Vibratory separator screens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

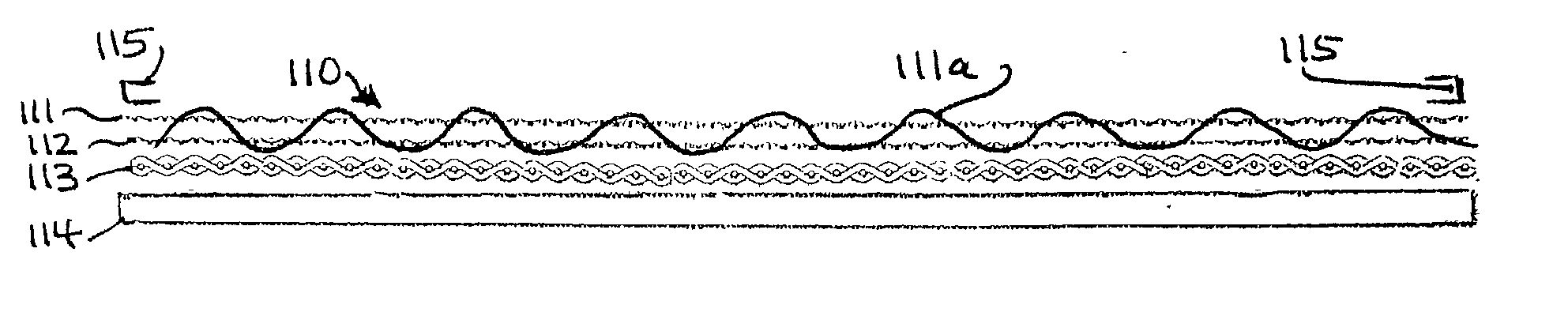

[0031] FIG. 1A shows a glued-together screen combination 10 with lower coarse mesh 11 and upper fine mesh or meshes 12. Following the gluing operation and curing of the glue 131, portions of the upper mesh or meshes are rippled, wavy, or non-flat (as shown). Following mounting (by epoxy powder or by hot melt glue) of such a screen combination 10 to a tubular frame and then subjecting the resulting screen assembly to vibration on a vibratory shaker while fluid at a temperature above ambient temperature (e.g. at least five to twenty degrees hotter than ambient and including, but not limited to drilling fluids from a wellbore up to 160.degree. F. or higher) is fed to the screen assembly, the non-flat portions of the screening material tighten and flatten, as shown in FIG. 1B.

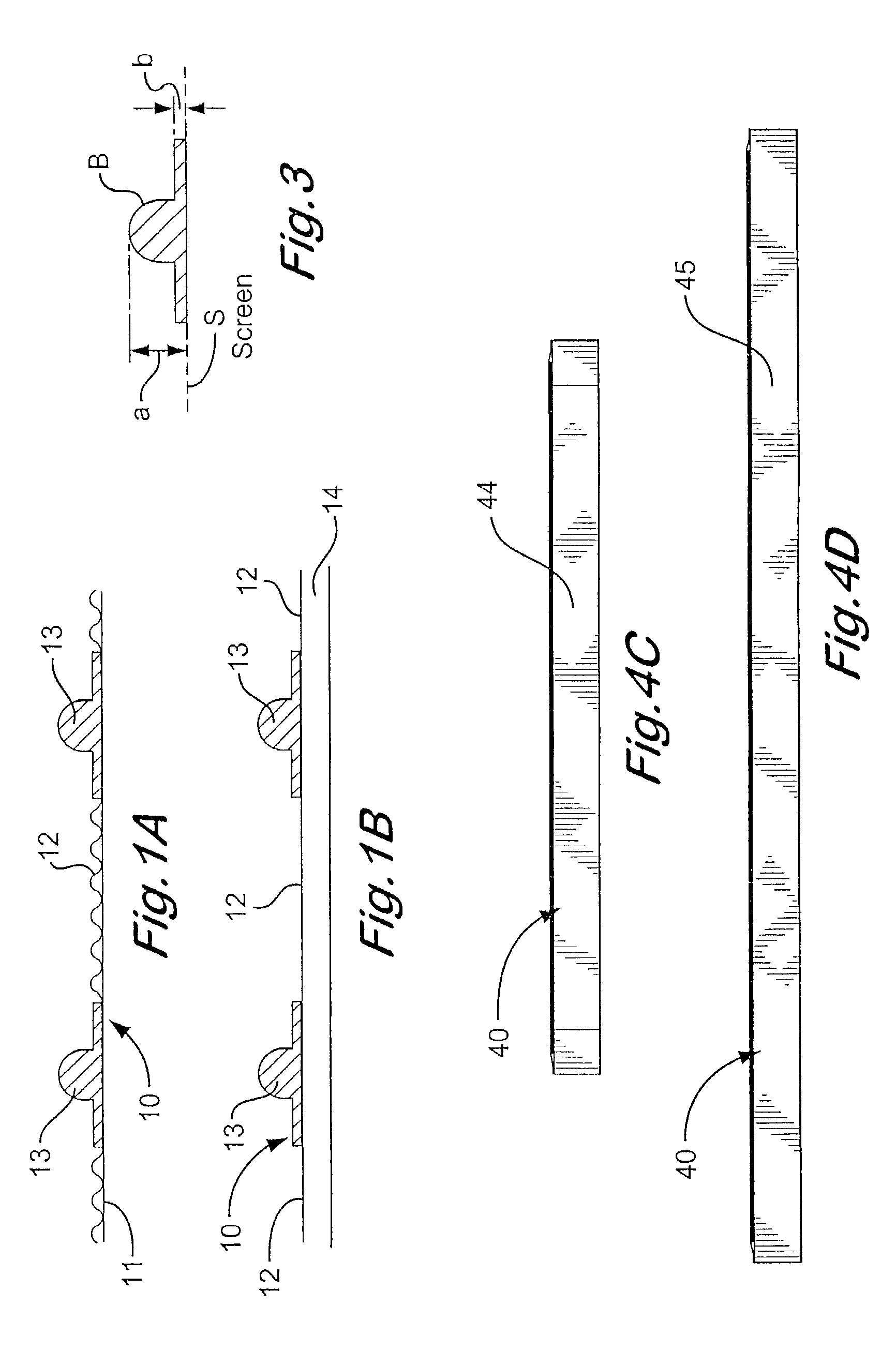

[0032] FIG. 3 shows a cross-section or one glue bead's B profile applied to a screen S. The distance "a" is, in this embodiment, about one-sixteenth of an inch but may be any desired height as applied. Preferably t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Mesh size | aaaaa | aaaaa |

| Mesh size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com