Building System for Constructing Walls

a building system and vertical wall technology, applied in the direction of building components, public buildings, building insulations, etc., can solve the problems of large sealing problems, difficult and expensive construction, and long log operations, etc., and achieve the effect of easy handling and easy and inexpensive production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

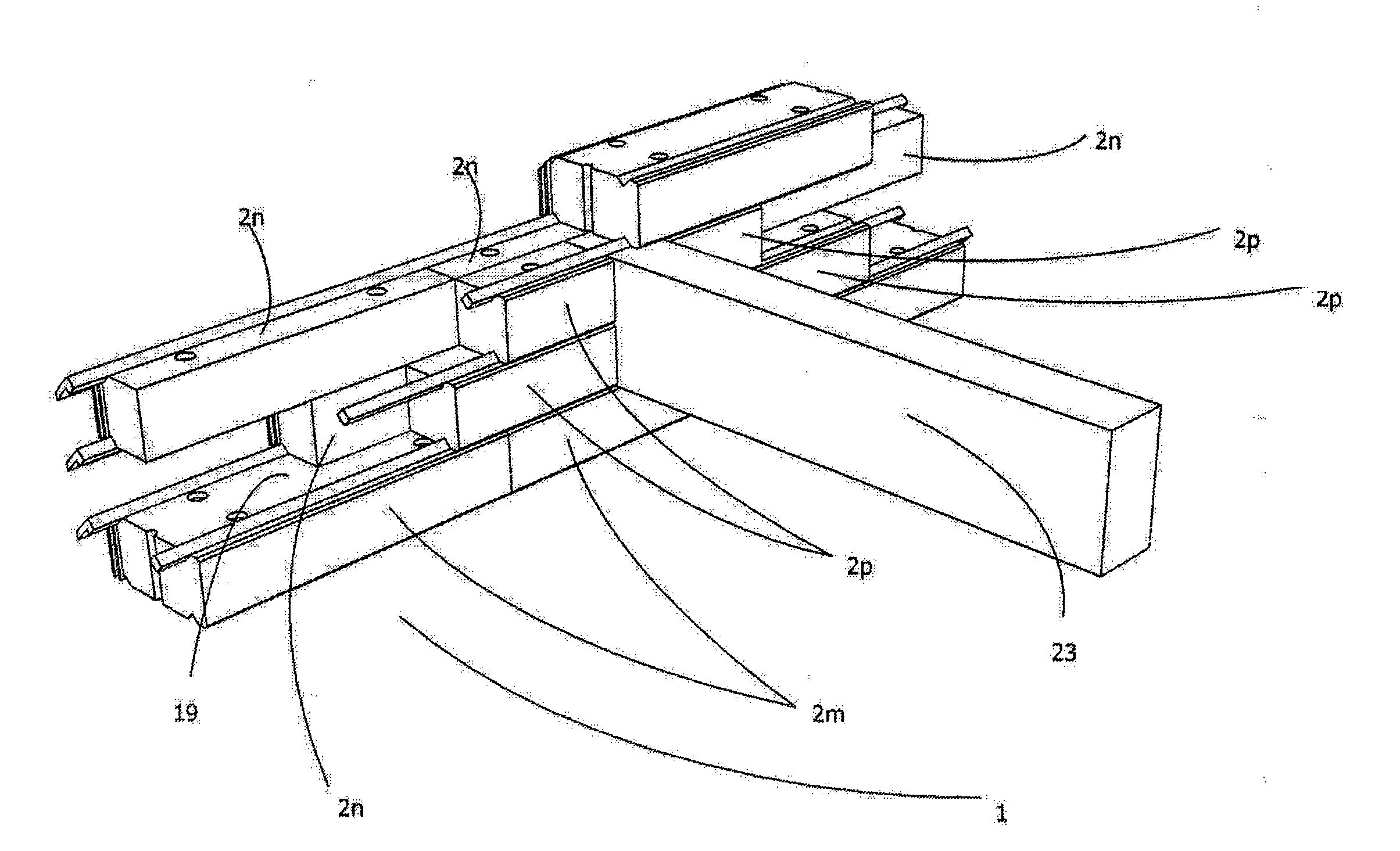

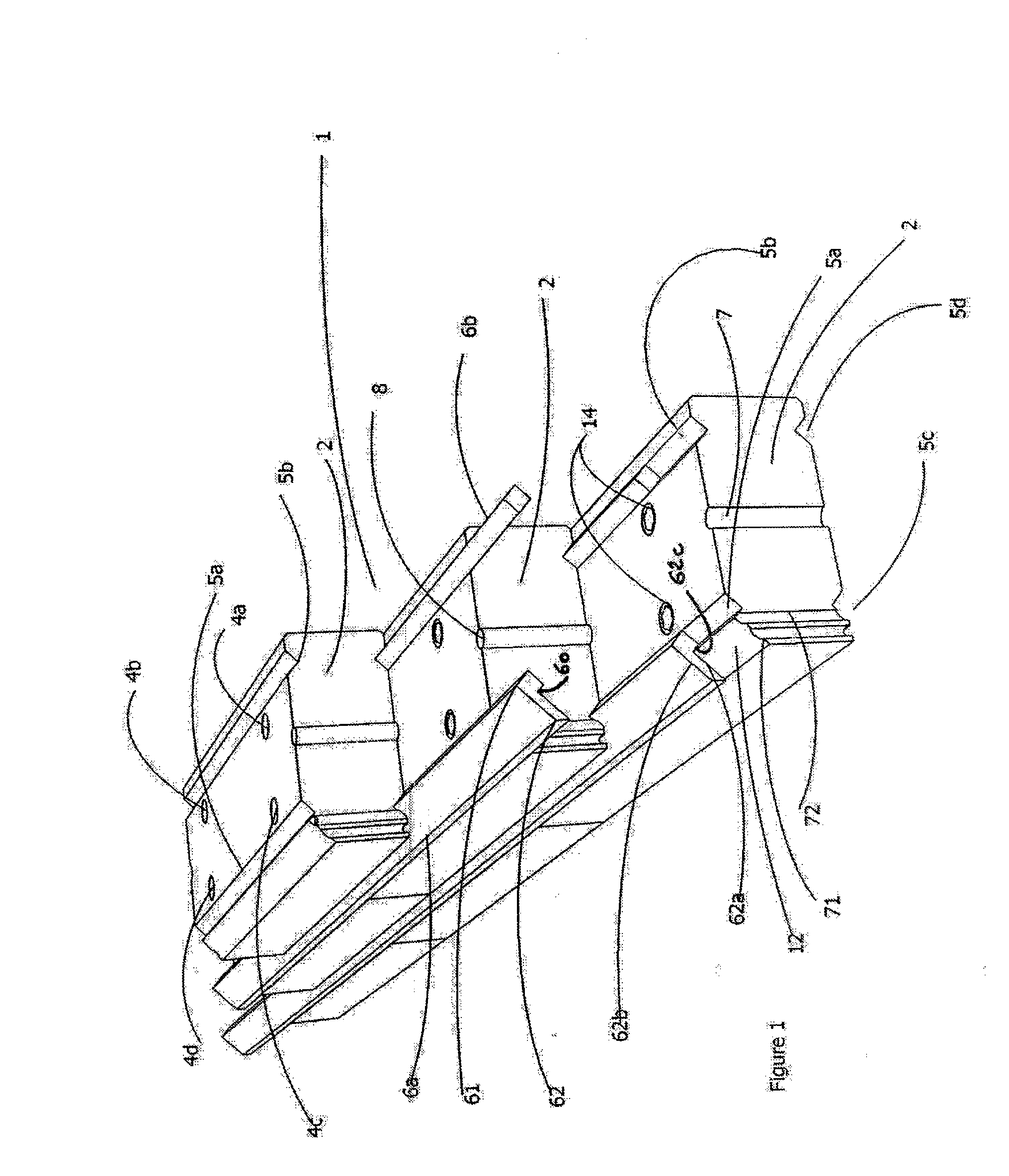

[0081]FIG. 1 is a perspective view of an example of a wall under construction, made using the building system according to the invention.

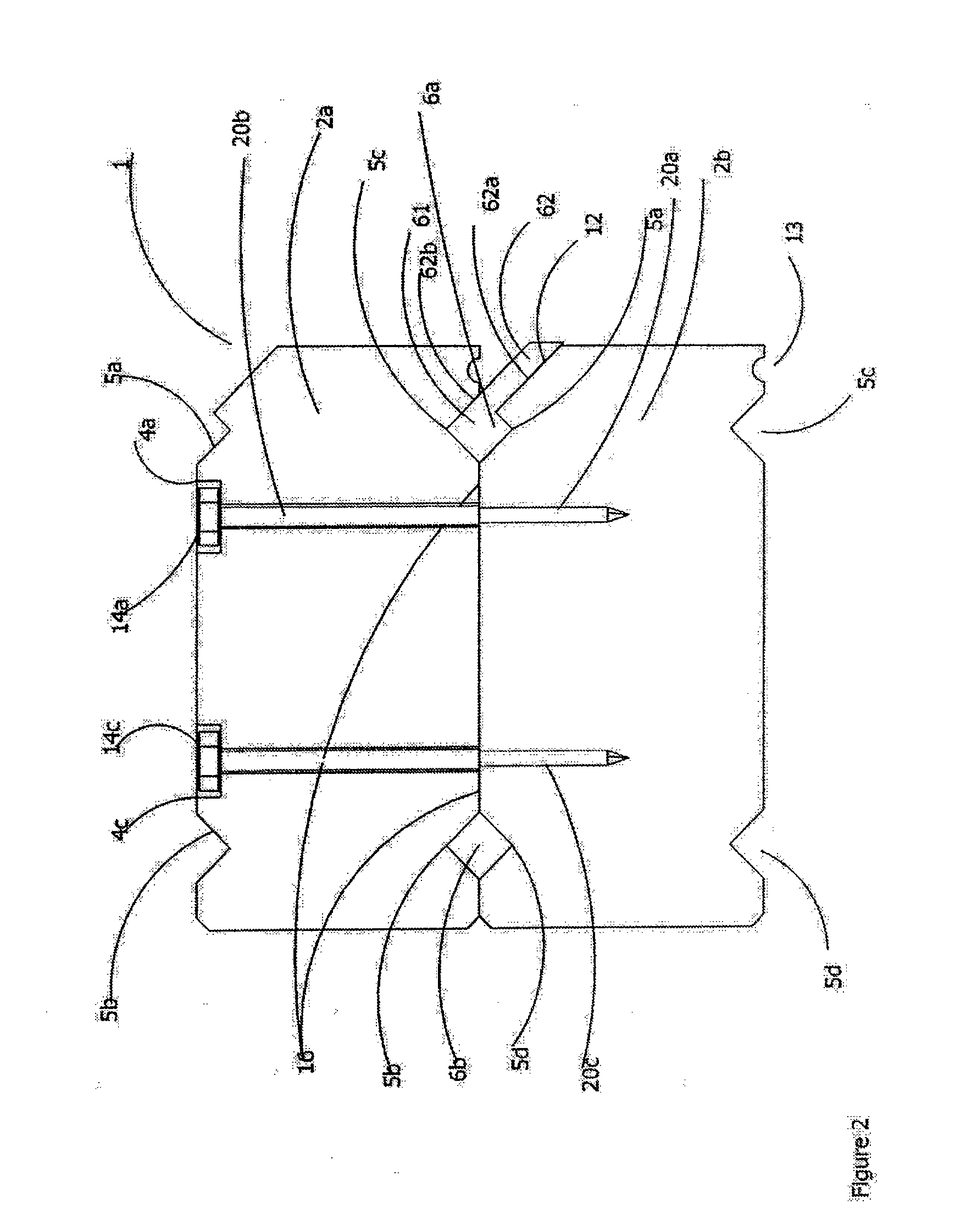

[0082]The wall 1 comprises wooden building blocks 2 of rectangular parallelepipedal shape, which are placed beside one another and on top of one another in a staggered fashion. The blocks are preferably made of solid wood. However, they may also be made of fiber components. The upper horizontal longitudinal face of the blocks 2 includes two grooves 5a, 5b parallel to the longest side of the face and running along the entire length of this face. Likewise, the lower horizontal longitudinal face of the blocks 2 includes two grooves 5c, 5d parallel to the longest side of the face and running along the entire length of this face. Preferably, the two grooves 5a, 5b of the upper face are arranged symmetrically with the two grooves 5c, 5d of the lower face.

[0083]The edge near the intersection between the upper face and the outer face of the blocks 2 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com