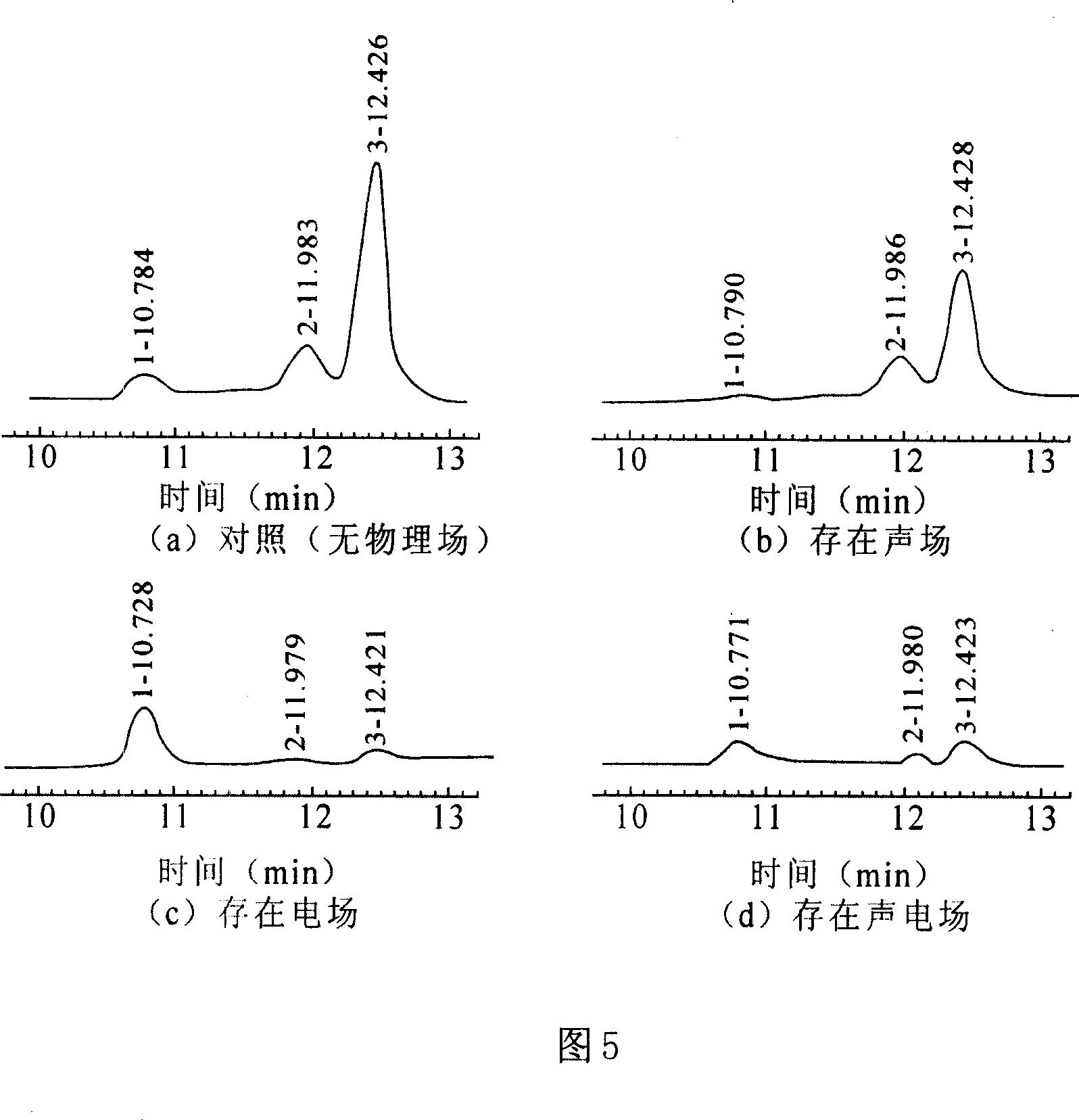

[0054] Influence of Compound Physical Fields on Membrane Flux Decay

[0055] The degree of membrane flux attenuation (m) refers to the decrease in membrane flux over time due to concentration polarization, membrane compaction, and membrane pore clogging during the ultrafiltration process. By measuring the pure water membrane flux J before and after the membrane treatment solution o and J t Calculated, it can be expressed by the following formula:

[0056] m = J o - J t J o × 100 %

[0057] Using PES300 membrane and charged PES300 membrane, under the conditions of 0.2MPa, flow rate of 300mL / min, and electric field strength of 100V / cm, the separation experiment of 0.5% dextran sulfate was carried out respectively, and the combined effects of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap