Triple-lock main tee splice

a technology of end connectors and tees, which is applied in the direction of ceilings, building components, constructions, etc., can solve the problems of affecting the service life of the end connector, the smooth engagement and coupling between the end connectors can be obstructed, and the performance of the end connectors is marginal at best, so as to improve the service life, increase the tensile capacity, and increase the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

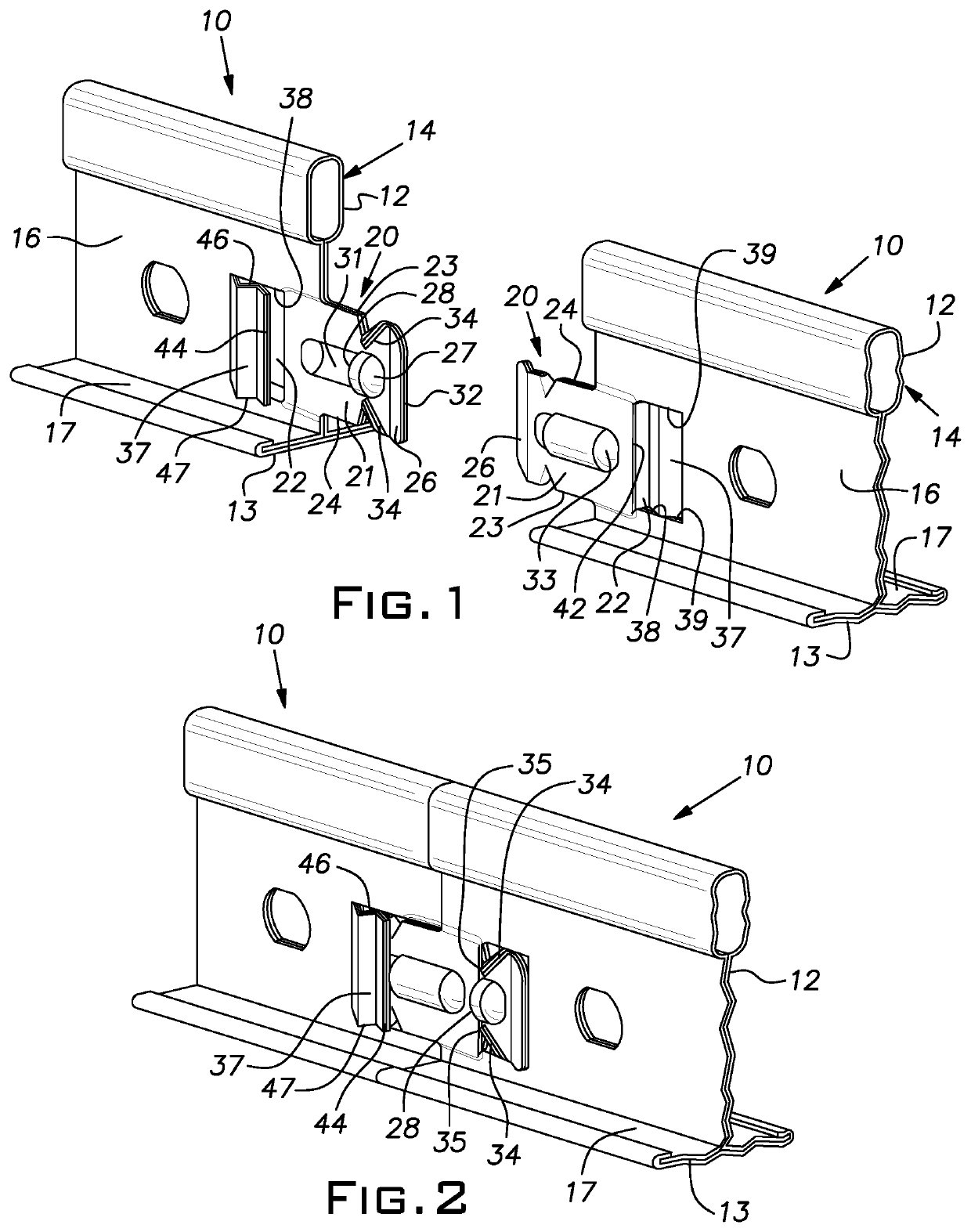

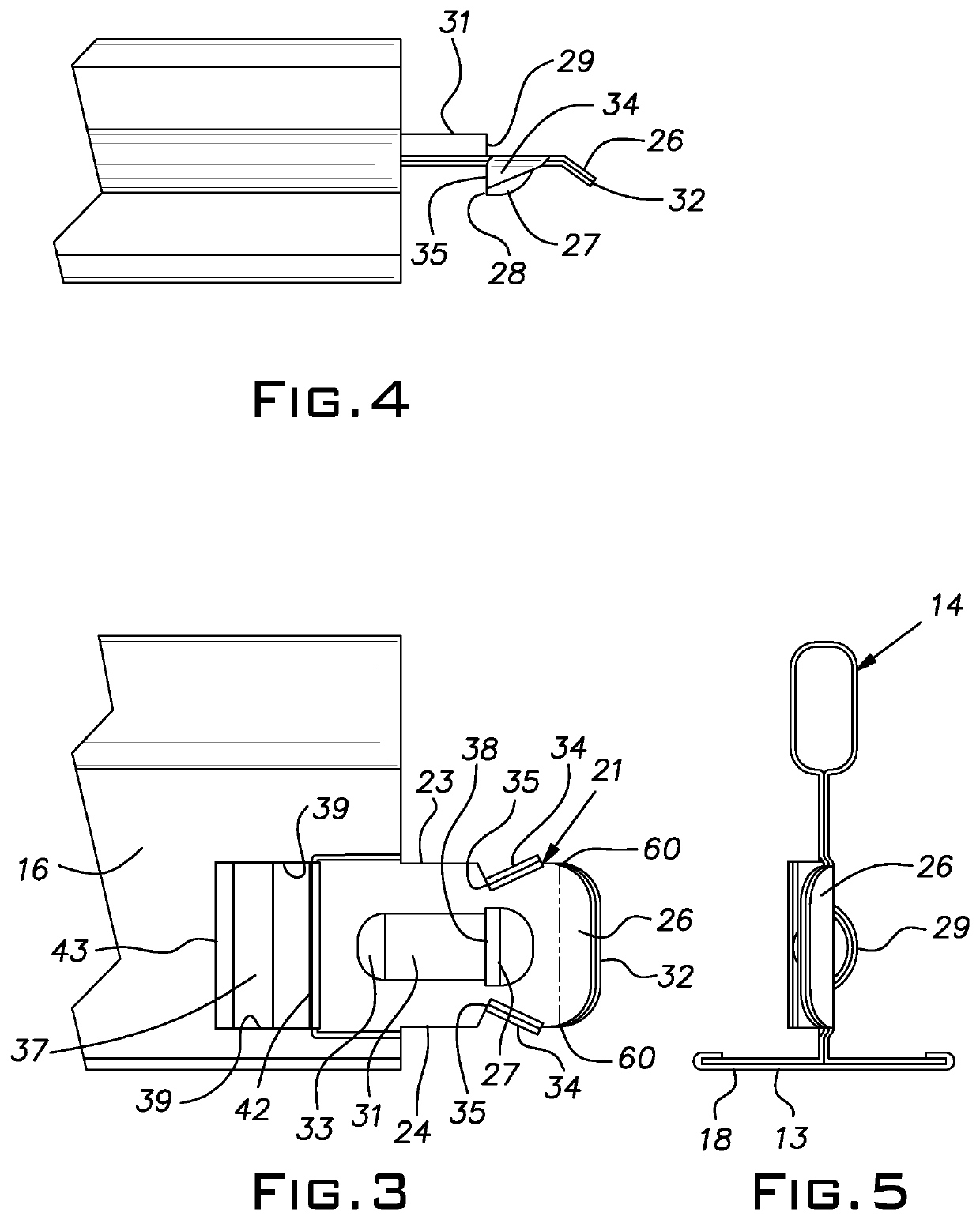

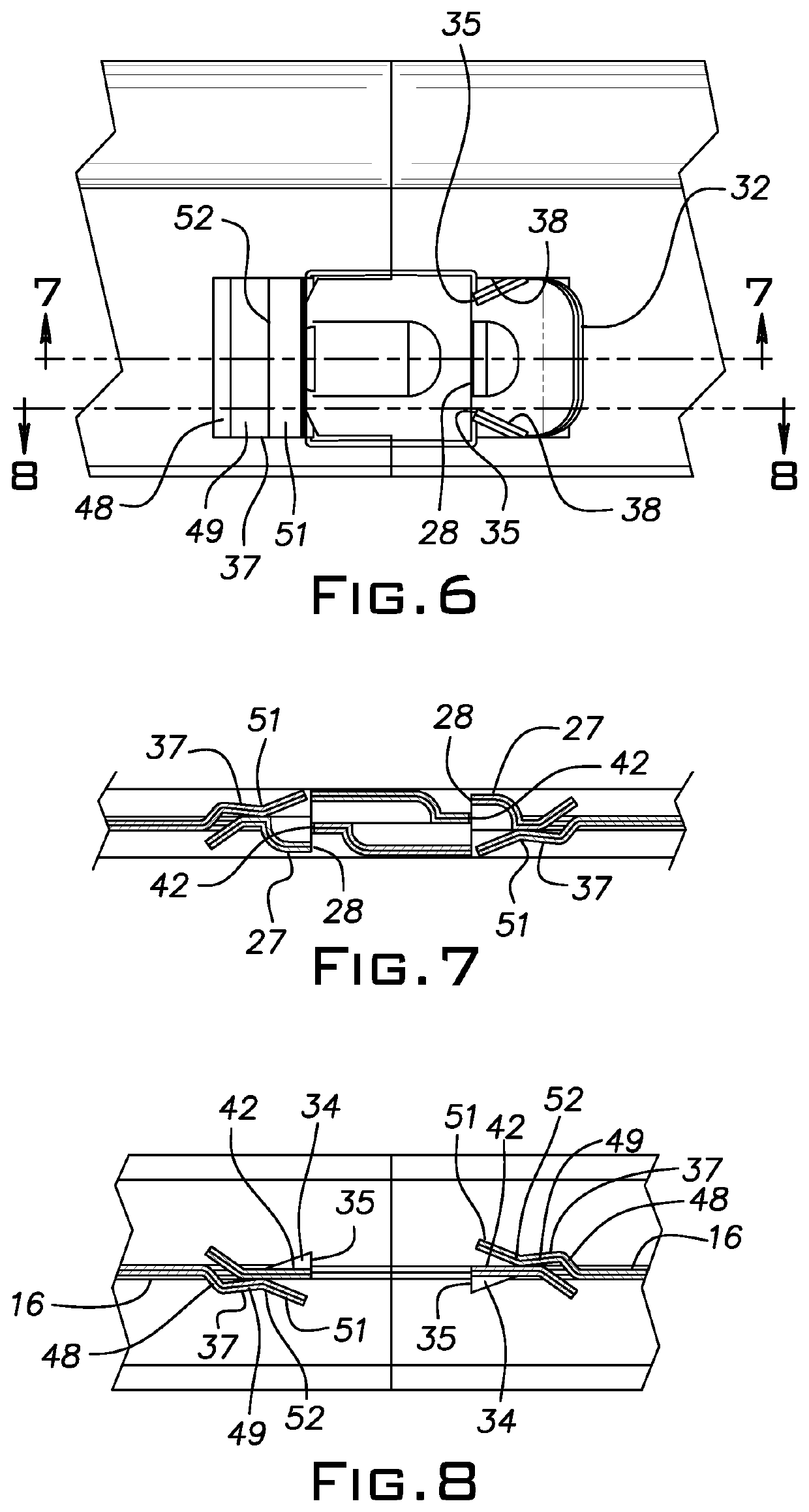

[0018]Referring now to the drawings, there is shown an end portion of a main runner or tee 10 of a general type commonly used for suspended ceiling grid systems as known in the art. Typically, such main runners or tees 10 are combined with cross runners or tees (not shown) to create a suspended grid work. In the illustrated example, the main tee 10 is made of two formed sheet metal strips 12, 13 typically of steel, although other material such as aluminum can be used. One of the strips 12 forms an upper hollow bulb 14, a double wall web 16, and oppositely extending flanges 17 all integral with one another. The strip 12 can have, for example, a thickness of 0.012″ to 0.027″ depending on the application. The other strip 13 lies under the flanges 17 and is wrapped around the distal edges of the flanges 17 to lock the strip 12 in its tee shape, conceal the seam between the flanges 17 and provide a smooth appearance for a lower face 18 of the tee 10; the lower face 18 of the strip 13 typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com