Retractable roller mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

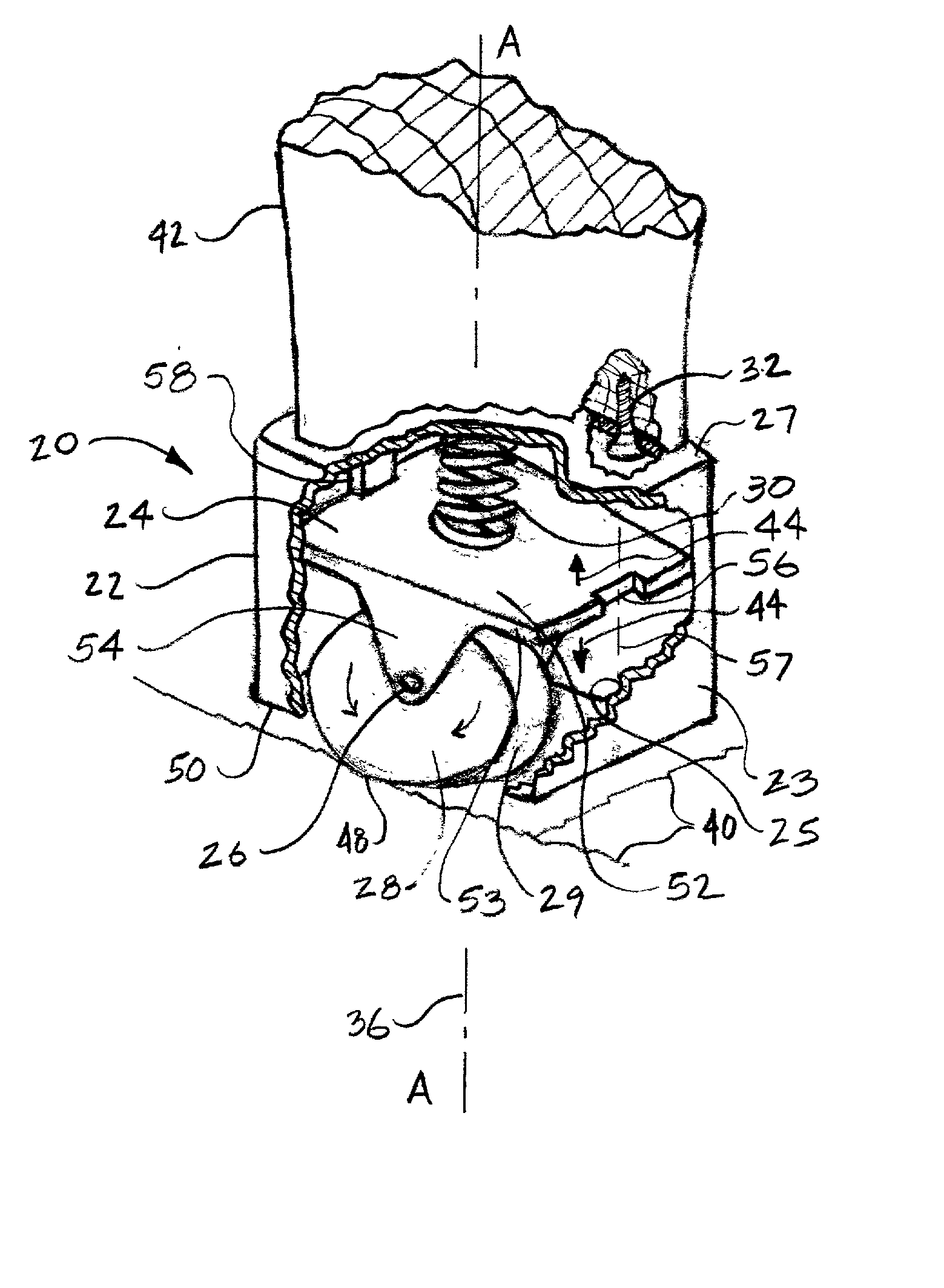

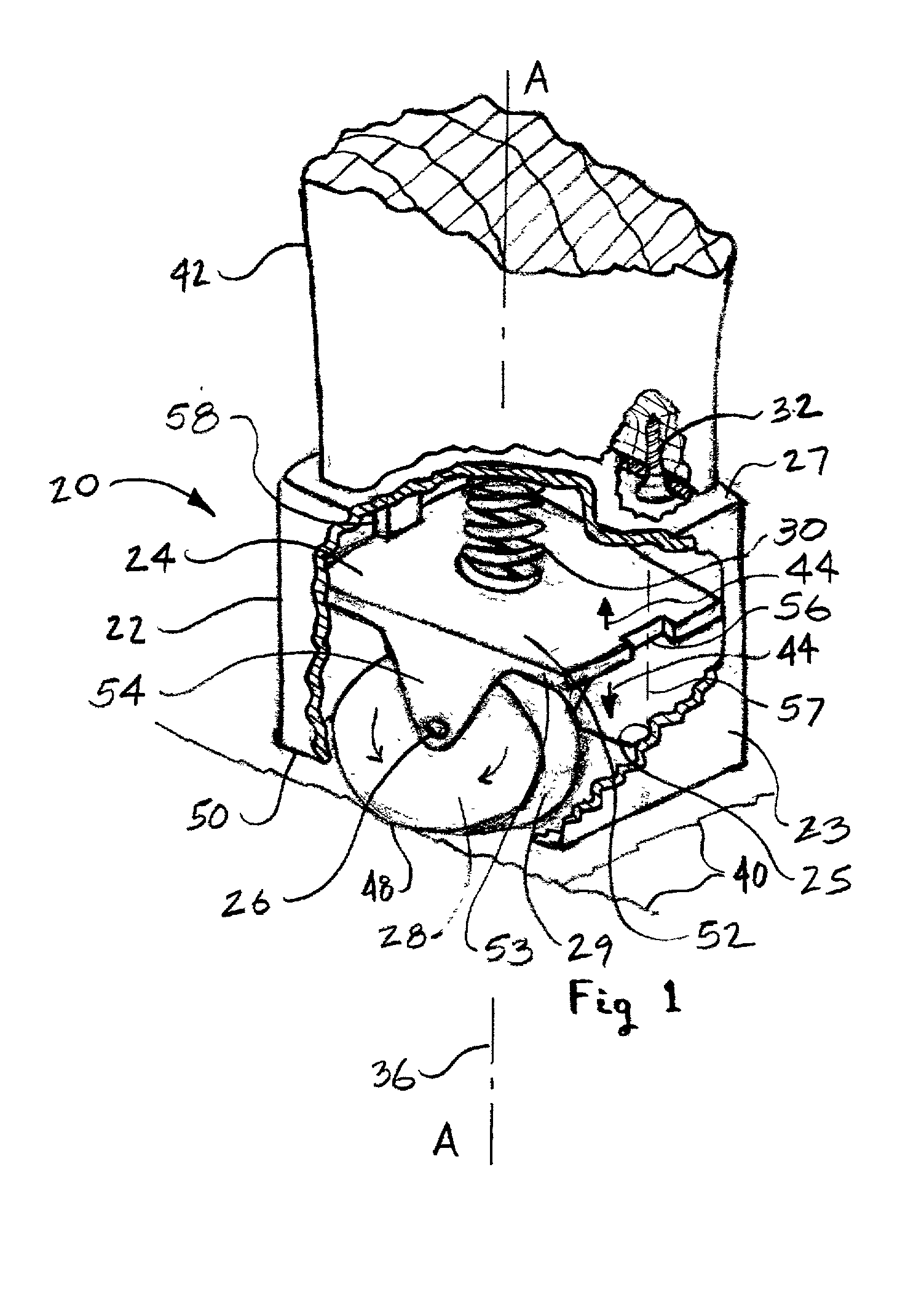

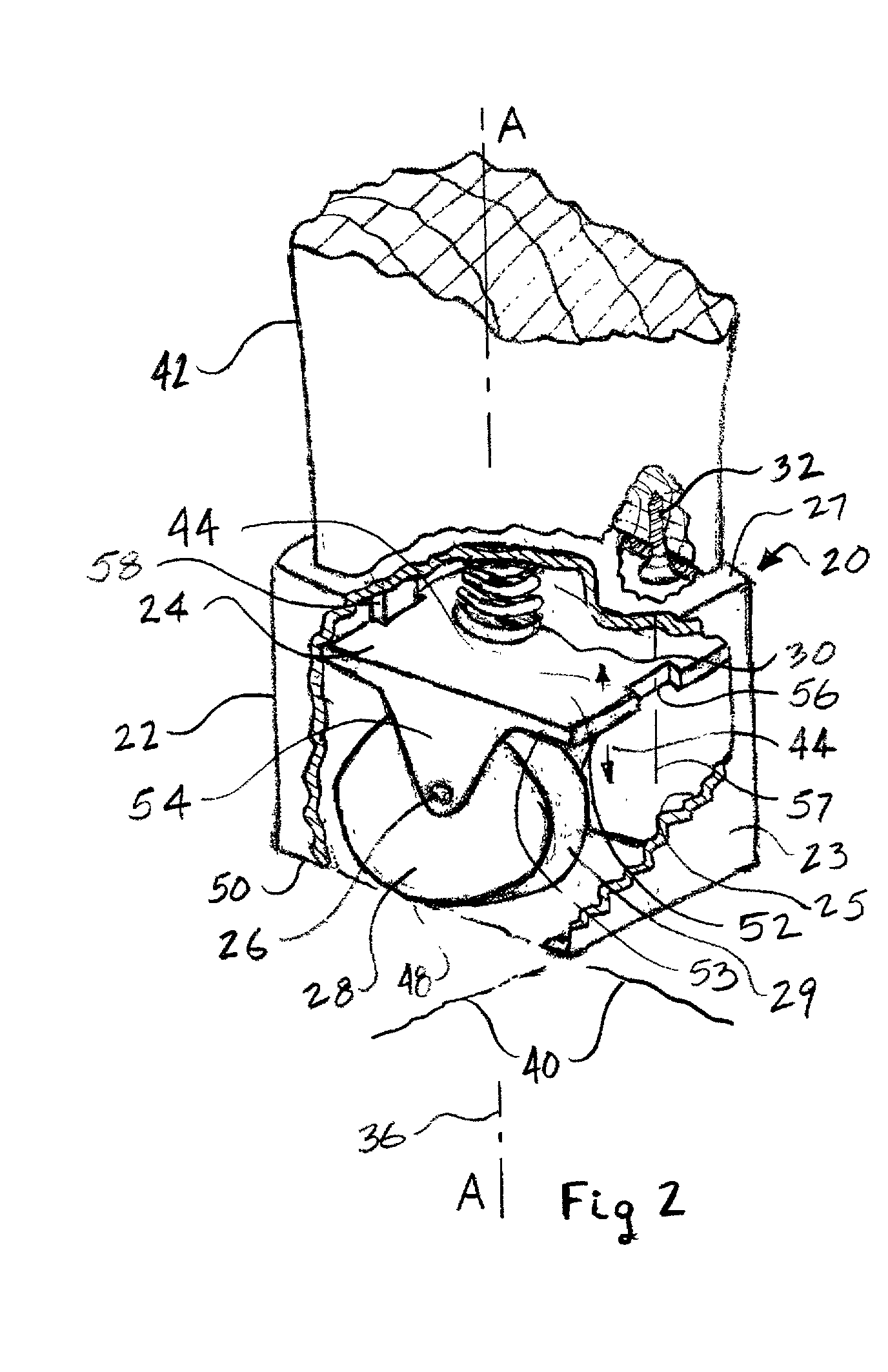

[0063] Referring to FIGS. 1 and 2 for the preferred embodiment, a method is given for using the retractable roller mechanism 20 for statically supporting an item 42 upon the support surface 40 with the retractable roller mechanism 20 in an inoperative state and supporting the item 42 to roll along the support surface by use of the retractable roller mechanism 20 in an operative state. Item 42 will typically be adpated toward having two operative states being desired by the individual in using the item 42, necessitating that the item 42 have its weight increased in a static position. The first state or operative state is where it is desired to have the item 42 be moveable along a support surface 40 to a desired position, where an an individual provides the motive force to move the item across the support surface 40, once the desired position is obtained then the individual will quit providing a motive force to item 42, allowing item 42 to be statically positioned at its desired locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com