Wick, plate type heat pipe and container

a heat pipe and wicking technology, applied in the field of wicks, plate types of heat pipes, containers, etc., can solve the problems of water not being used as working fluid in the container made of aluminum, applying the above-mentioned method to seal the container, and difficult to form the container shown in fig. 11 which is made of copper by extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

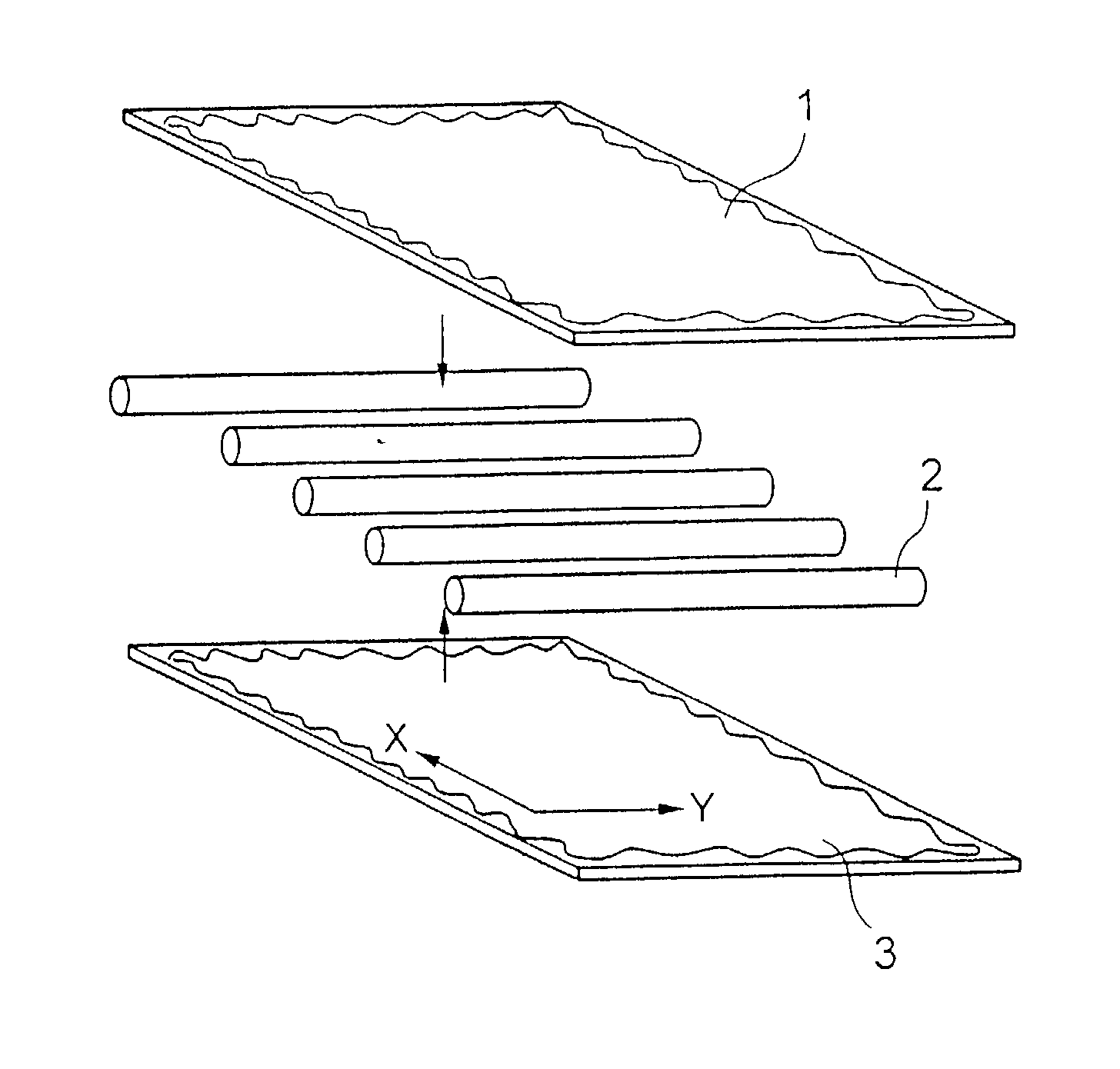

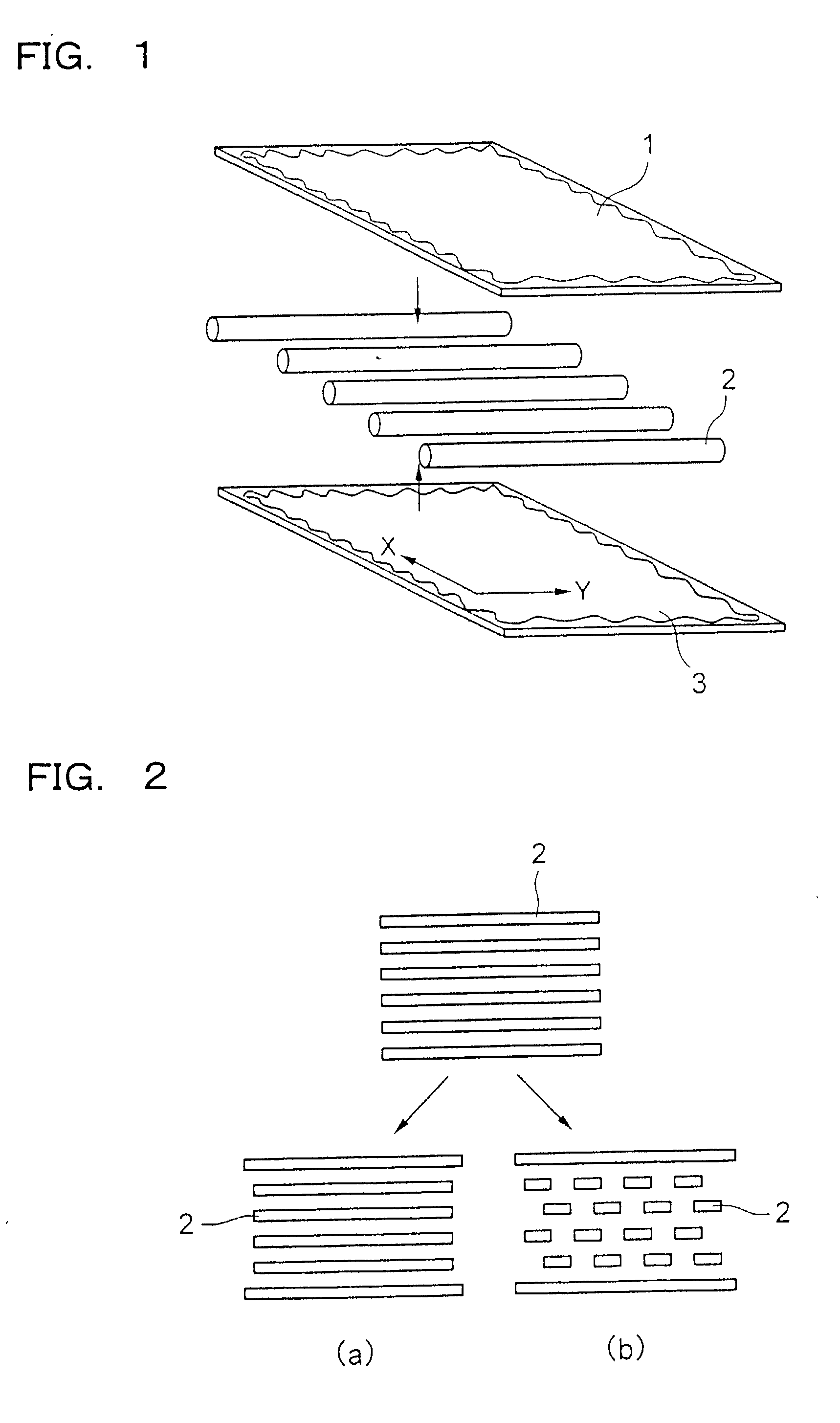

[0134] According to the present invention, a container of a plate type heat pipe of the present invention is formed by using two copper plate having a thickness of 0.2 mm, a width of 20 mm and length 50 mm, ten pieces of copper wire of a diameter of 0.2 mm.phi. and length of 50 mm, and 4 sheets of #200 screen meshes, as follows:

[0135] 10 pieces of the copper wires are placed in parallel each other with 2 mm pitch on one of the copper plate, and then 4 sheets of the meshes are interposed between the disposed wires and the other copper plate. Solder is applied in advance to the side portions of the copper wire to contact with the copper plate and the mesh, and each end of the meshes. A square bar is placed on each end of the copper plate so as to seal the container.

[0136] Then, thus formed copper plates with the copper wire and meshes placed and pinched by a fixing fig are introduced into a furnace as they are.

[0137] In addition, a small copper tube is interposed in advance so as to e...

example 2

[0138] The same material as in Example 1 except the following material are used and a plate type heat pipe of the present invention is formed in the same manner as in Example 1 except the following. More specifically, 4 sheets of the meshes are divided into respective 2 sheets. The group of copper wires placed in parallel are interposed between a set of 2 sheets of meshes, and then, thus formed copper wires and meshes are interposed by two copper plates to form a plate type thin heat pipe of the present invention having a width of 20 mm, a length of 50 mm, and a thickness of 1 mm. When a chip generating heat was cooled by thus formed plate type thin heat pipe of the present invention, the chip was effectively cooled.

example 3

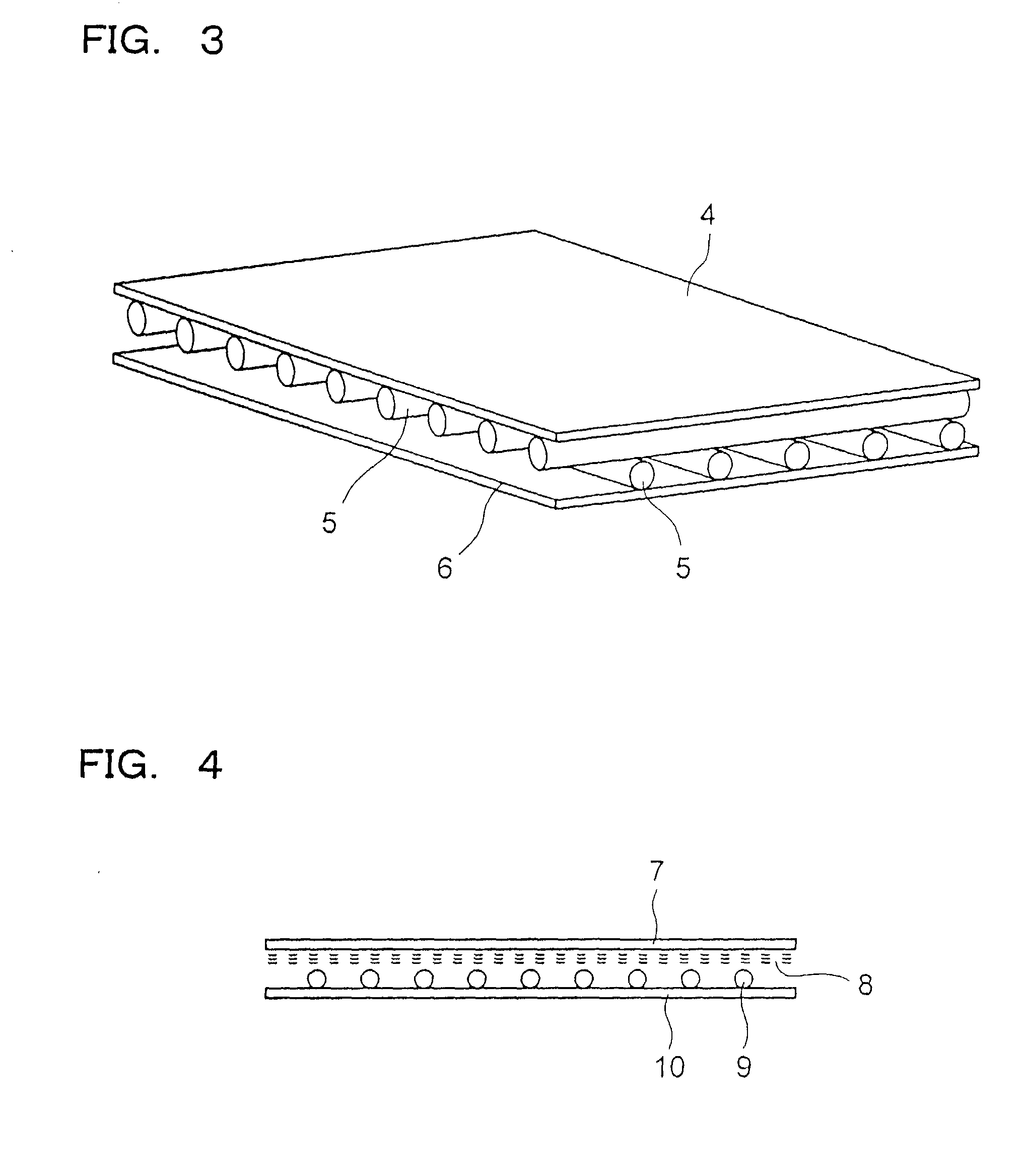

[0139] According to the present invention, the plate type heat pipe of the present invention schematically shown in FIG. 3 is formed by using two copper plate having a thickness of 0.2 mm, a width of 40 mm and a length 60 mm, 36 pieces of copper wire of a diameter of 0.3 mm.phi. and length of 60 mm, and 56 pieces of copper wire of a diameter of 0.3 mm.phi. and length of 40 mm, as follows:

[0140] Copper wires 5 are placed in parallel each other with 1 mm pitch on one of the copper plate 4. Solder is applied in advance to the side portions of the copper wire to contact with the copper plate. Copper wires are bundled before being cut to be the above mentioned size, and applied tensile force, and then pressed and adhered to the end portions of the copper placed below, thus forming a unit. In the same manner, another unit in which copper wires 5 are placed on the copper plate 5 is formed.

[0141] The above-mentioned two units are placed face to face in such manner the axis directions of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com