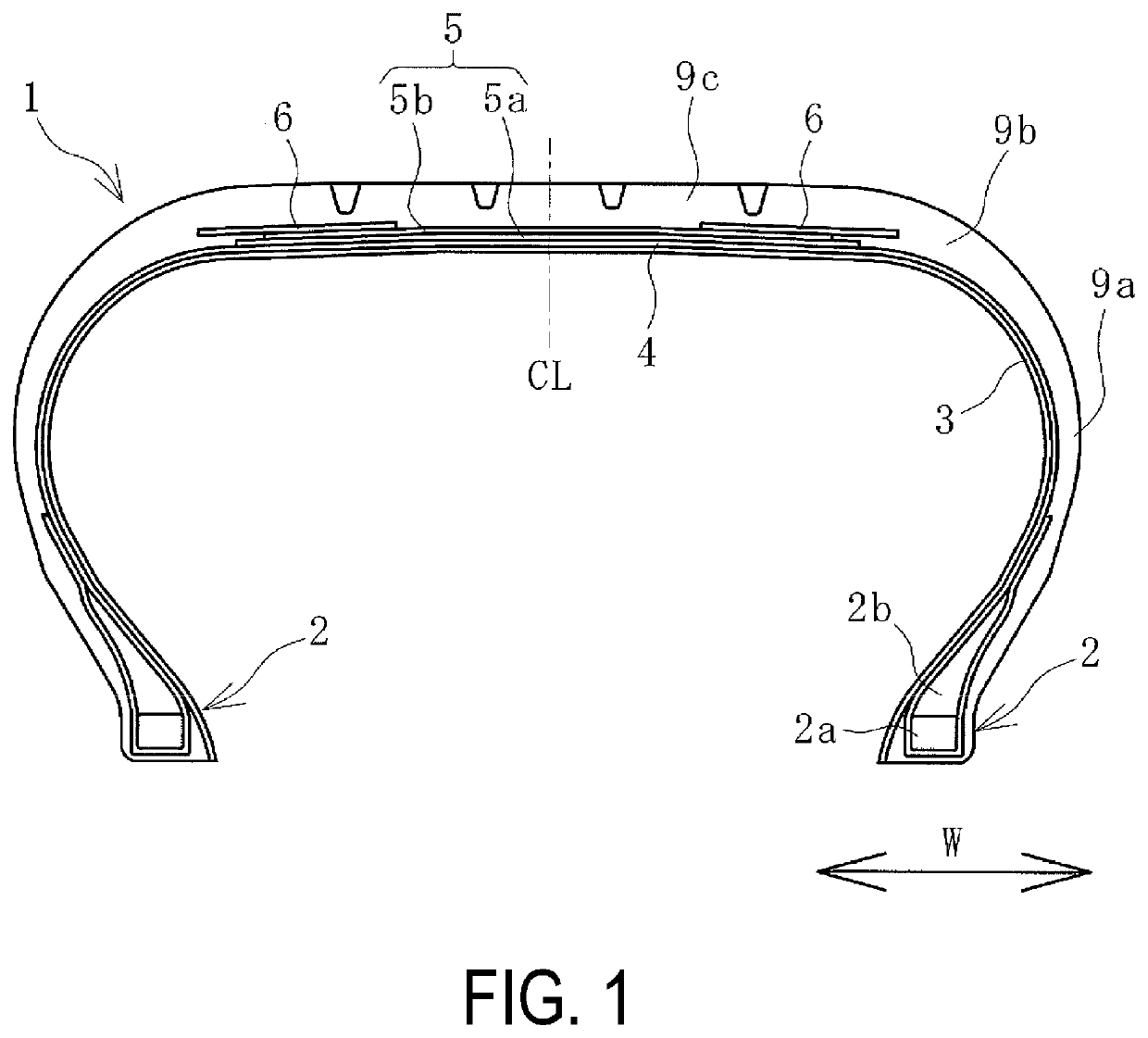

Pneumatic tire and method for manufacturing the same

a technology of pneumatic tires and pneumatic reinforcement layers, which is applied in the field of pneumatic tires, can solve problems such as uniformity degradation of tires, and achieve the effects of reducing road noise at a high level, avoiding the defect of tire uniformity degrading caused by belt reinforcing layers, and enhancing high-speed durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

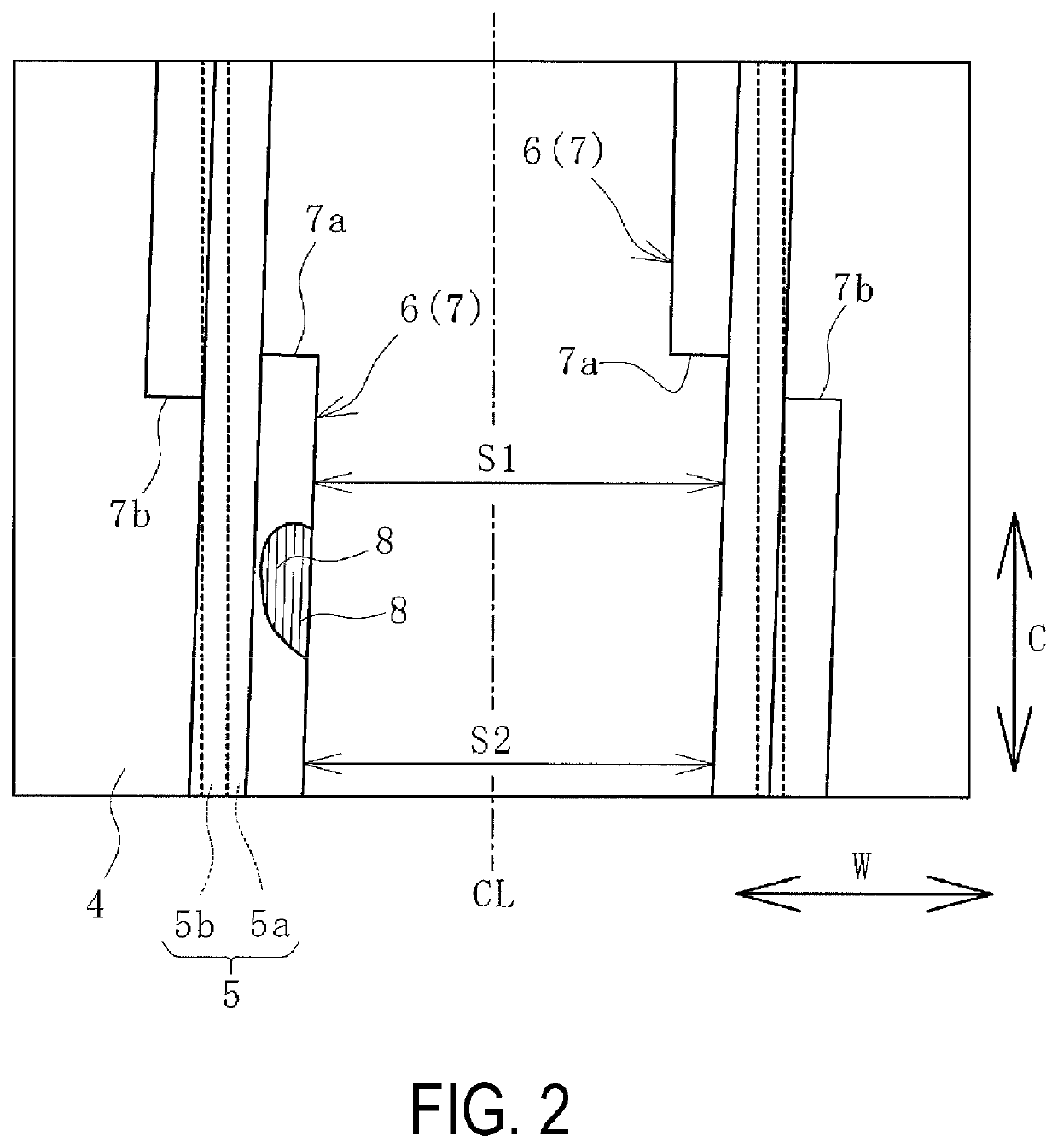

[0041]Using two types of test tires (Working Example and Conventional Example), that is, pneumatic tires for a passenger vehicle having identical specifications where only an embedding specification of the belt reinforcing layers differed, Radial Force Variation (RFV) and Radial Run Out (RRO) were measured and the results thereof are shown in Table 1. In Table 1, measurement values of the Examples are indexed, a measurement value of the Conventional Example being a reference at 100. Smaller index numbers indicate superior uniformity of the tire.

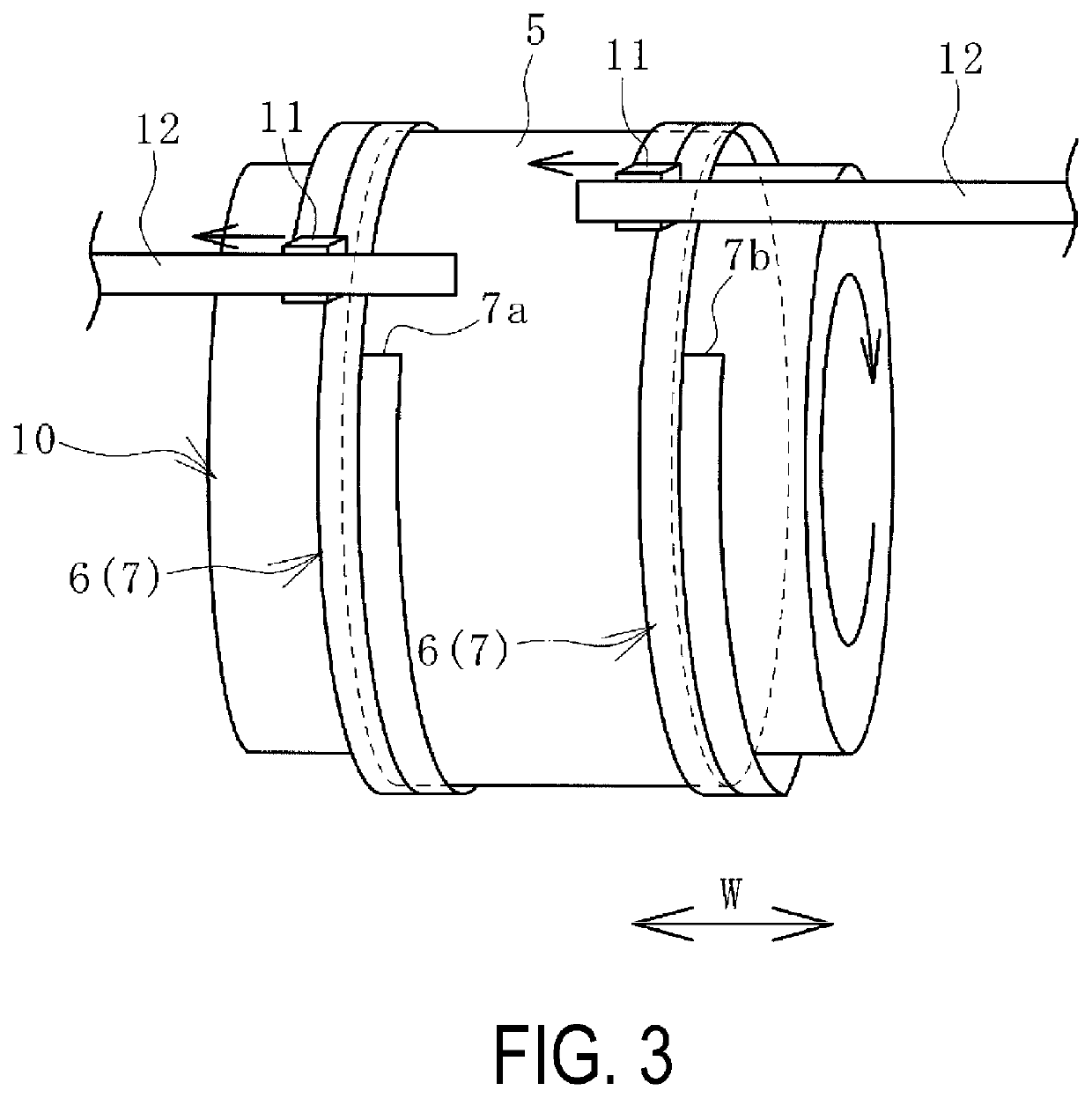

[0042]As illustrated in FIG. 2, the tire width direction gaps S1 and S2 between the belt reinforcing layers of the Working Example were substantially the same along the tire circumferential direction. The longitudinal direction edges positioned at the center portion side of the tire width direction of the left and right strip members were set at substantially the same positions along the tire circumferential direction. As illustrated in FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| durability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com