Thermal deck

a deck and thermal insulation technology, applied in the field of house insulation, can solve the problems of poor heat transfer characteristics, poor conductors, and less than desirable insulation properties of roof systems, and achieve the effect of improving insulation and heat transfer characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

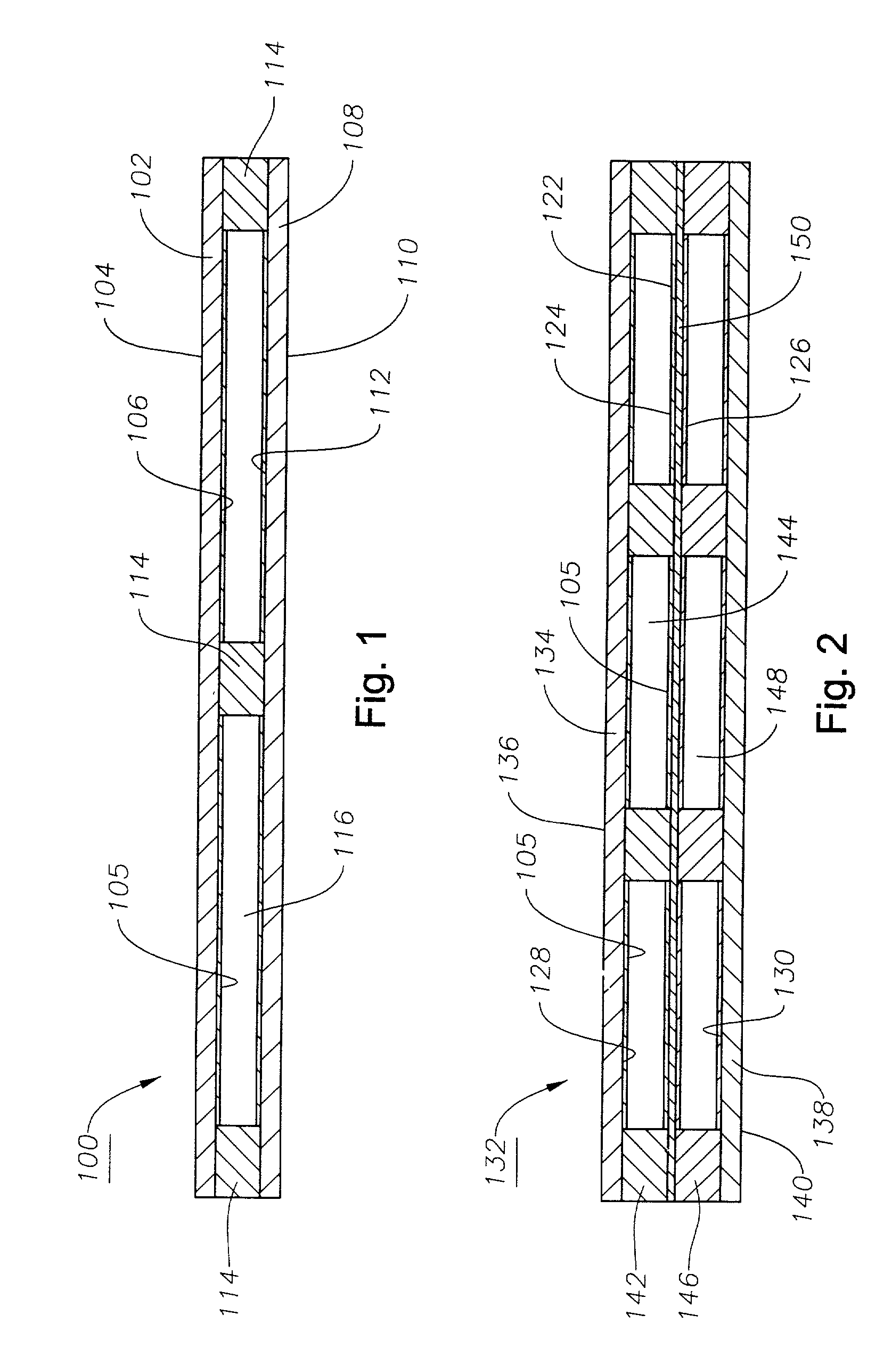

[0027] In a second embodiment shown in FIG. 2, a thermal decking 132 comprises a first panel 134 having an outside surface 136 and an inside surface 128. First panel 134 can be any desired thickness but is preferably about 1 / 2" thick 4' wide and 8' long. A second panel 138 has an outside surface 140 and an inside surface 130 that faces the inside surface 128 of the first panel 134. Inside surfaces 128 and 130 optionally may be covered with foil 105. The second panel 138 can also be of any desired thickness but is preferably about 1 / 4" thick 4' wide and 8' long or alternatively is about 1 / 2" thick 4' wide and 8' long. Positioned between the first panel 134 and the second panel 138 is a radiant barrier 122. The radiant barrier 122 is a panel with a top side 124 and a bottom side 126 such that the top side 124 faces the inside surface 128 of the first panel 134 and the bottom side 126 faces the inside surface 130 of the second panel 138. Top side 124 and bottom side 126 are covered wit...

first embodiment

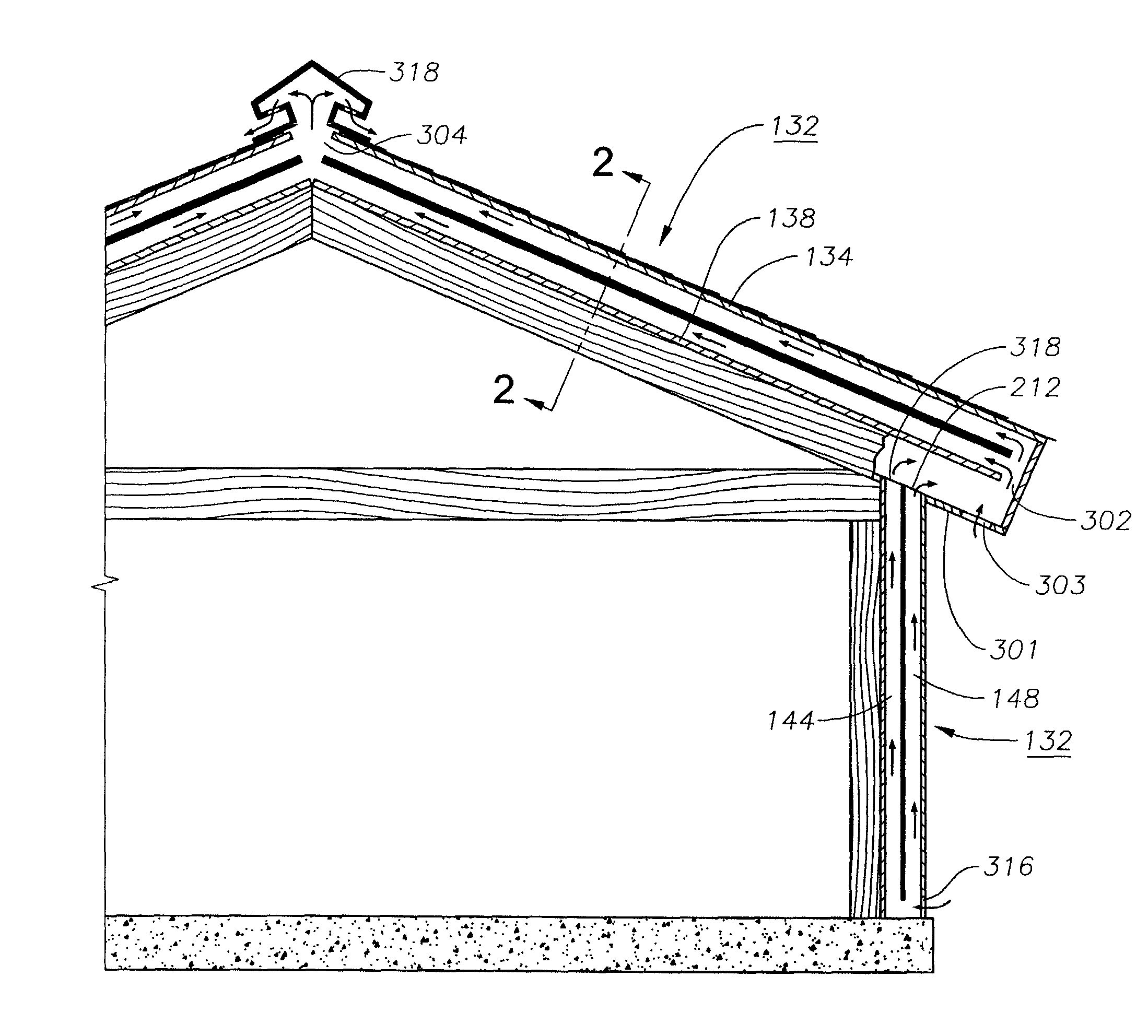

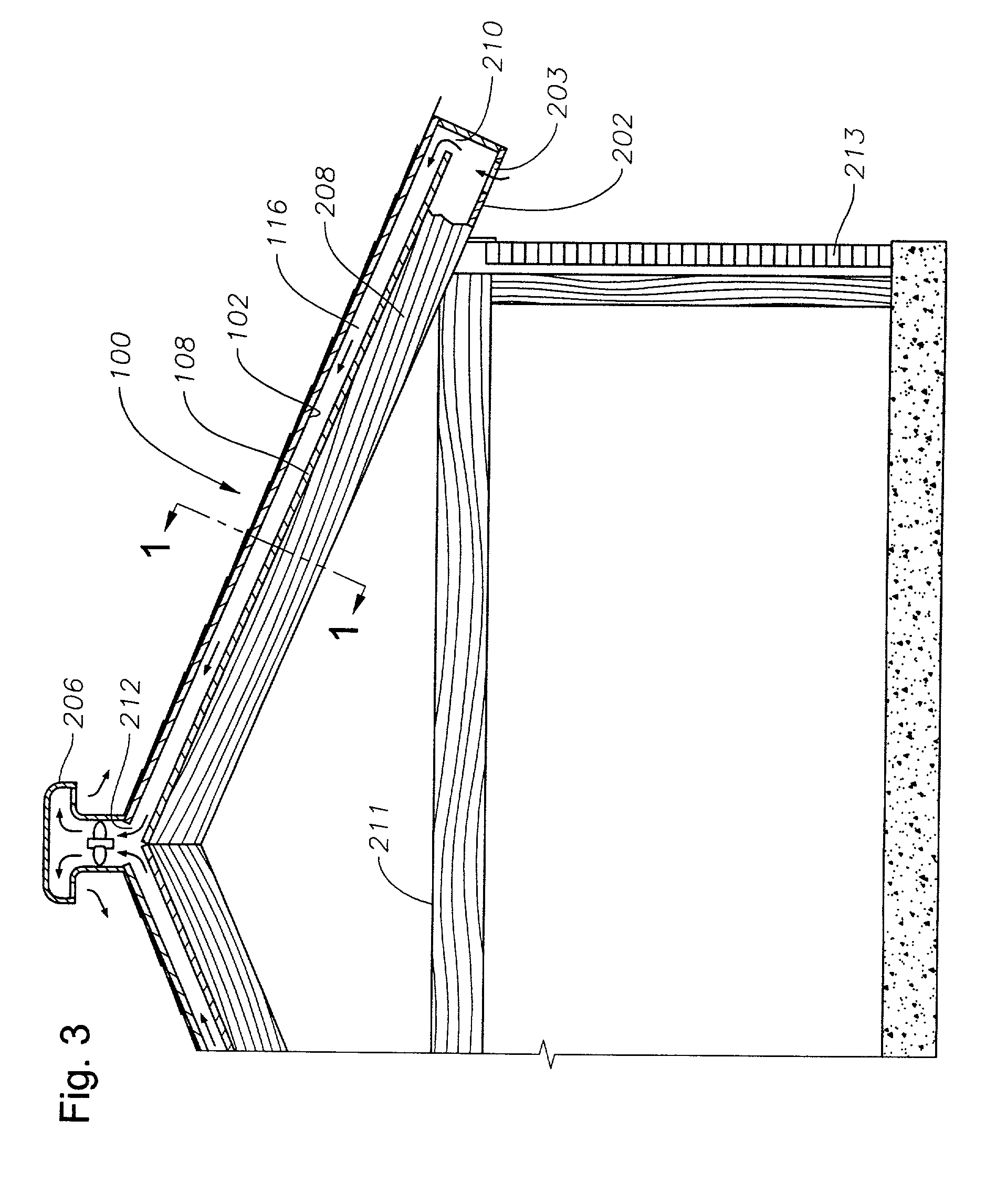

[0034] Referring to FIG. 4, thermal decking 132 could also be installed on conventional roof rafters in much the same manner as the thermal decking 100. If the thermal decking 132 is installed, then the second panel 138 and the radiant barrier 122 on the inlet side 302 may be cut at least 0.5 inch shorter than upper decking 136, leaving a portion of the first panel 134 extending past the second panel 138 and the radiant barrier 122 to create inlet 301. As in the first embodiment, inlet 302 is located in a soffit area 301 that has an opening 303 for air to flow in to inlet 302. A ridge vent 304 may be installed at outlet 304 on the ridge or peak of the roof to enhance air flow.

[0035] As shown in FIG. 4, thermal decking 100, or 132, could also be installed on the wall studs in place of the standard sheathing on side walls. The thermal decking 132 would be orientated such that an inlet 316 is near the base or foundation of the house while the outlet 318 is near the soffit area 202 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com