Mechanical weed seed management system

a technology of weed seed management and mechanical parts, applied in the direction of mowers, agriculture tools and machines, agriculture, etc., can solve the problems of increasing the ineffectiveness of chemical control of weeds, reducing the effectiveness of weed control, and reducing the yield of weeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

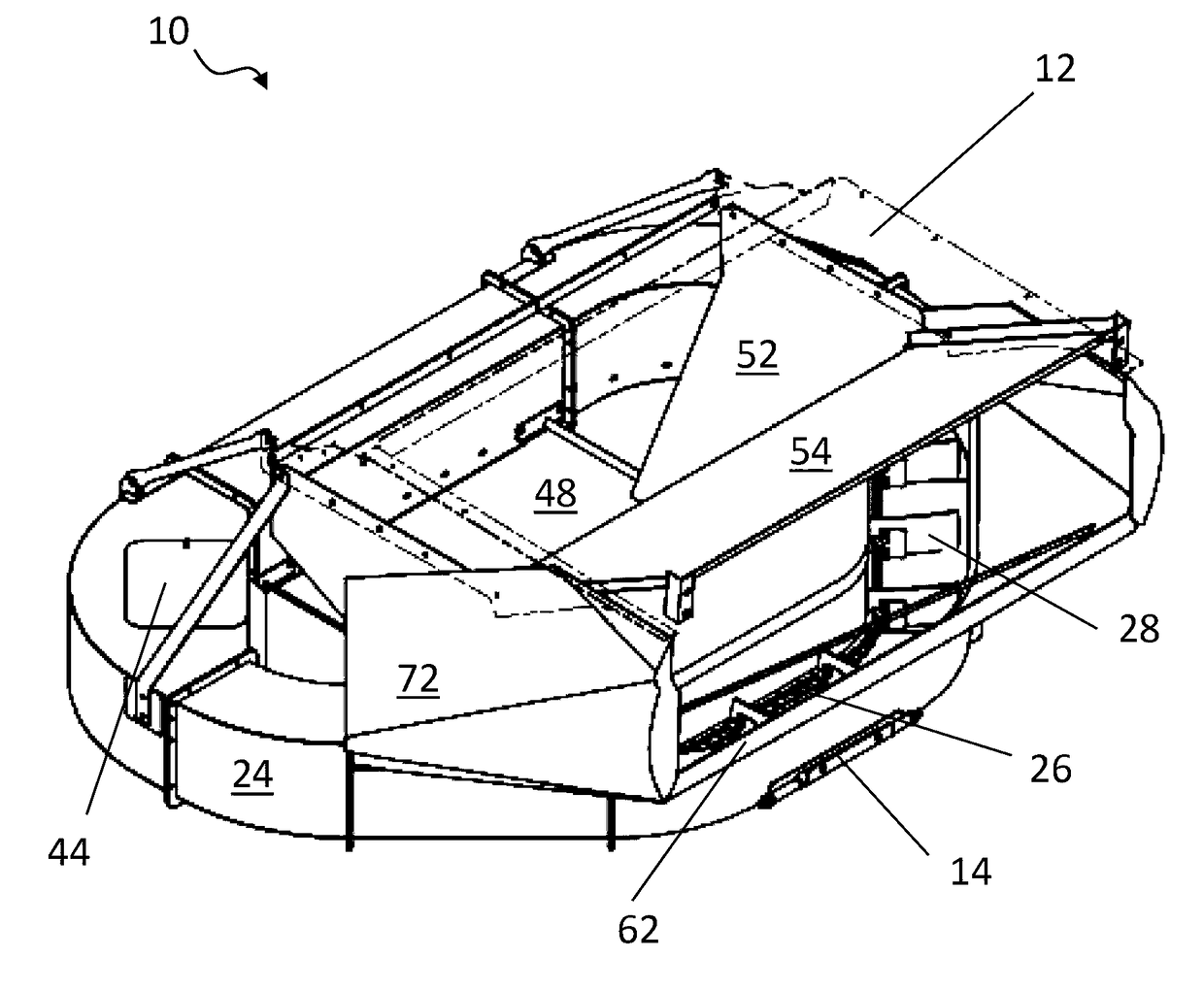

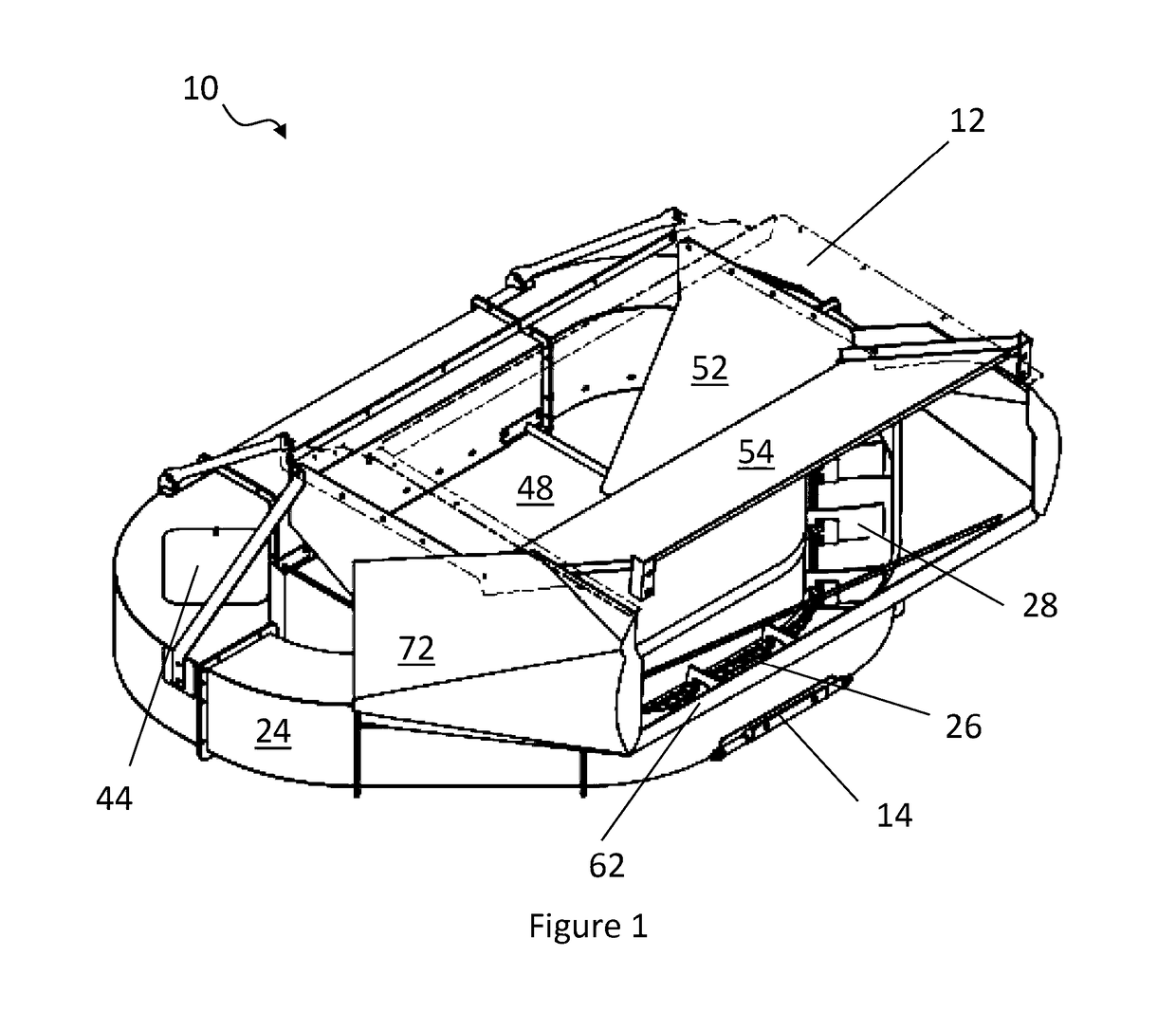

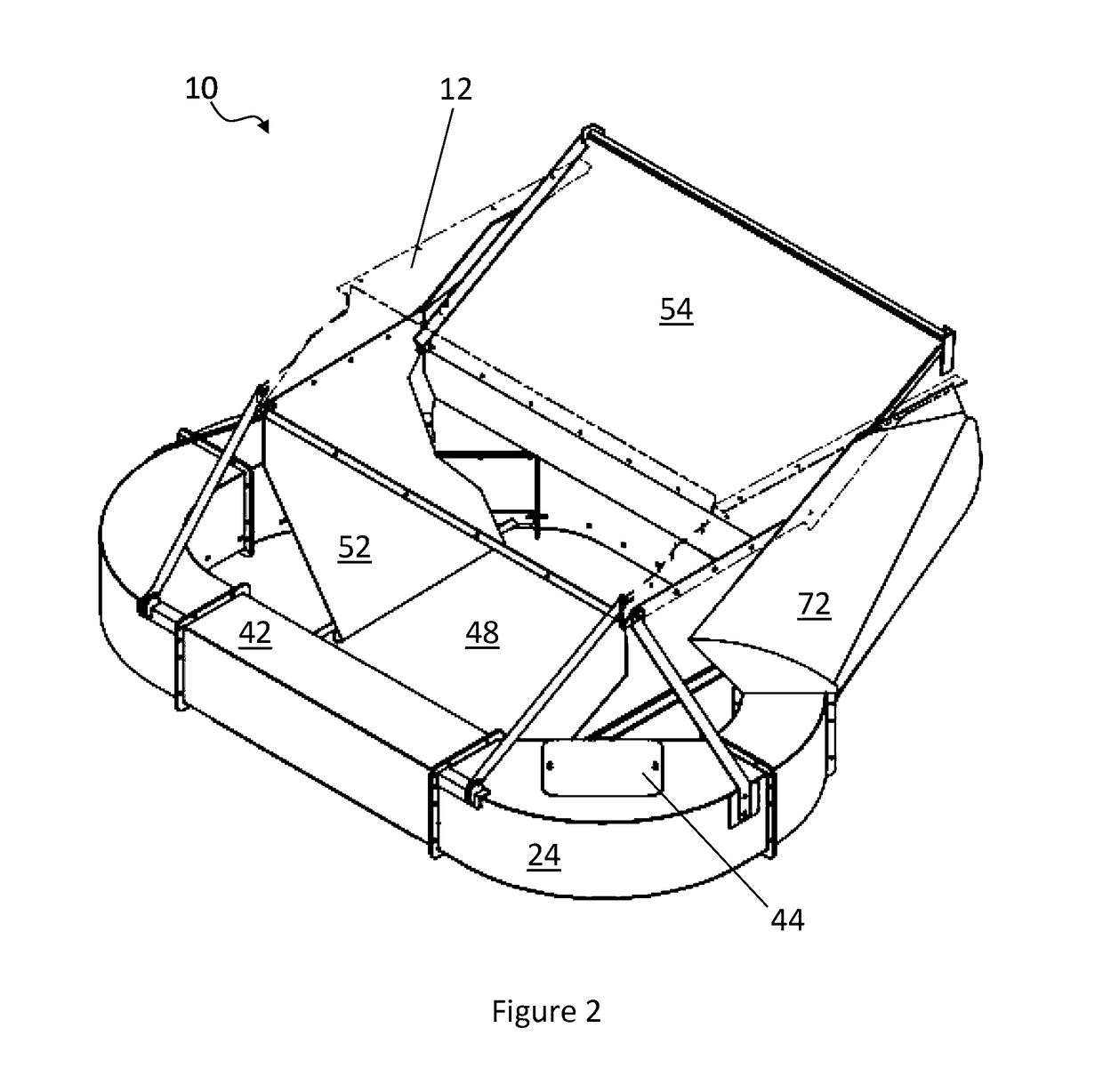

[0037]Referring to the Figures, there is shown a device 10 of a mechanical weed seed management system for use with and upon a harvester 12. The device 10 is mounted upon the harvester 12 so as to catch and process waste material, such as weed and straw, from the harvesting process. Accordingly, the device 10 is generally mounted toward the rear of the harvester 12.

[0038]The trough 24 of the device 10 is annular and generally rounded-triangular in shape (as best seen in FIG. 3), encircling the back of the harvester 12 and reaching to an underside of the harvester 12. The trough 24 comprises at least three walls defining a volume therein of a depth greater than 150 mm, preferably about 310 mm deep. The width of the trough is between about 250 mm and 450 mm, preferably between 275 mm and 290 mm. Within the trough 24 is disposed a chain 26 comprising paddles 28 spaced apart on links of the chain 26. The height of each paddle 28 is complementary to the depth of the trough 24; similarly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com