Flange screw closure and bottle having internal threads

a technology of internal threads and screw closures, which is applied in the directions of closures using stoppers, transportation and packaging, liquid handling, etc., can solve the problems of damage to wine, unsuitable for sale or consumption, and unusable for consumption, and cost the industry and consumers millions of dollars a year in unsaleable and inconsumable goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

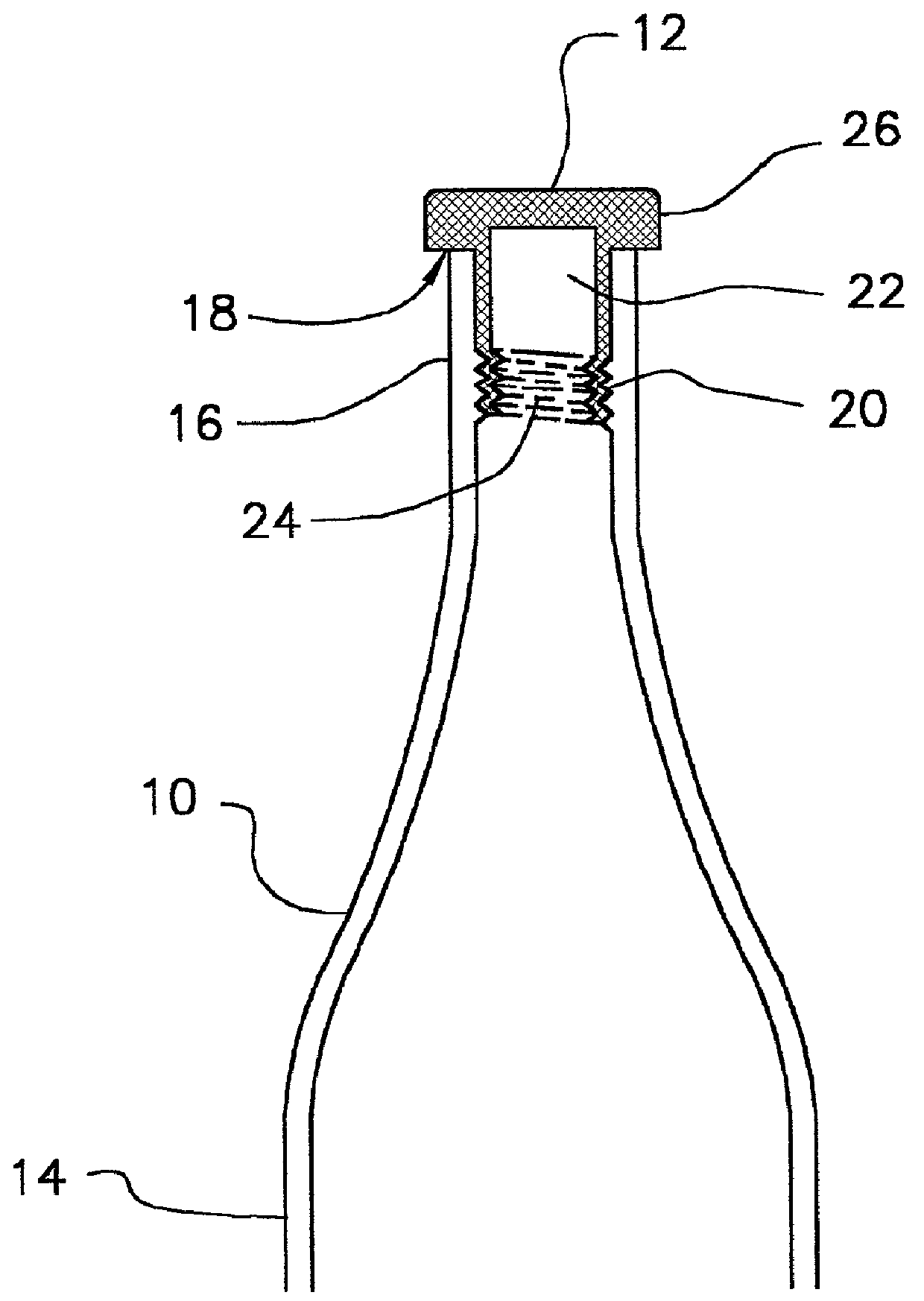

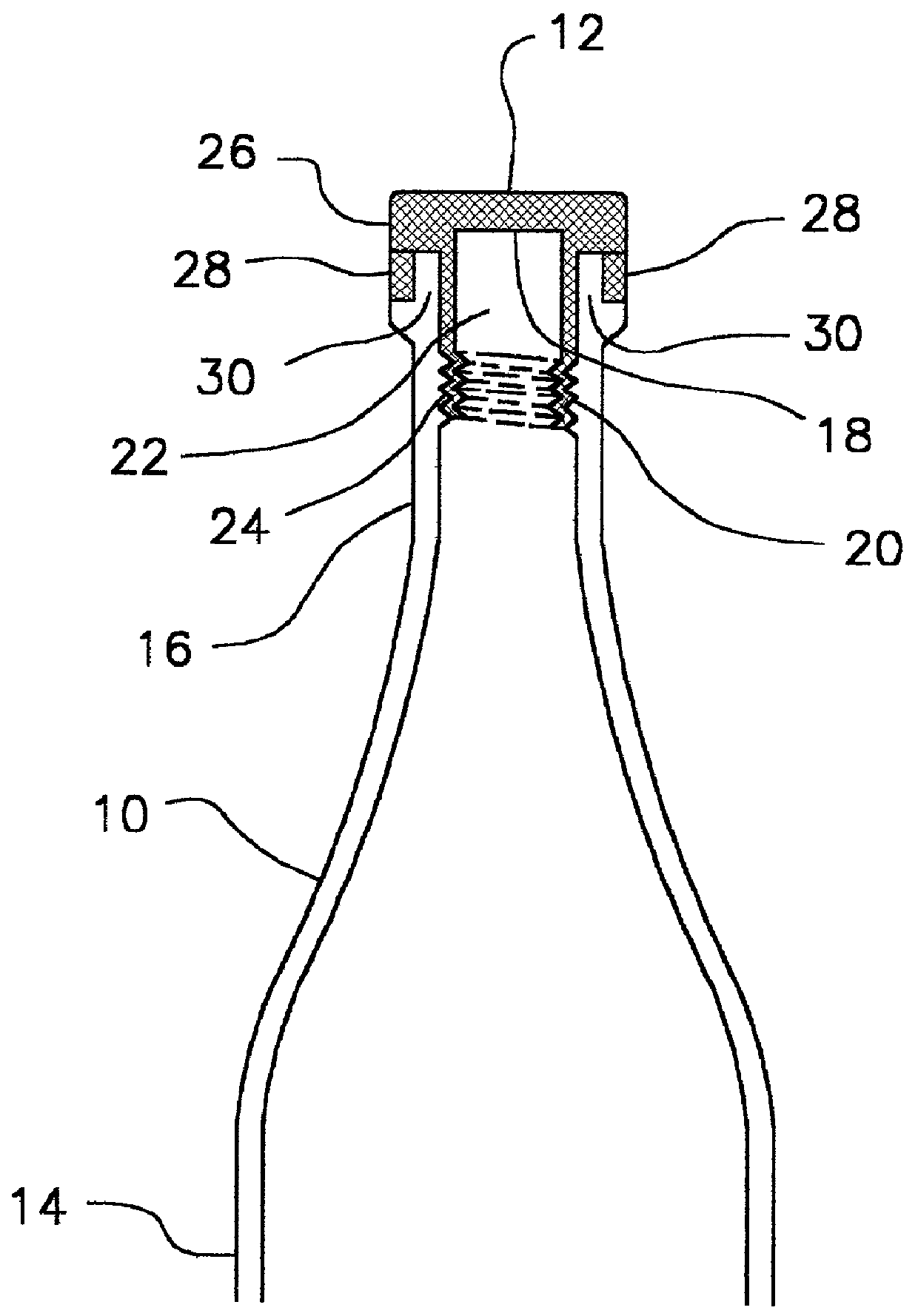

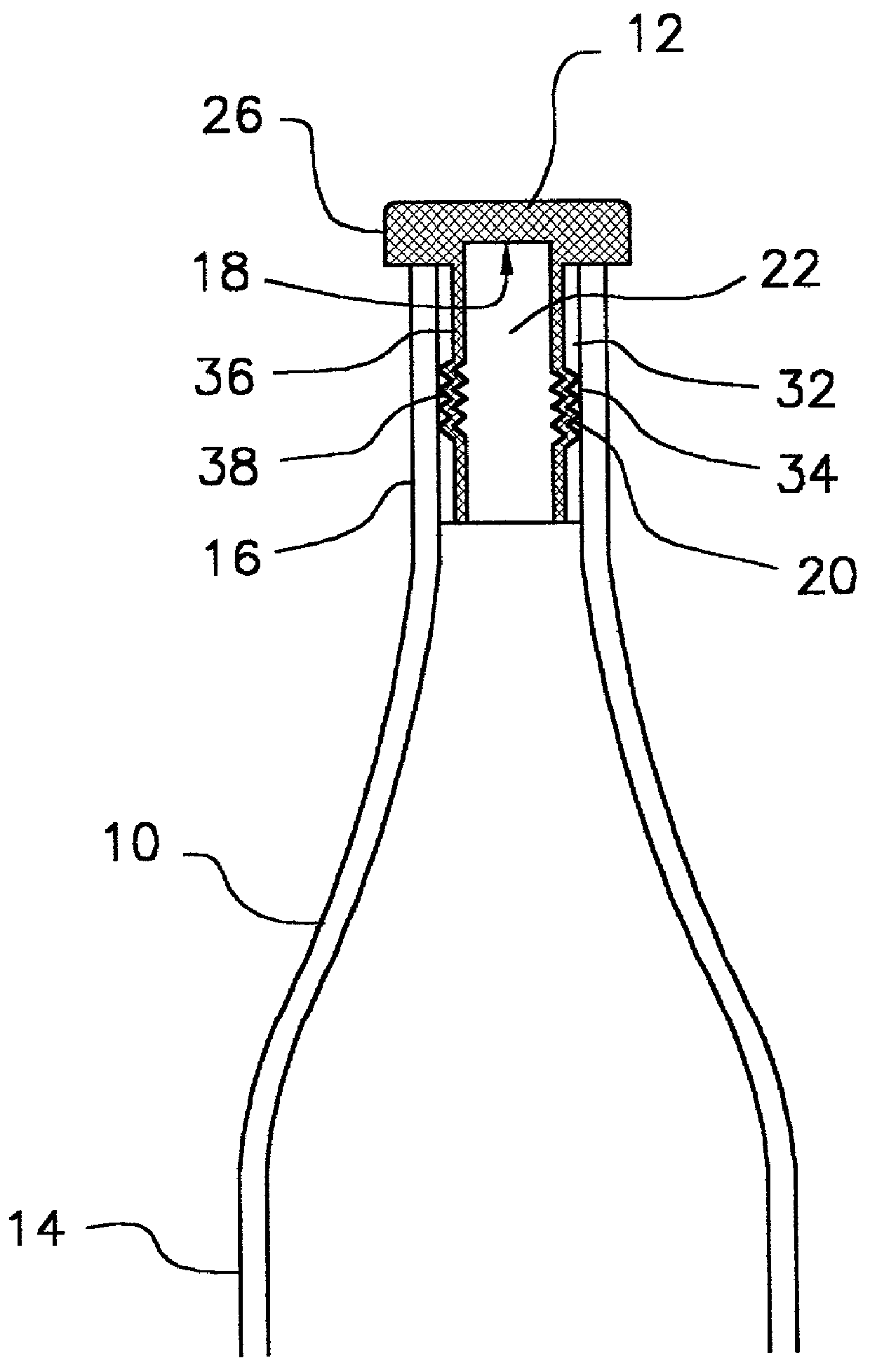

[0024] With initial reference to FIG. 1, a bottle 10 with a complementary screw closure 12 secured thereto is shown according to one embodiment of the present invention. Bottle 10 is preferably formed from cast glass using a mold, and includes a body portion 14 and a neck portion 16 which terminates in opening 18.

[0025] Bottle 10 is provided with internal spiral threads 20 disposed peripherally within neck portion 16. Internal threads 20, which commonly comprise alternating ribs and grooves for receiving complementary threads of some other member or part, are advantageously positioned low within neck portion 16 downward and away from opening 18, and spaced approximately in the range of 1 to 13 / 4 inches from opening 18. It is understood, however, that internal threads 20 may also be disposed at greater or lesser distances from opening 18. The positioning of internal threads 20 away from opening 18 affords a smooth, uninterrupted flow of wine from the bottle. Additionally, the low pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com