Miniature telephoto lens assembly

a miniature telephoto lens and lens assembly technology, applied in the field of miniature telephoto lens assembly, can solve the problems of insufficient ttl/efl (effective focal length ratio) and insufficient conventional lens assembly comprising four lens elements for good quality imaging in such devices, and achieve the effects of reducing chromatic aberration, reducing ttl of lens system, and negatively affecting lens manufacturability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

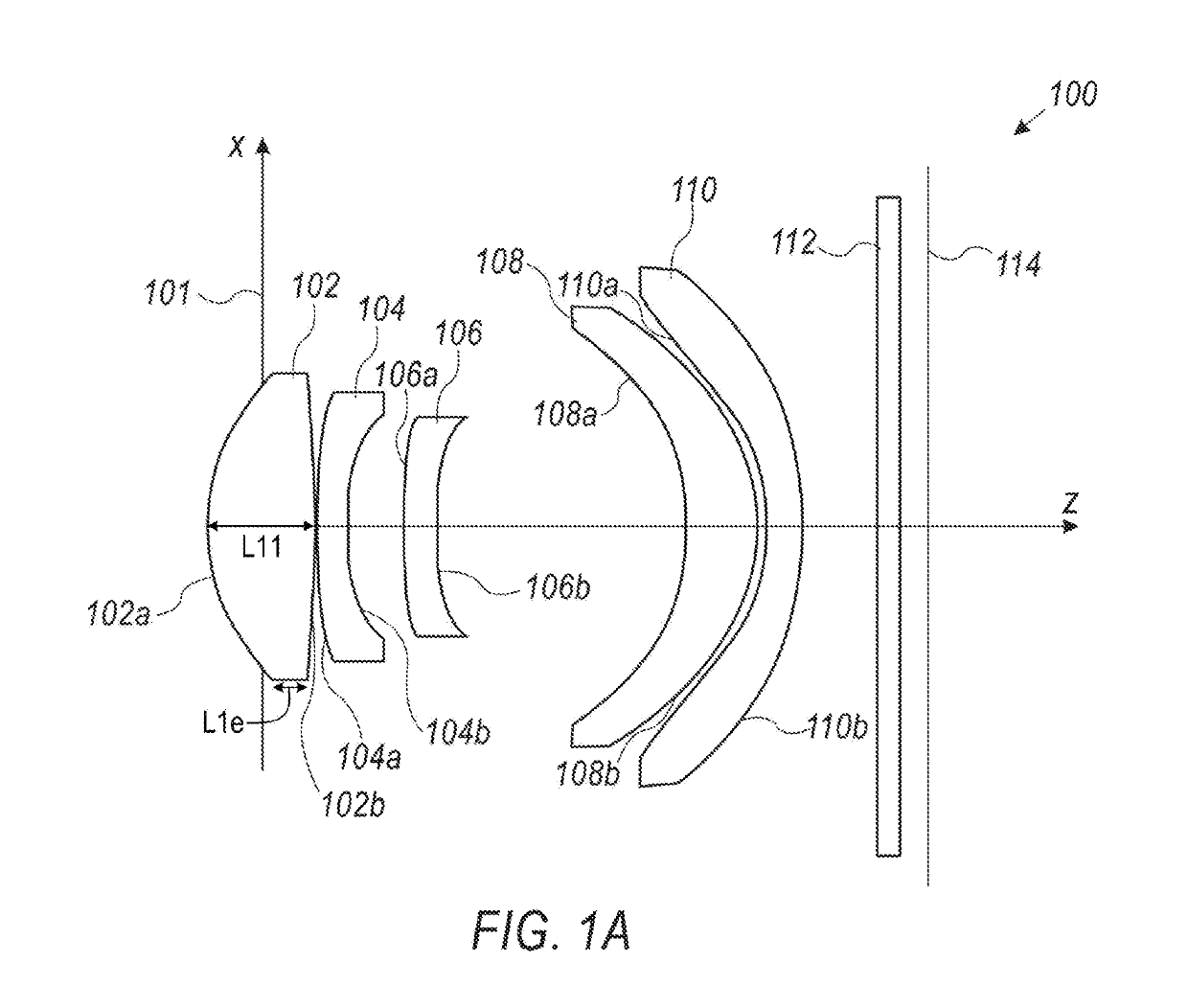

embodiment 100

[0021]In embodiment 100, all lens element surfaces are aspheric. Detailed optical data is given in Table 1, and the aspheric surface data is given in Table 2, wherein the units of the radius of curvature (R), lens element thickness and / or distances between elements along the optical axis and diameter are expressed in mm. “Nd” is the refraction index. The equation of the aspheric surface profiles is expressed by:

[0022]z=cr21+1-(1+k)c2r2+α1r2+α2r4+α3r6+α4r8+α5r10+α6r12+α7r14

where r is distance from (and perpendicular to) the optical axis, k is the conic coefficient, c=1 / R where R is the radius of curvature, and a are coefficients given in Table 2. In the equation above as applied to embodiments of a lens assembly disclosed herein, coefficients α1 and α7 are zero. Note that the maximum value of r “max r”=Diameter / 2. Also note that Table 1 (and in Tables 3 and 5 below), the distances between various elements (and / or surfaces) are marked “Lmn” (where m refers to the lens element...

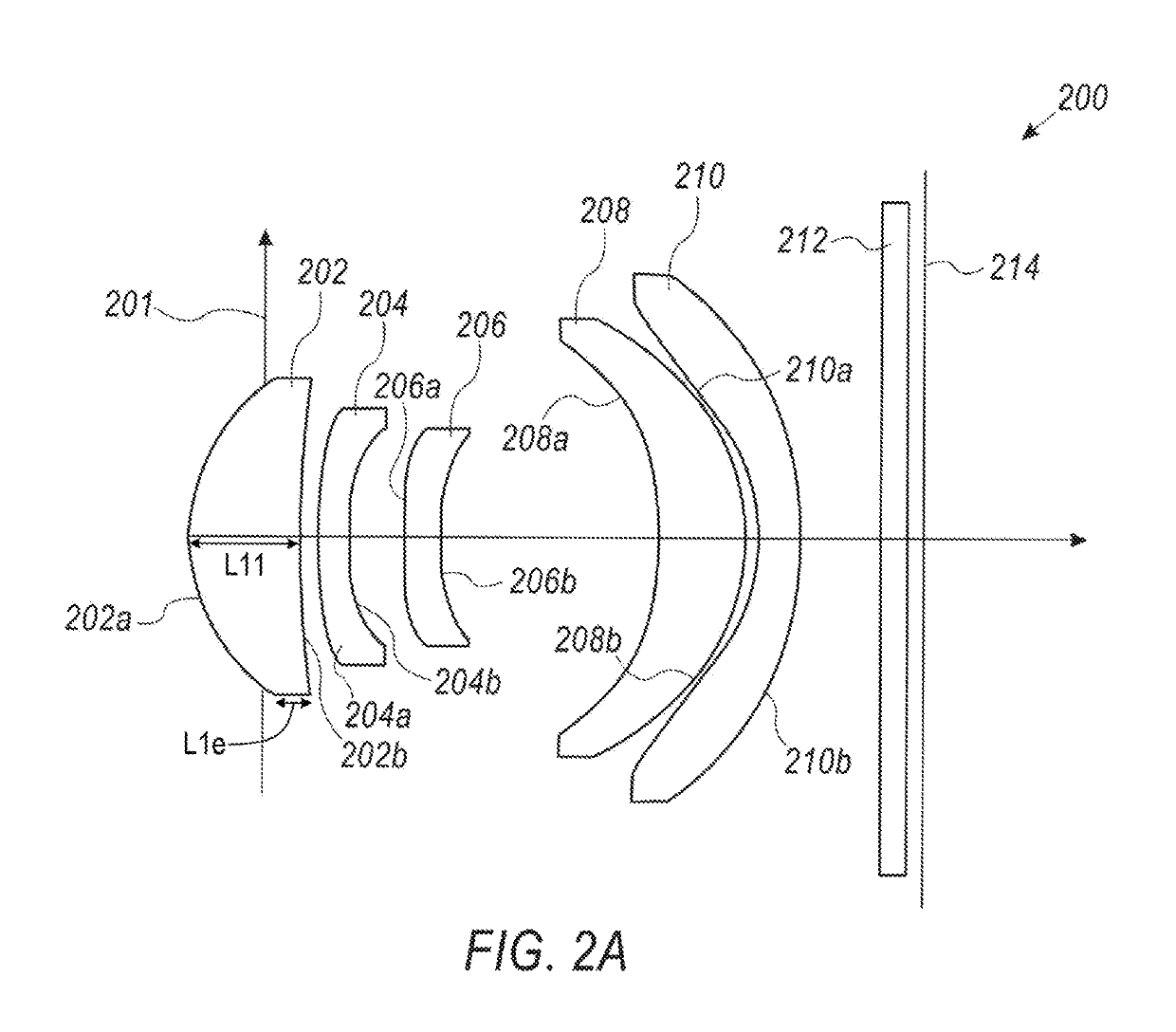

embodiment 200

Embodiment 200 provides a FOV of 43.48 degrees, with EFL=7 mm, F#=2.86 and TTL=5.90 mm. Thus and advantageously, the ratio TTL / EFL=0.843. Advantageously, the Abbe number of the first, third and fifth lens elements is 56.18. The first air gap between lens elements 202 and 204 has a thickness (0.129 mm) which is about half the thickness d2 (0.251 mm). Advantageously, the Abbe number of the second lens element is 20.65 and of the fourth lens element is 23.35. Advantageously, the third air gap between lens elements 206 and 208 has a thickness (1.766 mm) greater than TTL / 5 (5.904 / 5 mm). Advantageously, the fourth air gap between lens elements 208 and 210 has a thickness (0.106 mm) which is less than 1.5×d5 (0.495 mm).

[0031]The focal length (in mm) of each lens element in embodiment 200 is as follows: f1=2.851, f2=−5.468, f3=−10.279, f4=7.368 and f5=−4.536. The condition 1.2×|f3|>|f2|5.468>1.5×2.851. f1 also fulfills the condition f1

[0032]Using the data from row #2 ...

embodiment 300

[0034]In embodiment 300, all lens element surfaces are aspheric. Detailed optical data is given in Table 5, and the aspheric surface data is given in Table 6, wherein the markings and units are the same as in, respectively, Tables 1 and 2. The equation of the aspheric surface profiles is the same as for embodiments 100 and 200.

[0035]

TABLE 5Radius RDistancesDiameter#Comment[mm][mm]Nd / Vd[mm]1StopInfinite−0.382.42L111.51270.9191.5148 / 63.12.53L12−13.38310.0292.34L218.44110.2541.63549 / 23.912.15L222.61810.4261.86L31−17.96180.265 1.5345 / 57.091.87L324.58411.9981.78L41−2.88270.5141.63549 / 23.913.49L42−1.97710.1213.710L51−1.86650.431 1.5345 / 57.094.011L52−6.36700.5384.412WindowInfinite0.210 1.5168 / 64.173.013Infinite0.2003.0

[0036]

TABLE 6Conic#coefficient kα2α3α4α5α62−0.5341.3253E−022.3699E−02−2.8501E−021.7853E−02−4.0314E−033−13.4733.0077E−024.7972E−031.4475E−02−1.8490E−024.3565E−034−10.1327.0372E−041.1328E−011.2346E−03−4.2655E−028.8625E−0355.180−1.9210E−032.3799E−01−8.8055E−022.1447E−01−1.2702E−...

PUM

| Property | Measurement | Unit |

|---|---|---|

| focal length f1 | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com