Methods for producing immunoglobulins containing protection proteins in plants and their use

a technology of protection protein and immunoglobulin, which is applied in the field of producing immunoglobulins containing protection protein in plants and their use, can solve the problems of unsatisfactory side effects, immunoglobulin must be functional in very harsh environments, and the mechanism of synthesis and assembly of these secretory immunoglobulins such as siga or sigm is extremely complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 7

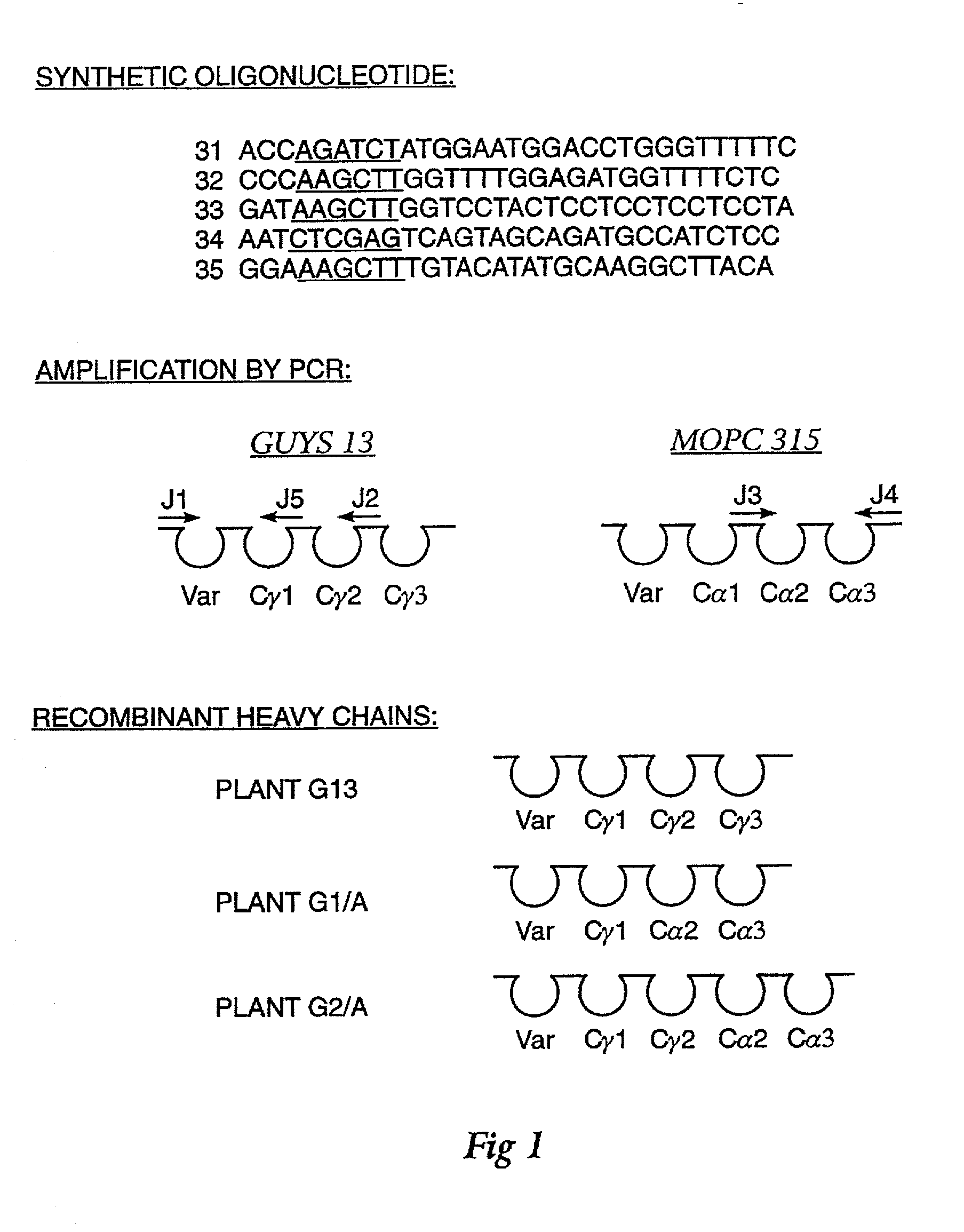

Production of Immunoglobulins Containing Protection Proteins

[0310] Four transgenic Nicotiana tabacum plants were generated to express (1) a murine monoclonal immunoglobulin kappa chain having the antigen binding site of the Guy's 13 light chain, (2) a hybrid IgA / G murine immunoglobulin heavy chain containing C.gamma. and C.alpha. chain domains and the antigen binding site of the Guy's 13 heavy chain, (3) a murine J chain and (4) protection protein comprised of amino acids 1-606 of rabbit polyimmunoglobulin receptor and did not contain amino acids 627-675 of the rabbit polyimmunoglobulin receptor. See, Example 1. Successive sexual crosses between these plants resulted in simultaneous expression of all four protein chains in the progeny plants. In some cases, back crossing was used to produce homozygous plants. The four recombinant polypeptides were assembled into a functional, high molecular weight immunoglobulin containing a protection protein of approximately 470,000 Kd. The assemb...

example 8

Production of a Useful Plant Extract Containing Immunoglobulins Having a Protection Protein

[0335] Plant pieces (either leaf, stem, flower, root, or combinations) from plants producing immunoglobulins containing a protection protein were mixed with homogenization buffer (2 milliliter buffer per gram of plant material; homogenization buffer: 150 mM NaCl, 20 mM Tris-Cl, pH 7.5), homogenized into a pulp using a Waring blender and centrifuged at 10,000.times. g to remove debris. The supernatant was then extracted with an equal volume of HPLC-grade ethyl acetate by shaking at room temperature, followed by centrifugation at 10,000.times. g. The aqueous phase was transferred to another container, remaining ethyl acetate was removed from the aqueous phase by placing the solution under vacuum. The resulting crude extract consistently contained 100 .mu.g immunoglobulin having a protection protein per ml. This method is useful for any plant containing an immunoglobulin having a protection prote...

example 9

Stability of an Immunoglobulin Containing a Protection Protein

[0338] Two sets of crude plant extracts were prepared as described above. The first extract was derived from a plant expressing an IgG1 antibody and the second extract was derived from a plant expressing an immunoglobulin containing a protection protein. Crude plant extracts of this type from plants are known to contain a variety of proteolytic enzymes. Prolonged incubation of extracts at room temperature or at 37.degree. C. therefore constitutes a proteolytic digestion.

[0339] Using ELISA the quantity of gamma-kappa complexes in the two extracts was determined as a function of time at both room temperature and 37.degree. C. In these assays, an anti-kappa chain antibody was used to coat the plate followed by incubation with the plant extract at 37.degree. C. for 1 hour. An anti-gamma chain antibody conjugated to HRPO was used for detection of immunoglobulin derived from the plant. The quantity of immunoglobulin having a pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speeds | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com