Apparatus and method especially for holding a separate piece to be attached to a unit load

a technology of a separate piece and a unit load, which is applied in the field of apparatus and methods for holding a separate piece to be attached to a unit load, can solve the problems of mechanical attachment, difficult to ensure the safety of the protector, and the edge of the material can become dirty throughout the entire length of the web, so as to achieve easy and rapid construction, easy and rapid process, and easy to test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

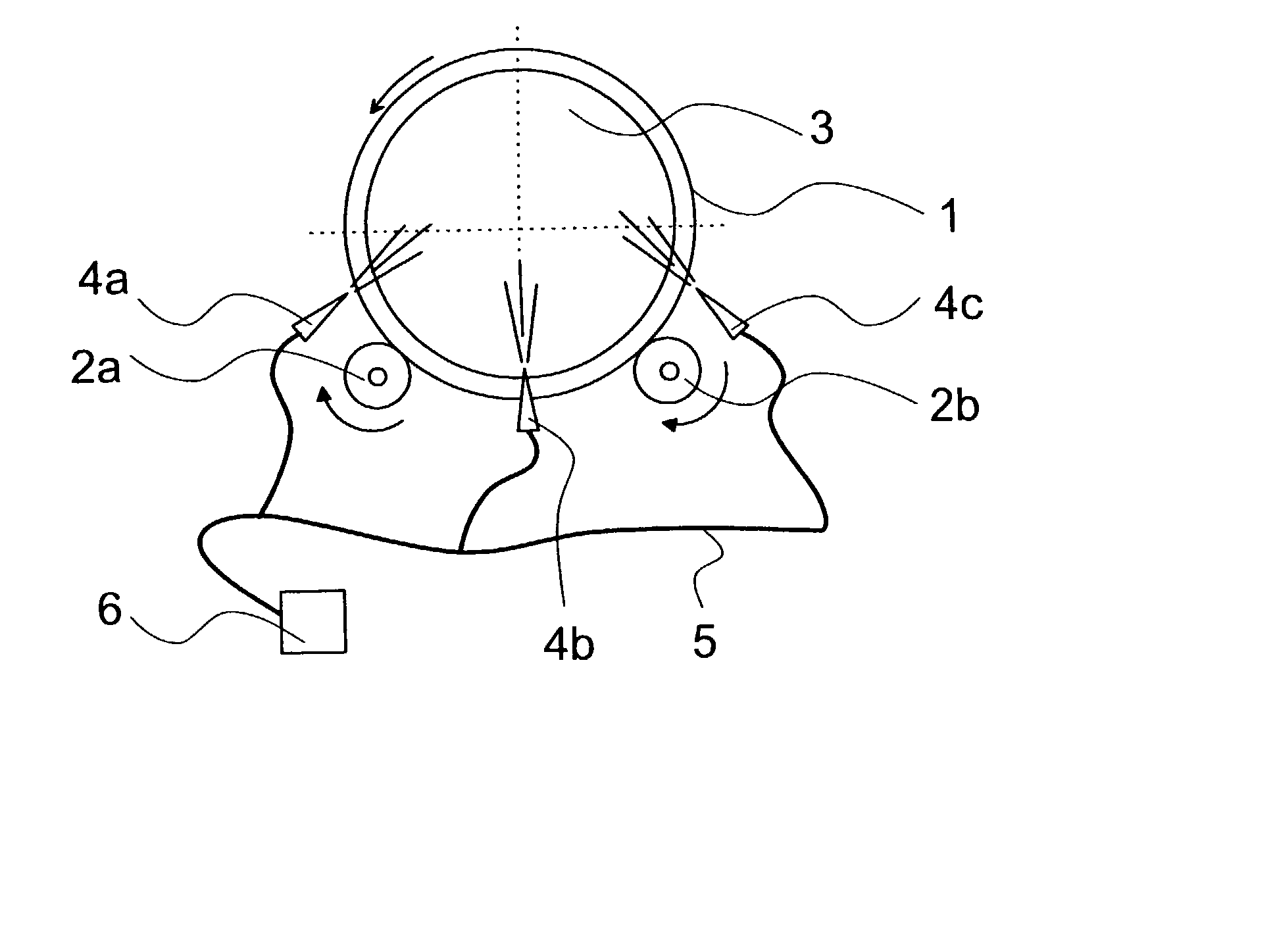

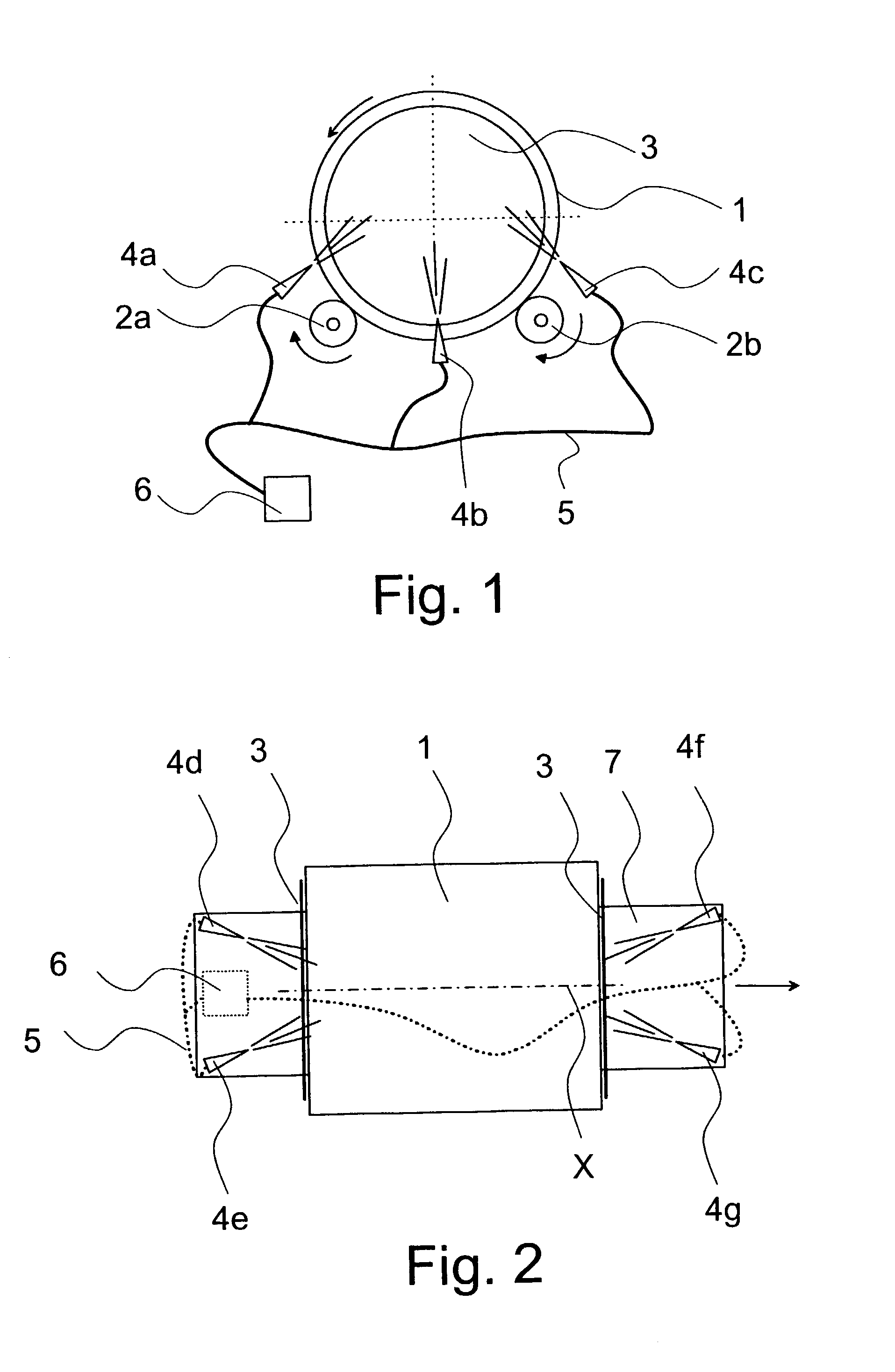

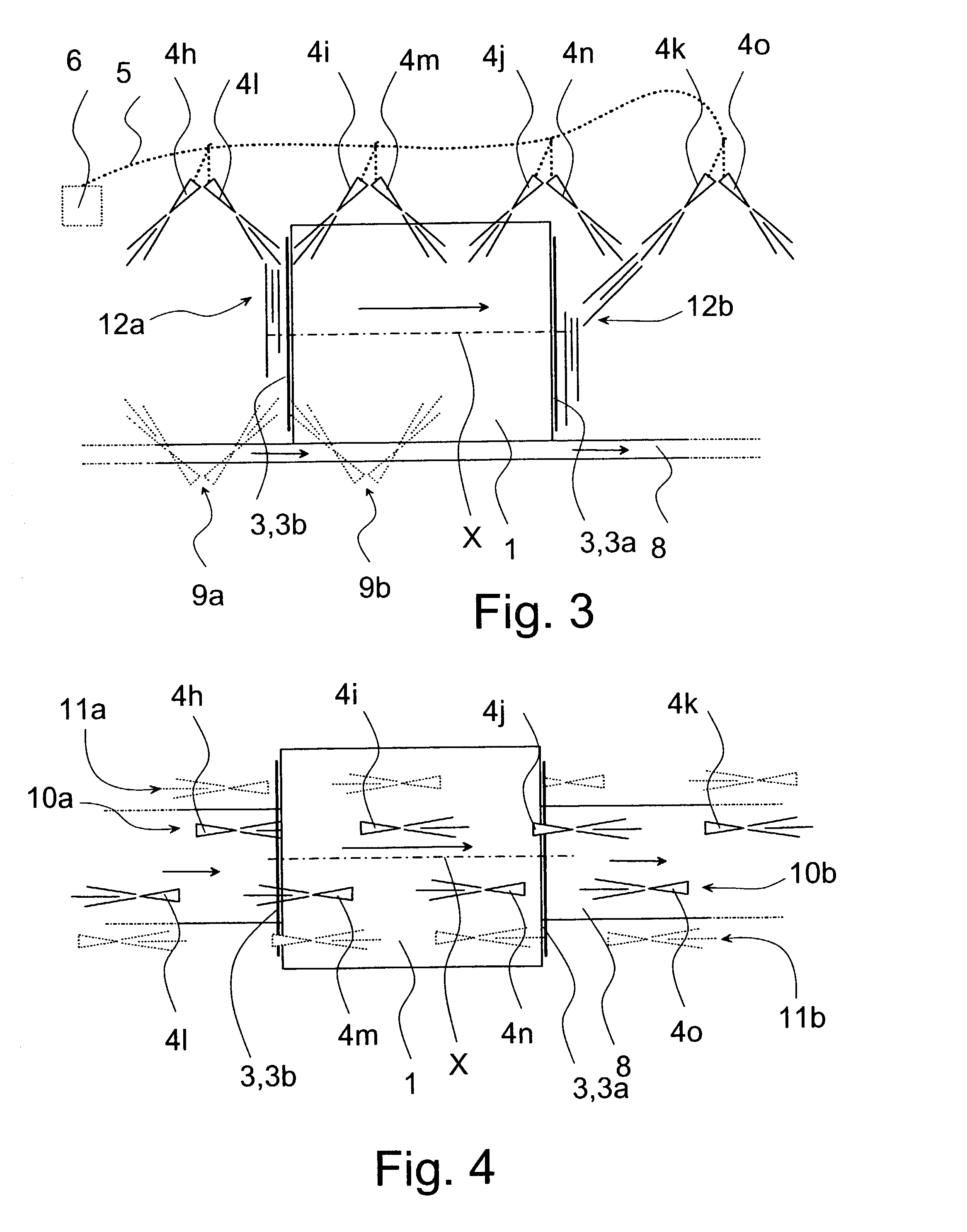

[0019] FIG. 1 shows a reduced principle view of the invention, in which only the essential aspects of the different structures have been shown. The technique used for the transfer and rotation of the roll is known as such, and thus the operation of the same will not be discussed in more detail in this context. A paper roll 1 is used as an example. The roll 1 is rotated around its longitudinal axis by means of two rotating rollers 2a, 2b. The rollers 2a, 2b are rotated by motor means around axes of rotation that are parallel to the longitudinal axis of the roll 1. The rotating apparatus is known as such and comprises for example the necessary frame structure. A continuous belt can also be passed via the rollers 2a, 2b that are typically longer than the roll 1, wherein the roll 1 rests on the support of the belt, and smaller surface pressures are attained.

[0020] Against the end of the roll 1 an end protector 3 has been placed for example manually or automatically by means of an appara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com