Multilayer composite floorboard

A multi-layer composite and floor technology, applied in the direction of floor, building, building structure, etc., can solve the problems of lack of solid wood floor effect, easy to be worn, loud sound, etc., to achieve good stability and noise reduction effect, convenient laying, good pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

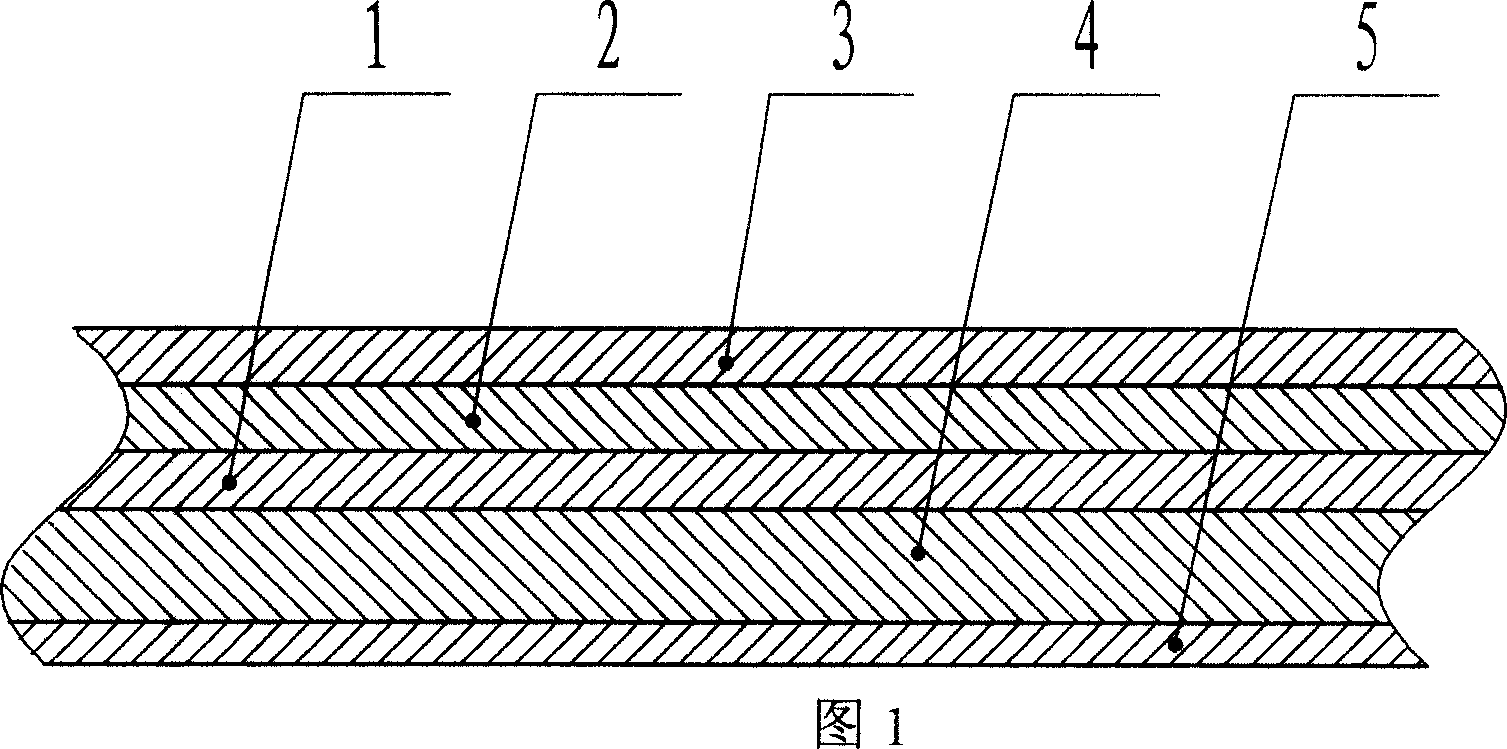

[0011] As shown in Figure 1, a multi-layer composite floor includes a plastic base layer 1, a printing layer 2 and a wear-resistant layer 3 arranged on the plastic base layer 1, and a layer of high-density board layer is pasted below the plastic base layer 1 4. A waterproof layer 5 is also coated under the high-density board layer 4 . Since the plastic floor and the high-density board are used for compounding, the composite board not only has good formability, but also has a certain rigid style of the wooden floor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com