Opacity enhancement of tissue products with thermally expandable microspheres

a tissue product and expansion technology, applied in the field of opacity enhancement of tissue products with thermally expandable microspheres, can solve the problems of increasing the complexity of cost-effective changes, new technical challenges, and limiting factors of opacity or "see-through" of tissue products, and achieves the effect of low base weight and low base weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

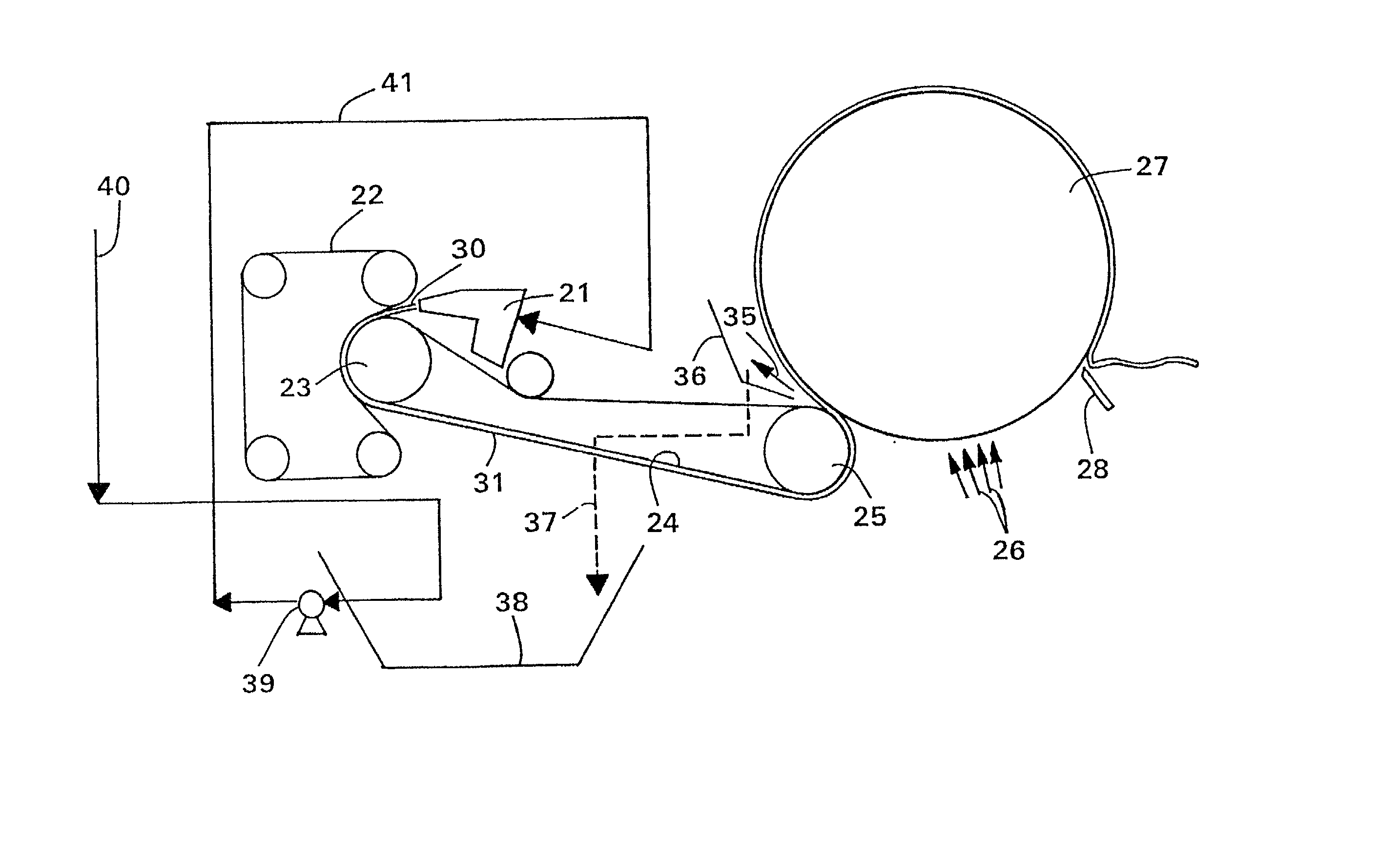

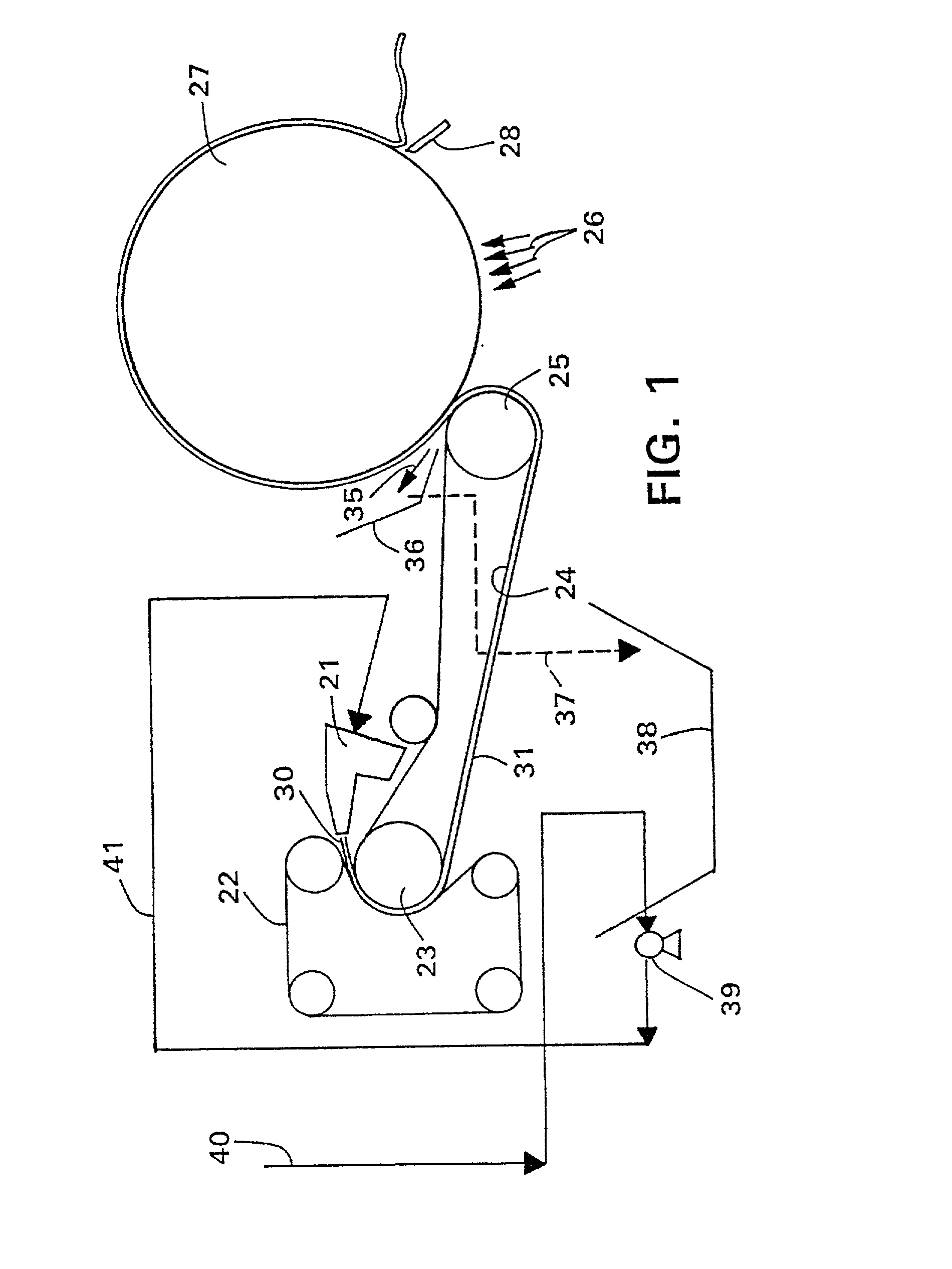

Image

Examples

examples 1-5

[0052] These five Examples demonstrate the increased opacity and decreased density of softwood kraft pulp sheets after the addition of thermally expandable microspheres. Specifically, in these Examples, EXPANCEL.RTM. 551-20 was used as the source of the thermally expandable microspheres. Also, the retention of the EXPANCEL.RTM. onto the sheets was facilitated by the addition of a cationic polyacrylamide retention aid (Nalco 7520), and the handsheets were produced according to a TAPPI Standard Procedure T205 sp-95 (with the only deviation from the standard being the use of a Valley Steam hot plate at a temperature of 213.+-.2.degree. F. instead of the typical pressing procedure).

[0053] The handsheet mold used in this standard procedure was a square wire mesh of plain weave bronze. Sufficient amounts of a thoroughly mixed pulp stock were used to produce handsheets having a basis weight of 60 gsm. As the handsheets were being formed, two different amounts of the EXPANCEL.RTM. product w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| mean diameter | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com