Untwisted yarn fabric and its production process

A production process, a technology of untwisted yarn, applied in the direction of yarn, textiles and papermaking, can solve the problems of inability to ensure the softness and fullness of the cloth surface, difficult weaving of textiles, reduced yarn strength, etc., to increase the fluffy feeling and coverage factor, The effect of improving dye uptake and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

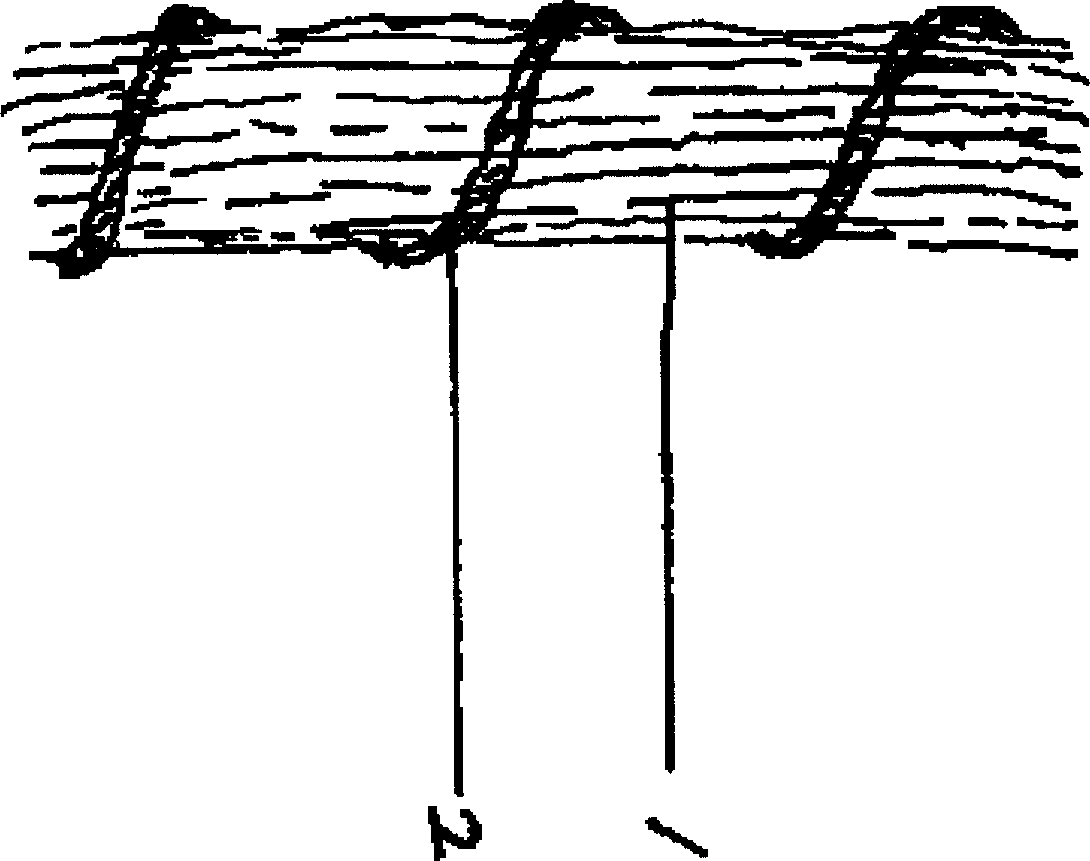

[0017] Embodiment 1: While spinning single yarn (1), spin water-soluble vinylon yarn (2) of 60-100 English counts, twist and spin 30-50 British counts of untwisted yarns on the twisting machine after doubling Yarn. Its process flow: single yarn - cleaning - carding - drawing (2 roads) - roving - spun yarn - winding; water-soluble vinylon - cleaning - carding - drawing (2 roads) - roving - spun yarn - Winding; then two single yarns are paralleled-twisted-winded into yarn.

Embodiment 2

[0018] Example 2: After spinning untwisted pure cotton single yarn (1), use 97-58dexV water-soluble vinylon filament (2) as a finished product, and then twist and spin a qualified product on a twisting machine through doubling. The process Process: single yarn - cleaning - carding - drawing (2 passes) - roving - spun yarn - winding; use 97 ~ 58dtex water-soluble vinylon filament (2), and then two single yarns are paralleled - twisted - winding Tube into yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com