Wire puller

a wire puller and wire technology, applied in the field of wire pullers, can solve the problems of insufficient use, insufficient weight, and the need to substitute machine force for human force in pulling wires without significant bulk, and achieve the effect of minimizing the weight and cost of the apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

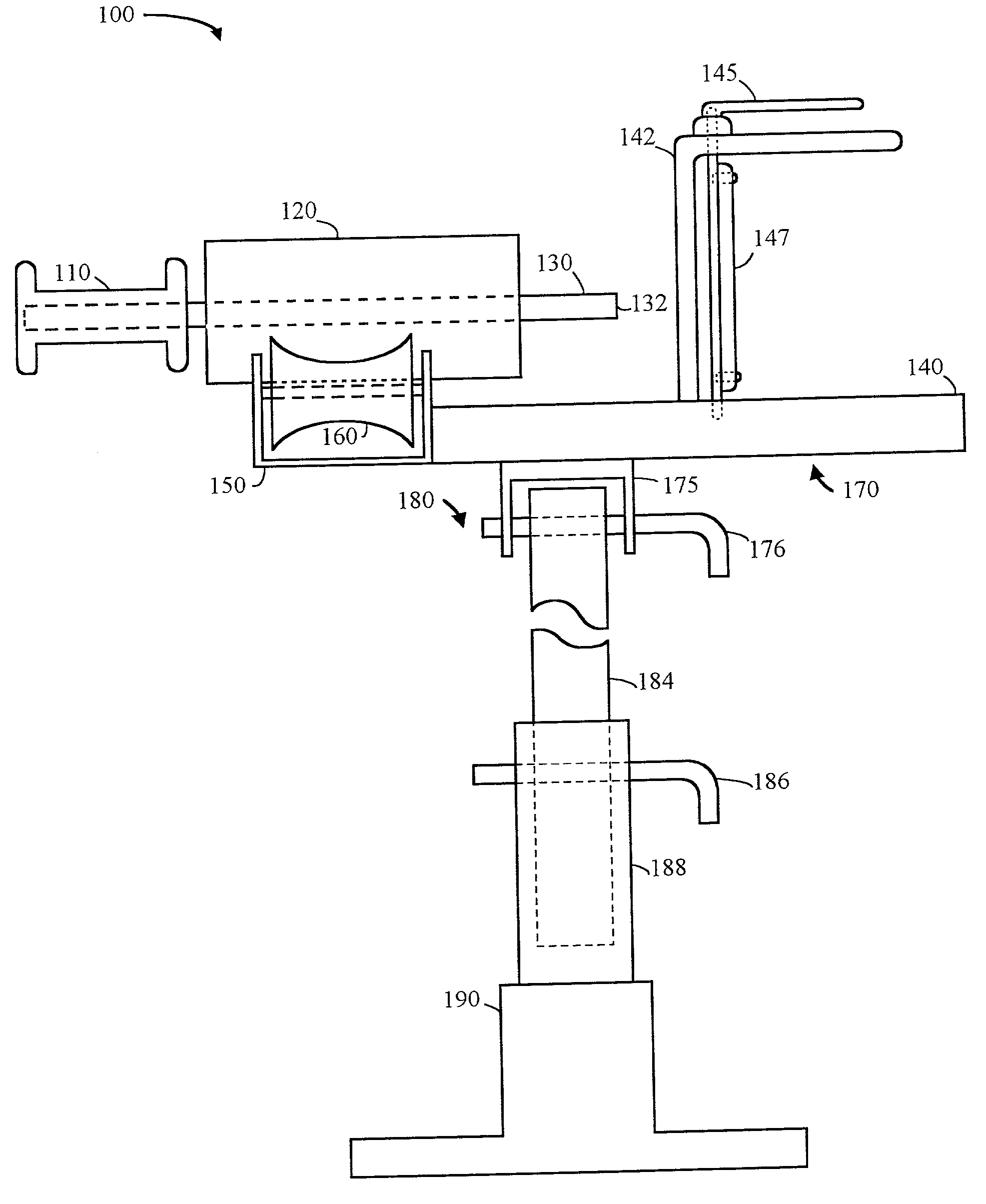

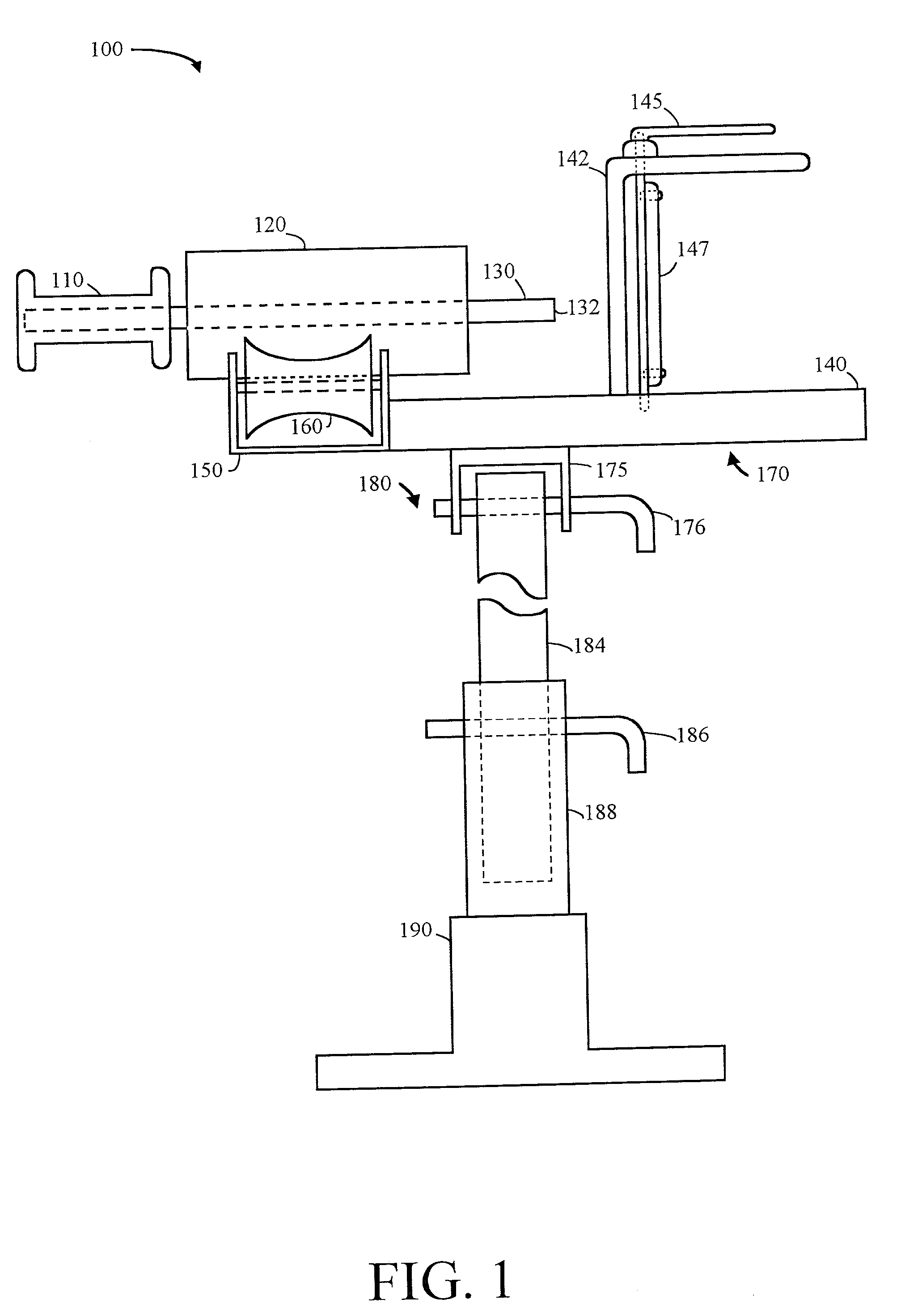

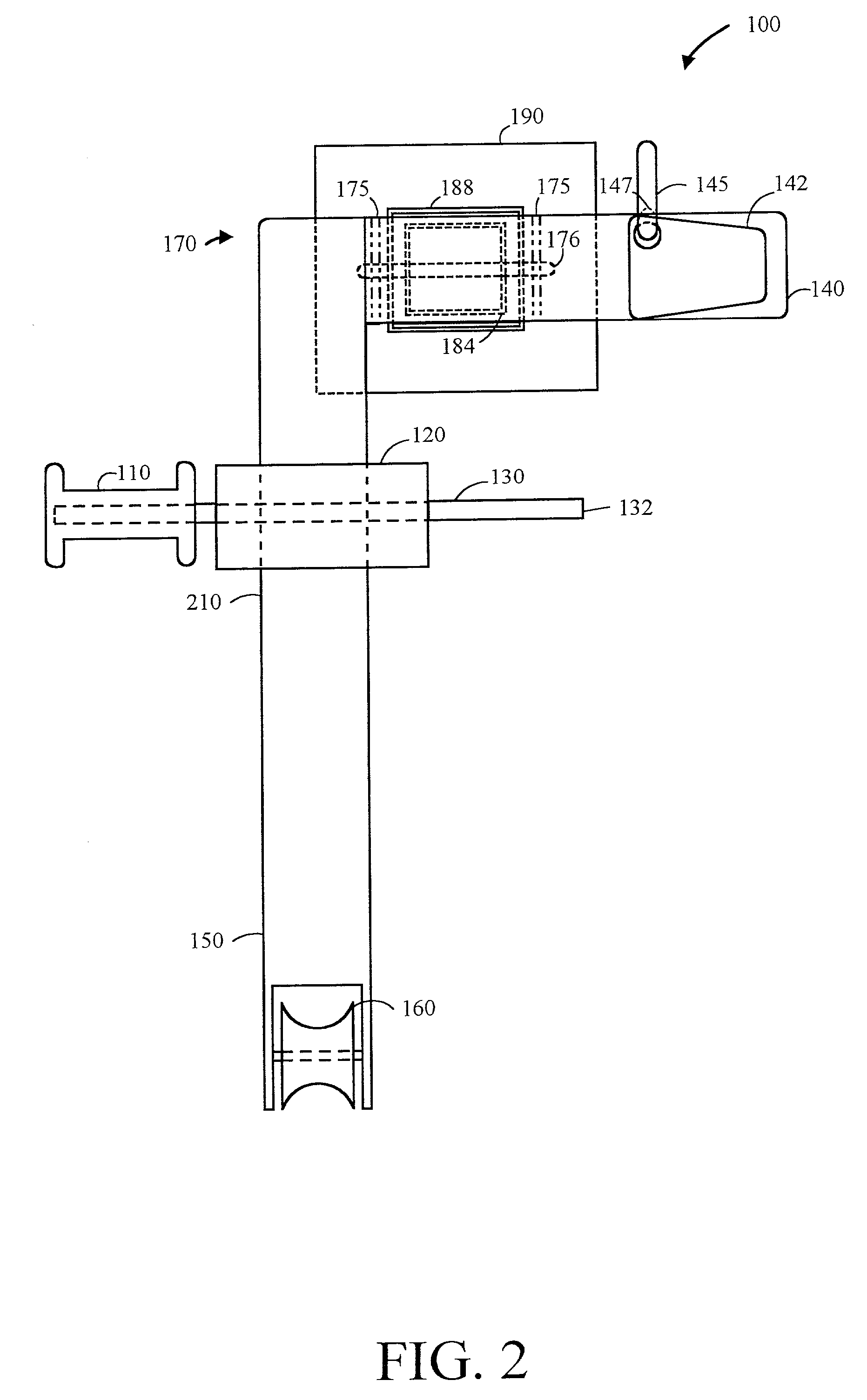

[0023] According to an embodiment of the present invention, a wire puller that utilizes the motor force of a standard right-angle power drill is disclosed. However, those skilled in the art will appreciate that any of several portable rotary power tools, such as power wrenches, can be used with the present invention. The wire puller can be operated by a single operator and disassembled to fit into a hand-held case. The hand-held case for the embodiment shown in FIGS. 1-3, measuring approximately 12 inches wide, by 21 inches long, by 7 inches high, facilitates transport of the wire puller to a location where line is to be pulled. A typical location at which line is pulled is a junction box at the end of a length of conduit. The wire puller is assembled in close proximity to the junction box.

[0024] Assembly of the wire puller shown in FIGS. 1-3 includes the steps of attaching the wire puller frame to its stand, resting the forearm frame portion of the wire puller on the junction box o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com