Scuff mark removal tool for floors

a technology for cleaning tools and floors, applied in carpet cleaners, cleaning machines, cleaning equipment, etc., can solve the problems of scuff marks on the floor surface, large floor surface scuff marks, and practical and efficient cleaning of large floor surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

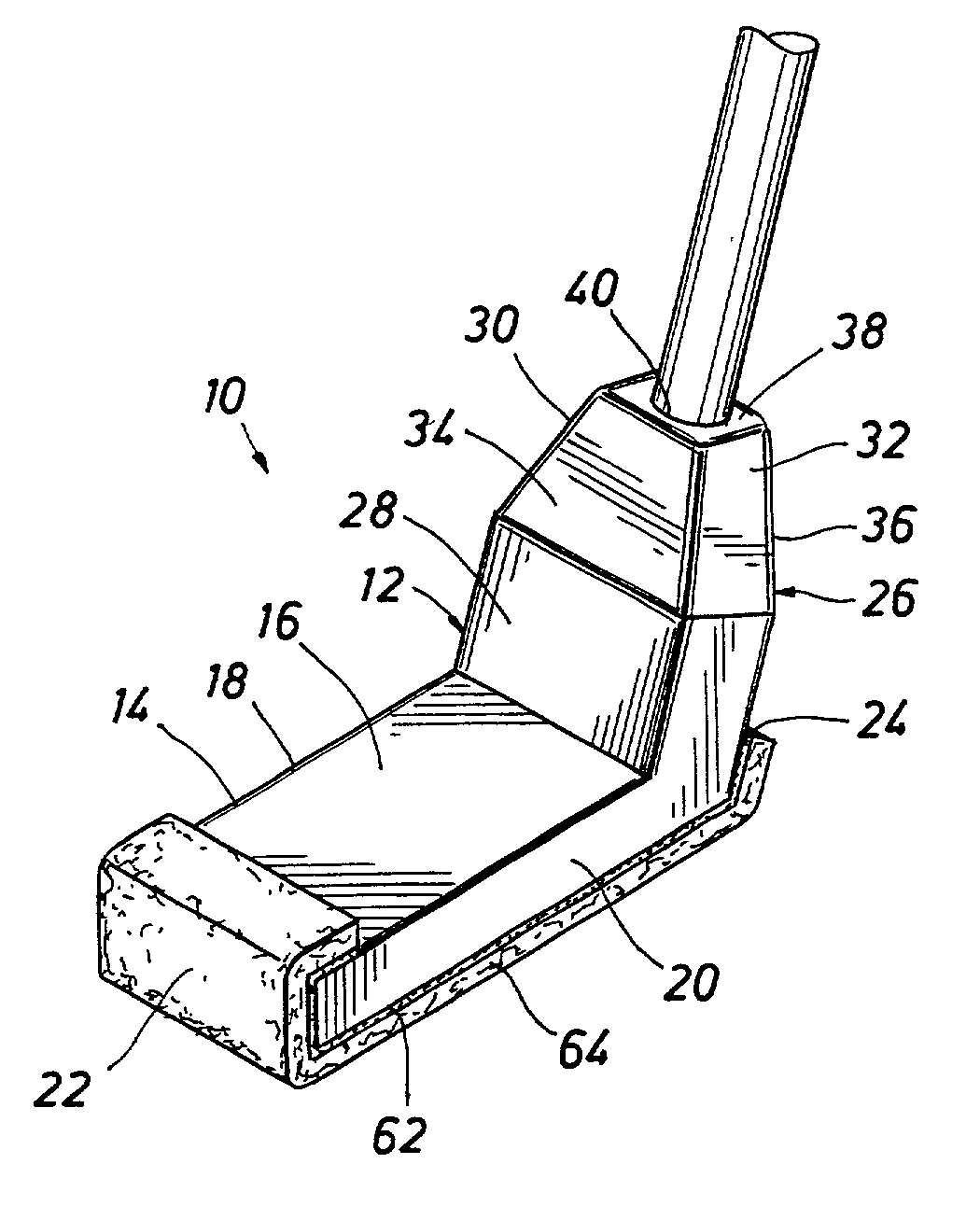

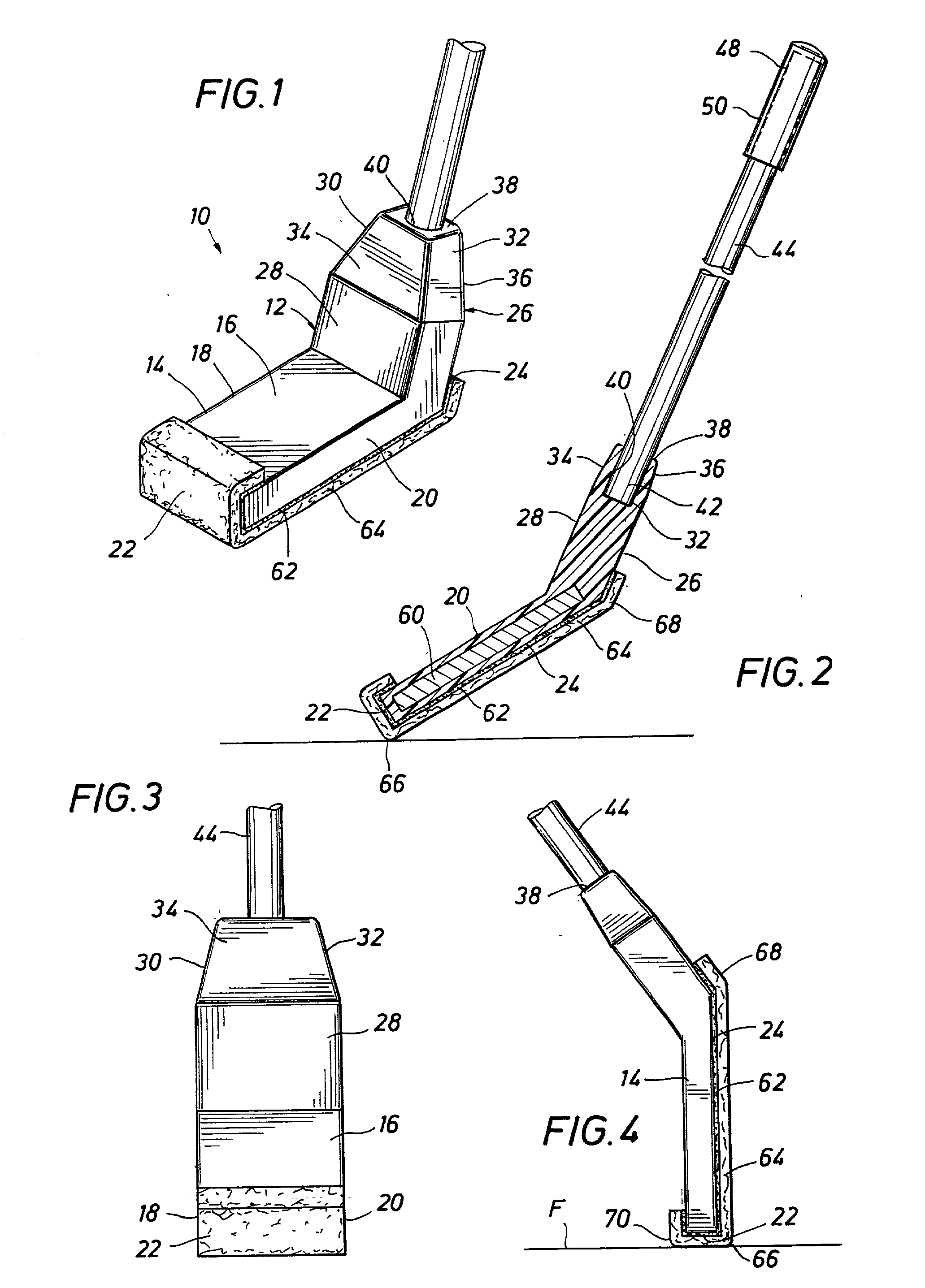

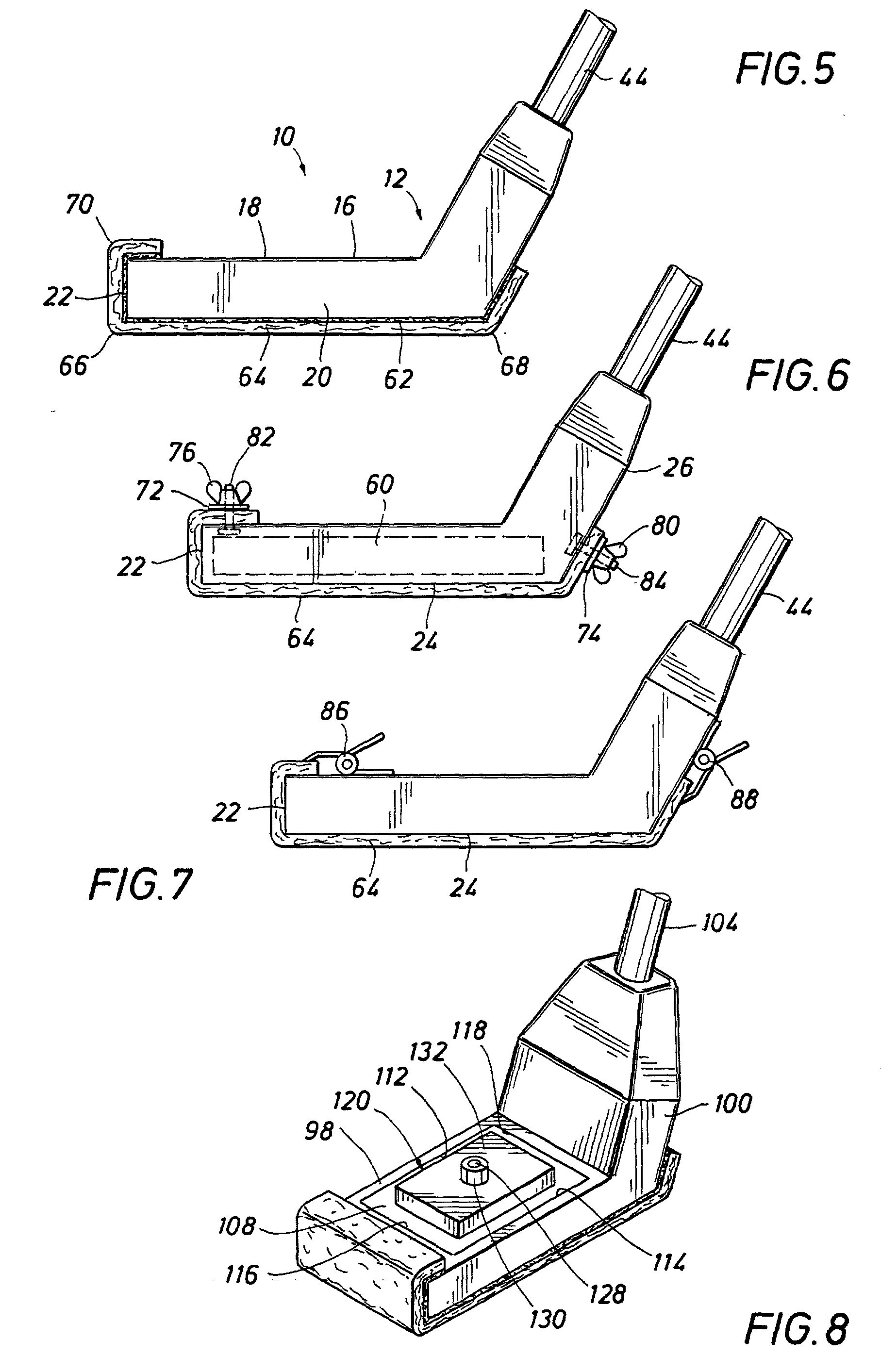

[0027] Referring now to the drawings and first to FIGS. 1-3, a manually utilized scuff mark removal device or tool embodying the principles of the present invention is shown generally at 10 and has an angulated head structure shown generally at 12. The angulated head structure 12 is generally composed of a polymer material which may be molded, but may be formed from a variety of other materials, such as aluminum alloy, wood, hard rubber, or the like. The angulated head structure 12 defines a pad support block 14 which, in FIGS. 1-3 is shown to be of generally rectangular configuration, defining a substantially planar top surface 16, parallel side surfaces 18 and 20 a front edge surface 22, a bottom generally~planar surface 24 and a rear surface 26 having intersection with the bottom generally planar surface 24. The rear surface 26 is preferably disposed in obtuse angular relationship with the bottom generally planar surface 24. The head structure 12 also defines an angulated handle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com